Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Jaw crusher, with a large crushing ratio, product size uniformity, simple structure, reliable, easy maintenance, operating costs and other economic characteristics. Jaw crusher is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industry and many other departments, broken compressive strength of not more than 320 MPa of various materials.

Jaw crusher - also known as tiger's mouth. Because of this simple structure of the crusher, reliable, so it is widely used. It is used to crush hard and hard materials. In the concentrator, as a rough and broken equipment.

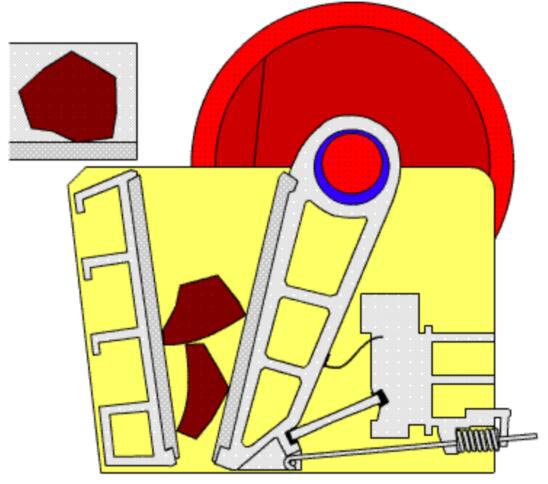

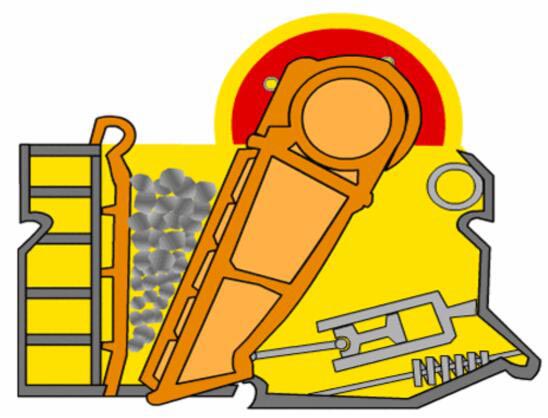

Jaw crusher broken ore process, adding to the jaw crusher crushing chamber (by the fixed jaw plate and movable jaw plate space) in the material, because the moving jaw plate for cyclical reciprocating swing, when the moving jaw plate near When the jaw is fixed, the material is crushed by crushing, splitting and bending. When the jaw plate from the fixed jaw plate, has been broken to less than the size of the mine discharge of the material, by its weight from the lower discharge port discharge. Located in the upper part of the crushing chamber has not broken to a small enough material, then fell to the lower part of the crushing chamber, again by the jaw plate and continue to be broken.

Product structure and principle:

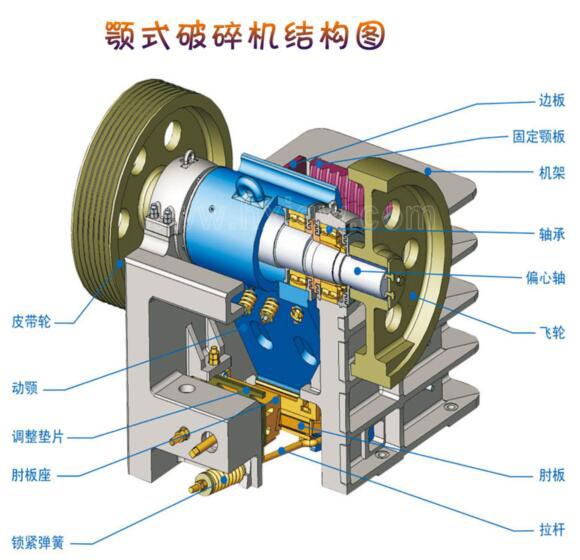

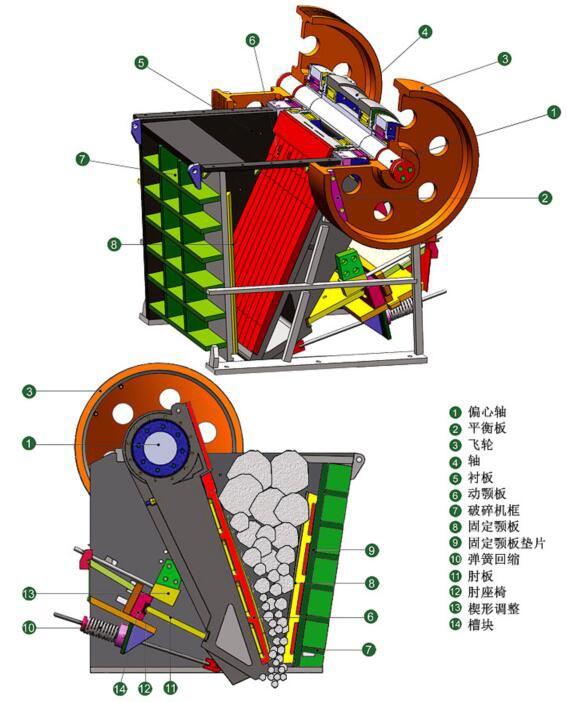

Jaw crusher (jaw broken) Structure Overview:

