Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

These two flotation machines were developed in the mid-1980s and were similar to the Finnish Outokumpu OK flotation machines, while absorbing the advantages of the American Doyle-Oliver Flotation Machines. As shown. XCF-type flotation machine and KYF-type flotation machine supporting the use of both the structural characteristics similar to the same size. Are deep groove type, inflatable flotation machine, the impeller from the mixing pulp, circulating pulp and the role of scattered air, and thus wearing parts less wear and tear, the power than other types of flotation machine. Which XCF has self-absorption pulp function, can be used independently of the level of configuration. KYF flotation machine without self-absorption pulp capacity, operating intermediate products need to return the bubble pump, equipment configuration need to have a gap.

The two types of flotation machine design is a comprehensive analysis of the current large-scale flotation machine at home and abroad use experience and characteristics, by the Beijing Nonferrous Metallurgical Design Research Institute designed and developed into the inflatable flotation machine, is a new development at home and abroad GM Type one. Because it uses "U" -type tank and has a strong ability to stir, to avoid the deposition of coarse particles of minerals, make full use of the tank volume, according to the production process conditions to adjust the amount of inflation, which is conducive to mineral capture. Therefore, it is suitable for non-ferrous, ferrous metal minerals and non-metallic mineral selection, through the production practice proved that the use of inflatable flotation machine than the past use of ordinary flotation machine can save electricity 30% - 40%.

Product structure and principle:

Equipment structure and features:

The flotation machine uses a "U" trough, hollow shaft inflatable and suspended stator, in particular the use of a new impeller. This is a kind of cone and a kind of blade, which is similar to the centrifugal pump wheel with high specific speed, large amount of slag, small pressure, low power consumption and simple structure. A porous cylindrical air distributor is also provided in the impeller chamber to allow the air to be pre-selected evenly throughout most of the impeller blades, providing a larger slurry-air contact interface.

When the flotation machine is working, with the rotation of the impeller, the pulp in the tank is sucked from the bottom of the impeller to the impeller blades from the bottom of the tank through the bottom of the tank. At the same time, the low pressure air fed by the blower is passed through the hollow shaft and the air distributor of the impeller , By the stator steady flow and orientation into the entire slot. Bubble on the foam stabilized area, after enrichment process, the foam overflow from the overflow weir flow, into the bubble tank. There are two parts of the pulp to the lower part of the flow of the impeller, and then by the impeller stirring, re-wet formation of mineralized bubbles, the remaining pulp flow to the next tank, until the end of the tailings.

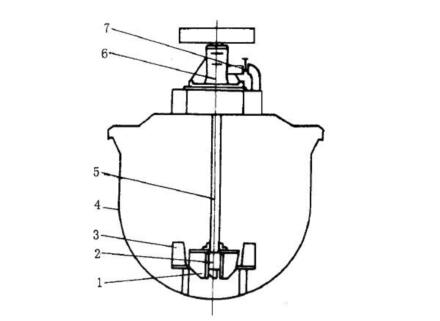

KYF Flotation Machine

1-impeller; 2-air dispenser; 3-stator; 4-tank body;

5-spindle; 6-bearing body; 7-air control valve

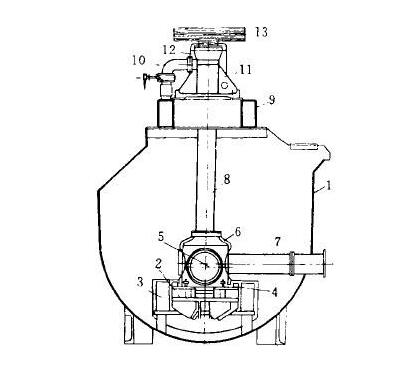

XCF Flotation Machine

1-tank; 2-impeller; 3-stator; 4-cover; 5-pipe; 6-center tube;

2- 8 - connecting pipe; 9 - beam; 10 - air regulating valve; 11 - bearing body; 12 - motor; 13 - transmission

working principle:

When the impeller rotates the impeller on the impeller to the mine and the mine, the tank slurry from the bottom of the bottom of the impeller from the bottom of the impeller into the leaves under the blade, at the same time, by the blower into the low pressure air through the distributor into the leaves under the impeller, The pulp and air are mixed thoroughly between the blades under the impeller and are discharged from the periphery of the blade under the impeller. The discharged slurry and air mixture, together with the pulp discharged from the upper blade, are fed into the tank by steady flow and orientation of the stator mounted around the impeller In the main pulp, the mineralized bubbles rise to the surface of the tank to form a foam layer, and the part of the slurry in the tank returns to the lower leaves of the impeller to circulate, and the other part enters the lower tank through the flow hole on the groove wall.

