Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

6-S shaker is one of the main equipment of gravity ore dressing. It is widely used in sorting tungsten, tin, tantalum and niobium and other rare metals and precious metal ores. Can also be used to sort iron, manganese ore and coal. When dealing with tungsten, tin and other minerals, the effective recovery of the shaker size range of 2-0.02 mm.

Product structure and principle:

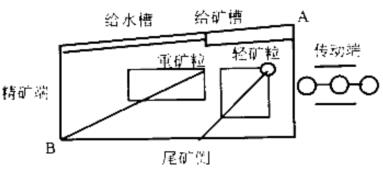

The beneficiation process of the shaker is carried out on a bed with a reclining (Fig. 1).

The work of the shaker

The trough is fed and the horizontal flushing water is supplied from the sump so that the fines are stratified by gravity and frictional force under the action of inertia and frictional force generated by reciprocating asymmetric motion of gravity and transverse water, Along the bed for longitudinal movement and along the inclined bed for lateral movement. Therefore, the different gravity and particle size of the ore particles along the direction of their respective gradually from the A side to the B side fan-shaped flow, respectively, from the concentrate and tailings side of the different areas of discharge, and finally divided into concentrates, mines and tail mine.

According to the different location of the ore, shaker can be divided into the right type shaker and left shaker two forms. The right-hand shaker to the mine position for the swing mechanism on the right side, left-style shaker to the mine position on the left,

6-S shaker with high ore ratio, the selection of high efficiency, easy to care, easy to adjust the stroke. The balance of the bed can be maintained while changing the lateral slope and stroke, the spring is placed in the box, compact, and the final concentrate and final tailings are obtained at one time.

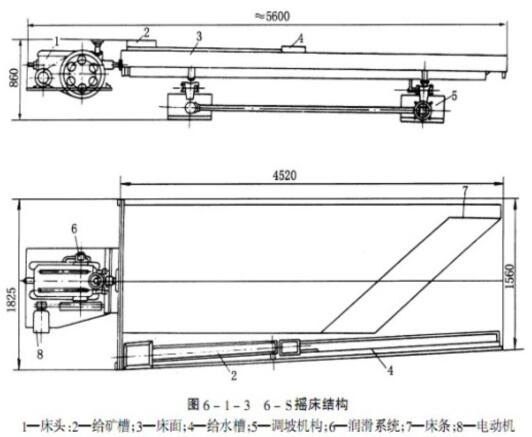

The shaker is mainly composed of eight parts: bed head, motor, windshield, bed, mine, sink, rework and lubrication system (Figure 2).

The rocker 6 drives the crankshaft 7 to rotate, the rocker 5 moves up and down, and the rocker 6 moves downward, the bracket 6 urges the rear axle 11 and the reciprocating lever 2 to move rearwardly, and the spring 9 is compressed The The bed is connected through the linkage block 1 and the reciprocating rod 2, so at this time also make the bed for back movement, when the rocker upward movement, due to the tension of the spring to push the bed with the forward movement.

During the forward movement of the bed, the angle between the brackets is changed from big to small, and the horizontal movement speed of the brackets is changed from small to large. So the bed of the forward movement that is slow and fast, and vice versa in the bed back, then by the fast and slow resulting in the equivalent of movement, so that the material on the bed to move forward, and by the proportion of sorting.

The bed shape is a right angle trapezoid, in the wooden frame, the wood along the oblique (with the axis angle of 450) spell plane. Bedside sub-paint gray carved bed and rubber bed surface two. Paint gray groove groove bed for sorting fine mud, rubber bed surface is used for sorting rough ore. The shaker table for selecting fine mud is tilted downward by about 0.50 in the longitudinal direction. The shaker for sorting coarse sand is tilted in the vertical direction by 10-20 and raised in the concentrate side. The length of the longitudinal slope is adjusted by the bolts on the support mechanism.