Jaw crusher (jaw broken) mainly by the fixed body, rotating body, insurance devices, adjust the device and other parts.

1, fixed body: jaw crusher (jaw broken) fixed body of the main components of the rack, rack manufacturing process there are two: medium carbon steel casting frame and medium carbon steel plate welding rack. The welding rack is based on the original casting frame and adds a number of ribs, and through strict quality control and specific process requirements, to achieve the same effect with the casting frame. In order to prevent serious wear on the side walls of the rack, the guards are provided on the left and right sides of the crushing chamber and are free to be replaced.

2, jaw broken body: by the moving jaw, eccentric shaft, bearings, pulleys and other parts, is the jaw crusher (jaw broken) drive and bear the main part.

2.1, moving jaw by the moving jaw bracket and movable jaw plate and other components, jaw broken jaw bracket with 35 # cast steel, and after quenching and tempering treatment.

2.2, jaw broken machine eccentric shaft by the 45 # steel car system, and after quenched and tempered.

2.3, bearing double row radial spherical roller bearings, with fine-tuning, bearing large, durable features.

2.4, jaw plate activities and fixed two, in order to improve the crushing effect, the surface using optimized tooth, the material used ZGMn13 with high hardness, wear, the use of good results.

3, adjust the device: the device is used to adjust the size of the discharge port size, control (jaw broken) jaw crusher material size. I jaw crusher (jaw broken) adjustment mechanism in two forms: to improve the wedge and the top rod gasket, easy to adjust and flexible, to achieve stepless adjustment.

The size of the coarse-grained scale is retained on the sieve plate and continues to be hammered and ground, and finally discharged through the sieve plate.

(Jaw broken) jaw crusher working principle:

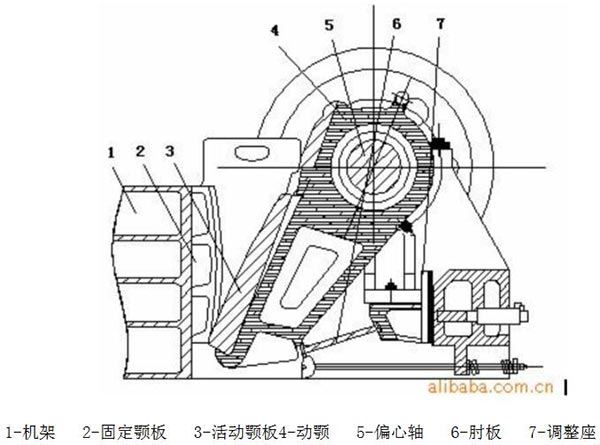

Jaw crusher (jaw broken) The structure of the main frame, eccentric shaft, large pulley, flywheel, moving jaw, side guards, brackets, elbow rear seat, split screw, reset the spring, fixed jaw plate and activities Jaw plate and other components, which also play a role in the brackets.

The series of jaw crusher (jaw broken) broken way for the song squeeze type, the motor drive belt and pulley, through the eccentric shaft to move the jaw up and down movement, when the moving jaw when the elbow and moving jaw angle between the larger, So as to promote the jaw plate to the jaw plate close to the same time the material was squeezed, rubbing, grinding and other multiple broken; when the moving jaw down, the brackets and moving jaws between the smaller angle, moving jaw plate in the rod, spring Under the action of the jaw plate, then broken material from the crushing chamber discharge, with the motor continuous rotation crusher jaw for cyclical crushing and nesting, the crusher to achieve mass production.

Jaw crusher (jaw broken) Features:

Jaw broken broken cavity deep and no dead zone, improve the feed capacity and yield;

2. Jaw broken broken than large, uniform product size;

3. Gasket-type discharge port adjustment device, reliable and convenient, large adjustment range, increasing the flexibility of the equipment;

4. Lubrication system is safe and reliable, easy parts replacement, maintenance workload is small;

5. Simple structure, reliable work, low operating costs.

6. Energy-saving equipment: 15% to 30% energy saving, more than double the system energy;

7. Discharge port adjustment range, to meet the requirements of different users;

8. Low noise, less dust.

Simple swing jaw crusher is mainly composed of rack and support device, broken ore working mechanism, transmission mechanism, safety device and discharge port adjustment device and other parts.

