Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Split mud, also known as cone grading machine, is a simple grading, desliming and enrichment equipment. Its shape is an inverted cone. In the center of the liquid set to the ore cylinder, the bottom of the cylinder into the liquid below a number of depth. The pulp is fed into the center cylinder along the tangential direction and is buffered out of the bottom edge. The effluent slurry flows radially toward the peripheral overflow weir. In this process, the coarse particles with settling velocity greater than the rate of rise of the flow will sink in the tank and be discharged through the bottom of the sand. The fine particles enter the overflow tank with the surface slurry. To the ore particle size is generally less than 2mm. The graded size is 75 μm or more.

The mud has a simple structure, easy to manufacture, no power and other advantages. As the cone volume is large, in the production process there are storage effect. At present, mainly used in the hydraulic grading machine before the ore off the mud, in order to improve the classification efficiency; and also installed in the grinding equipment before the ore concentration, dehydration, in order to improve the ore to the ore concentration; Mud to select the equipment before the control to the ore concentration and ore.

Product structure and principle:

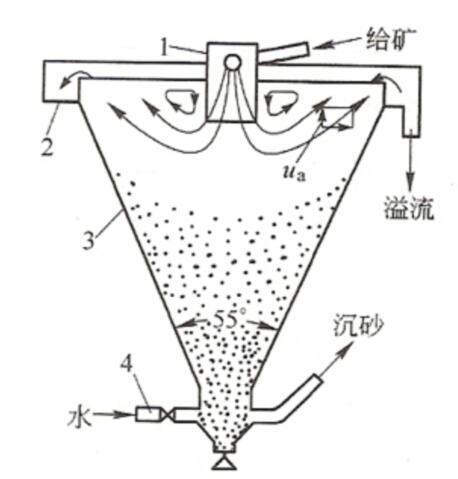

1 - to the ore pipe; 2 - ring overflow tank; 3 - cone; 4 - standby high - pressure water pipe

The shape of the dewatering bucket is an inverted cone. In the center of the liquid set to the ore cylinder, the bottom of the cylinder into the liquid below a number of depth.

working principle:

The pulp is fed into the center cylinder along the tangential direction and is buffered out of the bottom edge. The effluent slurry flows radially toward the peripheral overflow weir. In this process, the coarse particles with settling velocity greater than the rate of rise of the flow will sink in the tank and be discharged through the bottom of the sand. The fine particles enter the overflow tank with the surface slurry. To the ore particle size is generally less than 2mm. The graded size is 75 μm or more.

Degassing bucket is characterized by simple structure, no need to facilitate the operation of power. Now de-mud bucket mainly used in the hydraulic grading machine before the ore deslimation in order to improve the classification efficiency can also be used in the grinding equipment before the ore concentration, dehydration, improve the mill to the ore concentration, can also be used in a variety of mud Do not control the ore concentration before the equipment. As the demoulding bucket of the larger volume, in the production process also has the role of ore storage.

Product Application:

Mainly used in the hydraulic grading machine before the ore off the mud, in order to improve the classification efficiency; and also installed in the grinding equipment before the ore concentration, dehydration, in order to improve the mine to the ore concentration; also used in a variety of mud Select the equipment before the control to the ore concentration and ore.

Product specifications and technical parameters:

Specifications (Diameter mm) | φ1000 | φ1500 | φ2000 | φ2500 | φ3000 |

Settlement area m2 | 0.75 | 2 | 3 | 4.9 | 7 |

Volume (m3) | 0.27 | 0.83 | 2.27 | 4 | 7 |

Drilling diameter (mm) | φ25 | φ40 | φ50 | φ60 | φ70 |

Concentration (%) | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 |

Grain size (mm) | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

Processing capacity (t / m2.h) | 1.5~0mm粒度为2~2.16t/m2.h 0.074~0mm粒度为0.19~0.25t/m2.h | ||||

Mine pipe (mm) | φ120 | φ150 | φ150 | φ150 | φ150 |

Degreasing effect (%) | 33~45 | 33~45 | 33~45 | 33~45 | 33~45 |

Weight (kg) | 500 | 980 | 1483 | 1850 | 2100 |

Dimensions (diameter * high) | Φ1265*1529 | Φ1804*2115 | Φ2404*2715 | Φ2906*3328 | Φ3406*3925 |