The flotation machine is inflated by the low pressure air from the blower, which enters the inner cavity of the bearing body from the inlet duct and then into the hollow shaft. The slurry is mixed with the air by the impeller and Stator plate impact, so that the air to form a small bubble, and the slurry into a mixture - mineralized bubbles. And then the bubbles rise to the bubble stabilization zone, after the enrichment process, the foam from the overflow weir from the overflow into the foam tank, but also part of the pulp to the lower part of the impeller, and then by the impeller stirring, re-mixed remineralized, mineralized bubbles And then rise to the bubble stability area, but also part of the pulp, flow to the next slot, until the end of the tailings.

This type of inflatable flotation machine has the following characteristics:

1, inflatable large, uniform gas dispersion, low energy consumption.

2, significant energy saving, than the general flotation machine can save 30% -50%.

3, the structure is simple, easy to repair; wear small, wearing parts costs can save 70% -80%.

4, pulp circulation performance is good, small consumption of pharmaceuticals, can reduce the consumption of 10% -15%.

5, "U" -shaped trough to reduce the phenomenon of the bottom of the tank body, the tank support reasonable, large span between the bearings, equipment, good stability.

6, low energy consumption, the unit capacity of the total power consumption (including fan) 25KW / m3 than the 6A flotation machine can save about 30-40%.

7, the air dispersion is good, uniform bubble dispersion, foam stability, flotation machine inflatable volume of 3 to 6 meters 3 / slot points.

8, ore particles suspended, due to the impeller stir strong, so that the slurry was fully stirred. Through different regions and stratified sampling, +80 mesh and other grain size in the flotation machine distributed evenly, to maintain a good suspension state, not sink.

9, the load from easy. Simulate the sudden power failure and then start the test proved that the flotation machine spindle to stop the rotation and continue to give the case of pulp, stop the supply of wind, after 15 hours and then start, flotation machine can immediately action, indicating that long parking can not To mine.

10, sorting effect is good. Proof of production in the short flotation time or the same circumstances, have reached or exceeded the original flotation index.

Use and configuration

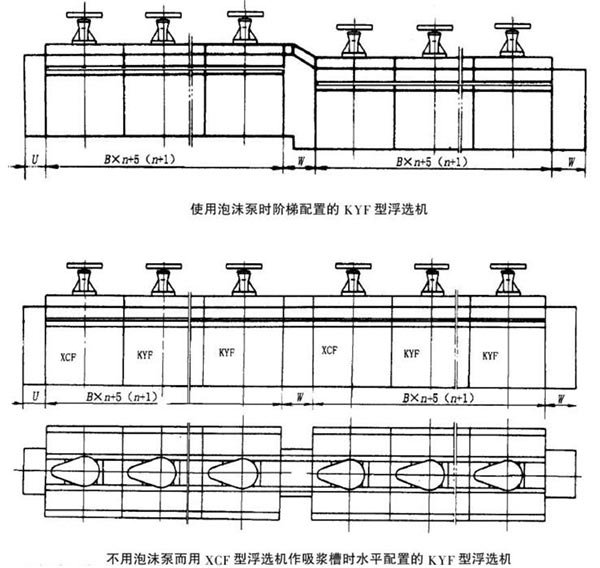

The flotation machine with a single slot, double slot, three slots, four slots, five slots, six slots, eight slots several units. Consists of several units. (That is, several operating areas) to become a big sort of homework. The first part is equipped with a tank and the tail is equipped with a discharge tank. Between the units are equipped with intermediate boxes. In addition, the flotation machine can not self-reflow back to the foam and pulp, so need to help pump back to the bubble, so that flotation machine full play flotation. This can save power consumption, thereby reducing production costs. Between each unit to be ladder configuration, height difference see figure. Between each flotation machine can also be used to connect the console board side to form a large operating platform, easy to walk and operate. In order to extend the tank, foam tank and impeller, the stator life, slot and impeller, stator lining with wear-resistant materials. The bottom of the tank body with a liner, the tank has a special request when the order can be made.