Complex swing jaw crusher is mainly used for ore in the broken. But in the small and medium-sized concentrator, but also as the first paragraph of the mine equipment, the mine mouth to the width of up to 900mm, the mine mouth width of 10-150mm, productivity of 1-450t / h. The crusher of this crusher is also an eccentric shaft, so the connecting rod is combined with the moving jaw. The movable jaw plate is directly suspended on the eccentric shaft by ball bearing. The eccentric shaft is supported on two ball bearings on the frame. The size of the discharge mouth is adjusted by wedge, and the brackets are only one piece. Moving jaw and jaw, the surface is curved. Other parts are similar to simple swing jaw craters. When the eccentric shaft is rotated, the upper movement trajectory is circular and the lower end is elliptical. It is called complex swing. It is in addition to crushing the role of ore, there are grinding off the role. So the productivity is high, energy oil consumption is also less. But the ore over crushing phenomenon is more serious, liner wear is also faster.

Jaw crusher performance advantages:

1. Broken process of advanced, energy efficient

Complex pendulum jaw crusher using the most advanced crushing process, the use of advanced digital components processing equipment, so that the internal structure of precision. Deep cavity broken no dead zone, the material in the crushing chamber does not occur blocking material phenomenon, improve the production efficiency. Stand-alone energy saving 15% to 30%, more than double the system energy.

2. The use of high-quality materials, high wear resistance parts

Parts use the most high-end production of high-quality materials, enhance the parts of the compression and wear resistance, reduce a certain wear and tear, extending the life of the entire equipment. Which moving jaw with high-quality cast steel components, eccentric shaft with forging processing, etc., so that equipment reliability increases, efficient and durable.

3. Flexible equipment, wide range of applications

Discharge port adjustment range, increasing the flexibility of the device to meet the needs of a variety of user processing. And the equipment structure is reasonable, covers an area of small, in a limited space can play the greatest role. Therefore, widely used in many industries in a variety of crushing process.

4. Simple structure easy to operate, easy maintenance

After a reasonable design, while improving the performance of the machine at the same time, make the overall structure of the device simple and efficient, fragmentation enhanced. The entire equipment in the use of simple operation, so that the daily maintenance work more convenient and reduce the downtime maintenance time.

(Jaw broken) jaw crusher production Note:

1, should carefully check the bearing lubrication is good, bearing the brackets connected to whether there is enough grease.

2, should carefully check all the fasteners are fully tightened.

3, the protective device is good, found unsafe phenomenon, should be immediately eliminated.

4, check the jaw broken broken cavity with or without debris, if any should be immediately eliminated.

(B) (jaw broken) jaw crusher start

1, after inspection, to prove that the machine and the transmission part of the normal, can start.

2, the machine can only start without load.

3, after the start, if found to have abnormal circumstances, should immediately stop, to be identified because the exclusion of hidden danger, can start again.

(3) (jaw broken) jaw crusher maintenance and use

1, (jaw broken) jaw crusher after the normal operation, before feeding.

2, to be jaw crushed material should be evenly added into the crushing chamber, and should avoid the side of the feed, to prevent the sudden change in load or sudden increase.

3, in normal working conditions, the bearing temperature should not exceed 30 ℃, the maximum temperature shall not exceed 70 ℃, or should immediately stop to identify the cause to be eliminated.

4, before stopping, should stop the feeding, to be broken cavity was completely broken material after the empty, before turning off the motor.

5, in use, if due to broken material within the cavity caused by downtime, should immediately turn off the motor, the material must be excluded before re-use.

6, one end of the jaw worn after the use of U-turn.

(4) (jaw broken) jaw crusher lubrication

1, often pay attention to timely friction surface lubrication work, can guarantee the normal operation of the machine and extend the service life.

2, the machine used by the grease, should be based on the use of location, temperature and other conditions to decide, generally can be calcium, sodium or calcium sodium grease.

3, adding the bearing seat grease for its volume of 40-70%, every three months must be replaced once; for new oil must be clean with gasoline or kerosene cleaning bearing and bearing dirt.

4, brackets and elbow plate pad contact before the machine starts, you must add grease.

(Jaw broken) jaw crusher repair method:

In order to ensure (jaw) jaw crusher normal work, in addition to correct operation, must be planned maintenance, including routine maintenance inspection, minor repair, repair and overhaul.