The bed is supported by shaking support on the slope adjustment mechanism. (Figure 4) shaking support to make the bed in the vertical plane for the arc ups and downs before and after the reciprocating movement. Shake support channel is fixed on the adjustment seat plate, when the hand wheel through the adjustment screw to adjust the seat plate in the saddle seat on the rotation, you can adjust the bed tilt.

The installation of the shaker:

Before installation, press the foundation diagram (see below) to pour the cement and embed the anchor bolts. The installation should pay attention to the need to make two sets of the slope of the 360 mm radius of the center of the center of the bed and the center of the bed with the center of the three in the same plane, or tilt in the bed, it will accelerate the wear of copper sets, and even reciprocating Rod broken. As for the linkage seat and the bed of the traction screw height error, you can adjust the bolt under the box to eliminate it.

The shaker has been in the factory when the empty load debugging operation qualified, the user should be installed in the equipment after two hours of empty load debugging operation, and check the following: start the process of running the motor is normal; parts of the contact And friction joint surface wear; whether there is abnormal noise; lubrication is normal and so on. Before the load test. After 24 hours and then check the above items.

Bed in the storage and handling should pay special attention to prevent any direction of deformation, to prohibit exposure in the sun, rain to wet.

Description:

1, the figure is the right-hand shaker installation map and left-style shaker installation size only the same as the vertical symmetry of the bed.

2, shaker installation center line position according to Figure 6-1-8 layout construction.

3, concentrates, in the mine, tailings, mining chute with brick and cement mortar masonry, chute bottom wall with cement mortar trowel, the construction of the actual situation by the tail of the tail at the tail sand trench.

4, the secondary grouting layer of not less than 30mm, the basic size of the figure are the actual installation size, secondary grouting to find the level of the floor, the construction of their own considerations.

Product Application:

The main purpose:

Glass steel shaker is widely used in tungsten, tin, lead, zinc, gold, silver, tantalum, niobium, monazite, zircon, ilmenite and other mineral ore or sand ore concentrator in dealing with 3-0.019mm granular ore Of rough selection and selected operations.

main feature:

Glass fiber reinforced concrete shaker has a large processing capacity; high recovery rate of mineral processing; wide adaptability and other characteristics, especially the concentrate is relatively stable, mineral concentrates, ore, tailings with clear, when the ore concentration, When the change occurs, the sorting situation is stable, so the operation and management is convenient.

Main structure:

The glass fiber reinforced concrete shaker consists of a steel frame and a face-to-face epoxy resin diabase casting material bed surface, a support shaker's foot, a slope adjustment mechanism and a reciprocating drive shaker.

Product specifications and technical parameters:

Equipment type | Shaking bed4500X1800 | ||||

project name | unit | Rough ore | In the mine | Mud | |

Bed size | Length | mm | 4500 | 4500 | 4500 |

Drive width | mm | 1830 | 1830 | 1830 | |

Concentrate wide | mm | 1500 | 1500 | 1500 | |

Processing particle size | mm | 3-0.5 | 0.5-0.1 | <0.1 | |

Processing capacity | t/d | 24-52 | 16-36 | 8-15 | |

Concentration of ore | % | 25-38 | 15-25 | 10-20 | |

stroke | mm | 16-20 | 12-14 | 8-10 | |

Red times | 次/分 | 280-300 | 300-330 | 320-350 | |

Cleaning water | t/h | 1-1.5 | 0.8-1.2 | 0.6-1 | |

Horizontal gradient | 0 | 2.5-4.5 | 1.5-2.5 | 0.5-1.5 | |

Vertical slope | 0 | 1-1.5 | 0.5-1 | 0.5 | |

Motor Power | KW | 1.1 | 1.1 | 1.1 | |

Bed section shape | Obtuse angle triangle | Right angle triangle | Acute angle triangle | ||

total weight | Kg | 1100 | 1100 | 1100 | |

Transmission mechanism | Eccentric link mechanism or cam lever mechanism | ||||

According to the different location of the ore, shaker can be divided into left-type shaker and right-type shaker two forms. Standing on the side of the shaking bed to look forward to the waiter, the left side of the feed for the left-style shaker, the right side of the feed for the right-style shaker.