Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Hammer crusher by high-speed rotation of the hammer and material collision broken material, it has a simple structure, crushing ratio, high production efficiency, can be used for dry and wet two forms of broken, ring hammer crusher for mining, cement , Coal, metallurgy, building materials, roads, fuel and other sectors of the medium hardness and brittle materials crushed. Ring hammer crusher can be adjusted according to user requirements grate gap, change the material size, to meet the different needs of different users.

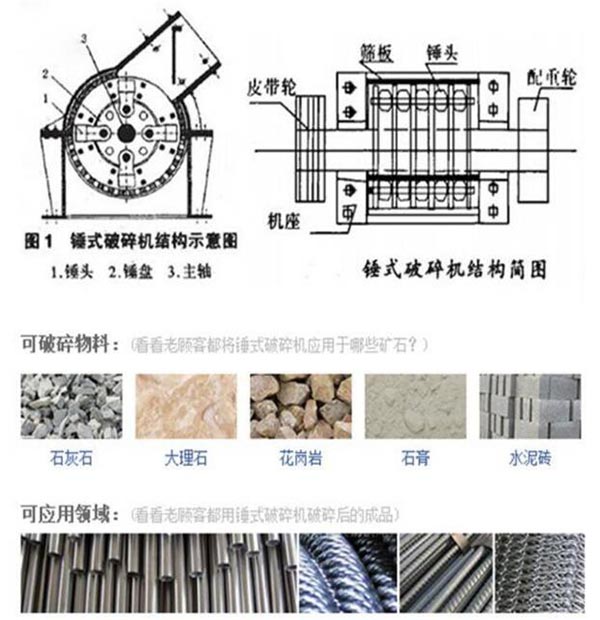

Product structure and principle:

Hammer crusher by the box, the rotor, hammer, counter-liner, sieve and other components. The motor drives the rotor to rotate at high speed in the crushing chamber. Material from the upper feed port into the machine, by the high-speed movement of the hammer blow, impact, shear, grinding and grinding. In the lower part of the rotor, a sieve plate is provided, and the particle size smaller than the size of the sieve is discharged through the sieve plate. The coarse grain size larger than the sieve size is retained on the sieve plate and continues to be hit and ground by the hammer. Outside the machine.

The rotor consists of a spindle, a disc, a pin and a hammer, a motor or a diesel engine, and a base bracket.

Hammer crusher (hammer broken), also known as hammer crusher for the destruction of a variety of hard and abrasive materials. Its (hammer crusher hammer) material compressive strength of not more than 100MPa, moisture content of less than 15%. The crushed material is coal, salt, chalk, gypsum, brick, limestone and so on. Also used to break the fiber structure, elastic and toughness of the broken wood, paper or broken asbestos cement waste to recover asbestos fiber and so on.

Hammer Crusher (Hammer) Main Uses:

This series of products for crushing coal, salt, white Asia, gypsum, alum, brick, tile, limestone and other brittle materials minerals. Used in railway, highway, cement, building materials, fire, ceramics, chemical and other industries, the material in the broken and crushed. The compressive strength of the machine material does not exceed 100 MPa and the humidity is not more than 15%.

Hammer crusher works:

The main working part of the hammer crusher is a rotor with a hammer (also known as a hammer). Hammer crusher rotor consists of spindle, disc, pin and hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. Material from the upper feed port into the machine, by the high-speed movement of the hammer blow, impact, shear, grinding and grinding. In the lower part of the rotor, a sieve plate is provided, and the particle size smaller than the size of the sieve is discharged through the sieve plate. The coarse grain size larger than the sieve size is retained on the sieve plate and continues to be hit and ground by the hammer. Outside the machine.

The hammer crusher has the following advantages:

1. Simple structure, compact size, small weight, low power consumption per unit of product.

2. Higher productivity, broken than large, small and uniform product size, was cube-style, excessive crushing phenomenon less.

3. Work continuously reliable, easy maintenance and repair, vulnerable parts easy to check and replace.

Product Application:

Hammer crushers are used to break all kinds of hard and abrasive materials. Its material compressive strength of not more than 100MPa, moisture content of less than 15%. The crushed material is coal, salt, chalk, gypsum, brick, limestone and so on. Also used to break the fiber structure, elastic and toughness of the broken wood, paper or broken asbestos cement waste to recover asbestos fiber and so on. In addition, hammer crusher can not only be used for crushing production lines, sand production lines, but also in the mineral processing line instead of cone crusher. The main working part of the hammer crusher is a rotor with a hammer (also known as a hammer). The rotor consists of a spindle, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. Material from the upper feed port into the machine, by the high-speed movement of the hammer blow, impact, shear, grinding and grinding. In the lower part of the rotor, a sieve plate is provided, and the particle size smaller than the size of the sieve is discharged through the sieve plate. The coarse grain size larger than the sieve size is retained on the sieve plate and continues to be hit and ground by the hammer. Outside the machine.

Product specifications and technical parameters:

Model specifications

Feed particle size(mm) | Material size(mm) | Production capacity(m3/h) | Motor power (kw) | total weight(t) | Dimensions (Length × width × height) (mm) | |

PcΦ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900×670×860 |

PCΦ-500×350 | ≤200 | ≤25 | 5-15 | 18.5 | 1.2 | 1200×1114×1114 |

PcΦ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200×1050×1200 |

PcΦ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310×1180×1310 |

PcΦ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600×1390×1575 |

PcΦ1000×1000 | ≤350 | ≤35 | 30-55 | 90 | 8 | 1800×1590×1775 |

PcΦ1250×1250 | ≤350 | ≤35 | 35-65 | 132 | 14 | 2060×1600×1890 |

PcΦ1400×1400 | ≤350 | ≤35 | 50-100 | 280 | 32 | 2365×1870×2220 |