(1) minor repair: the main contents include inspection and repair adjustment device, high-speed discharge port gap, the wear of the liner U-turn or replacement. Maintenance of transmission parts, lubrication systems and replacement of lubricants. Minor repair period of 1-3 months or so.

(2) in the repair: In addition to the small repair of all the work, but also including the replacement of thrust plate, liner, check and repair pad and so on. The repair cycle is generally about 1-2 years.

(3) overhaul: In addition to the repair of all the work, but also including the replacement or turning eccentric shaft and moving jaw mandrel, casting the upper part of the connecting rod of the Babbitt, replace or repair the wear parts. Overhaul cycle is generally about 5 years.

Product Application:

1, the series jaw crusher (jaw broken) is mainly used for metallurgy, mining, chemical, cement, construction, refractory materials and ceramics and other industrial sectors for the broken and crushed all kinds of hard minerals and rocks.

2, the series jaw crusher (jaw broken) is most suitable for crushing compressive strength of not more than 320MPa (MPa) of various soft and hard ore, the maximum mass of broken material shall not be greater than the technical parameters specified in the table.

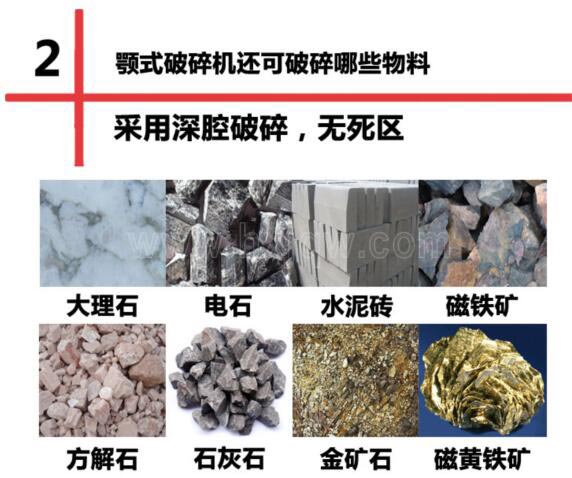

(Jaw broken) jaw crusher production of available materials and broken stone List:

Product specifications and technical parameters:

Specifications Model | Inlet sizemm | Maximum charge sizemm | Yieldt/h | Main bearing speed r/min | Outlet adjustment rangemm | Matching motor | Dimensions (L×W×H)mm | weight(No motor)kg | ||

long | width | model | powerKW | |||||||

PE150×250 | 250 | 150 | 125 | 1~3 | 285 | 10~40 | Y132S-4 | 5.5 | 875×745×935 | 1160 |

PE250×400 | 400 | 250 | 200 | 5~20 | 300 | 20~80 | Y180L-6 | 15 | 1410×1310×1386 | 2572 |

PEX150×750 | 750 | 150 | 120 | 8~35 | 320 | 10~40 | Y160L-4 | 15 | 1280×1610×1081 | 3350 |

PEX200×1000 | 1000 | 200 | 160 | 12~50 | 320 | 10~40 | Y200L-6 | 22 | 1530×1810×1250 | 4930 |

PE400×600 | 600 | 400 | 350 | 14~36 | 250 | 40~100 | Y250M-6 | 30 | 1700×1732×1658 | 5800 |

PEX250×750 | 750 | 250 | 210 | 15~45 | 300 | 15~50 | Y225M-6 | 30 | 1695×1920×1648 | 5000 |

PEX250×1000 | 1000 | 250 | 210 | 15~50 | 330 | 20~50 | Y250M-6 | 30 | 1550×1990×1370 | 6800 |

PEX250×1200 | 1200 | 250 | 210 | 20~70 | 320 | 20~60 | Y280S-6 | 45 | 1670×2190×1430 | 9000 |

PEX300×1300 | 1300 | 300 | 250 | 20~90 | 330 | 20~80 | Y280M-6 | 55 | 1780×2400×1720 | 11000 |

PE500×750 | 750 | 500 | 400 | 30~80 | 250 | 50~120 | Y280M-6 | 55 | 1900×1876×1821 | 9000 |

PE600×900 | 900 | 600 | 480 | 56~192 | 250 | 75~200 | Y315S-6 | 75 | 2280×2245×2320 | 18900 |

PE750×1060 | 1060 | 750 | 630 | 110~242 | 250 | 80~140 | Y315M-8 | 90 | 2531×2370×2783 | 29600 |

PE900×1200 | 1200 | 900 | 650 | 180~350 | 180 | 100~250 | JR126-6 | 110 | 5000×4471×3280 | 55000 |