Ordering instructions

1, when ordering users need to order order configuration orders.

2, the order configuration map content:

(1) to the tank, the middle box, the number of discharge tank. The The The The The

(2) Number of slots: single slot, double slot. The The The The How many units, how many slots.

3, pulp acid, alkalinity, consider the lining of the performance, can not be lining.

4, the user if there are special requirements, please put forward when ordering.

The KYF flotation machine has a reasonable structure and a novel idea, so that it can obtain sufficient mixing strength and good bubble dispersion with slower impeller speed, and the "U" trough is used to reduce the trough bottom Coarse sediment minerals deposition, make full use of the volume of the pump, according to the production process conditions to adjust the amount of inflation, which is conducive to mineral capture, reduce the amount of pharmaceutical. KYF type flotation machine and can be combined with XCF flotation machine flotation unit, for the DC slot, advanced design. The spindle part of the side hanging in the rack, the bearing body structure is light, easy installation, transmission parts can be debugged, easy to maintain adjustment and maintenance.

Product specifications and technical parameters:

Mine flotation machine is widely used in copper, lead, zinc nickel, molybdenum, gold and other nonferrous metals, ferrous metals and non-metallic mineral rough selection, selection and anti-flotation operations.

Product specifications and technical parameters:

XCF inflatable flotation machine (can be self-absorption pulp capacity, can be set horizontally, without foam pump)

model | Effective volume(m3) | Processing capacity(m3/min) | Impeller diameter(mm) | Impeller speed(r. p. m) | Blower wind pressure(k p a) | Maximum inflatable volume(m3/m2.min) | Mixing motor power (k w) | Scraper motor power (k w) | weight( t ) |

XCF-1 | 1 | 0. 2-1 | 400 | 358 | ≥12. 6 | 2 | 5. 5 | 1. 1 | 1. 154 |

XCF-2 | 2 | 0. 4-2 | 470 | 331 | ≥14. 7 | 2 | 7. 5 | 1. 1 | 1. 653 |

XCF-3 | 3 | 0. 6-3 | 540 | 266 | ≥19. 8 | 2 | 11 | 1. 5 | 2. 259 |

XCF-4 | 4 | 1. 2-4 | 620 | 215 | ≥19. 8 | 2 | 15 | 1. 5 | 2. 669 |

XCF-8 | 8 | 3. 0-8 | 720 | 185 | ≥21. 6 | 2 | 22 | 1. 5 | 4. 435 |

XCF-16 | 16 | 4- 16 | 860 | 160 | ≥25. 5 | 2 | 37 | 1. 5 | 6. 568 |

XCF-24 | 24 | 4-24 | 950 | 153 | ≥30. 4 | 2 | 37 | 1. 5 | 8 |

XCF-38 | 38 | 10-38 | 1050 | 148 | ≥34. 3 | 2 | 45 | 1. 5 | 11 |

KYF type inflatable flotation machine

model | Effective volume(m3) | Processing capacity(m3/min) | Impeller diameter(mm) | Impeller speed(r. p. m) | Blower wind pressure | Maximum inflatable volume(m3/m2.min) | Mixing motor power (kw) | Scraper motor power (kw) | weight( t ) |

KYF-1 | 1 | 0. 2-1 | 340 | 281 | ≥12.6 | 2 | 4 | 1. 1 | 0. 826 |

KYF-2 | 2 | 0. 4-2 | 410 | 247 | ≥14.7 | 2 | 5. 5 | 1. 1 | 1. 419 |

KYF-3 | 3 | 0. 6-3 | 480 | 219 | ≥19.8 | 2 | 7. 5 | 1. 5 | 1. 885 |

KYF-4 | 4 | 1. 2-4 | 550 | 200 | ≥19.8 | 2 | 11 | 1. 5 | 2. 206 |

KYF-8 | 8 | 3. 0-8 | 630 | 175 | ≥21.6 | 2 | 15 | 1. 5 | 4. 190 |

KYF-16 | 16 | 4. 0-16 | 740 | 160 | ≥25.5 | 2 | 30 | 1. 5 | 6. 019 |

KYF-24 | 24 | 4. 0-24 | 800 | 150 | ≥30.4 | 2 | 30 | 1. 5 | 7. 5 |

KYF-38 | 38 | 10-38 | 880 | 138 | ≥34.3 | 2 | 37 | 1. 5 | 10. 3 |