Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

The double-roll crusher is one of the oldest crushing machines. It has the advantages of simple structure, less crushing phenomenon when broken, and the shape, size and arrangement of the teeth on the roll surface can be changed according to the material properties. Due to these advantages, It is still used in cement clinker, coal, coke, slag, slag, gypsum, clay, salt, chemical raw materials and other departments, and has new improvements and development. The crusher is mainly used in the ore, crushing operations, but because of the large area, low production capacity, in the metallurgical and mining industry has been replaced by cone crusher.

Two-roll crusher work reliable, simple maintenance, low operating costs, adjustable size of the nesting size. According to the number of rollers can be divided into double-roll crusher and four-roll crusher.

Double roll crusher for compressive strength of less than 150Mpa, less than 20% of the water in the hard and soft materials in the broken and crushing operations. Such as cement clinker, coal, coke, slag, slag, gypsum, clay, salt, chemical raw materials and other solid material equivalent to the above, with low maintenance costs, low power consumption, reliable performance, less dust, low noise Features. According to broken particle size requirements are: cone welding roller models, tooth roller models, flat roller models.

Product structure and principle:

Construction of the roller machine:

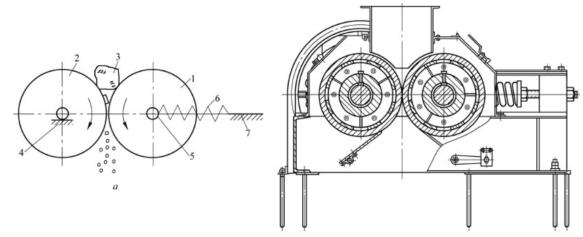

In terms of usage, most of the current use of twin-roll crusher. Structure made the following figure:

The roller crusher is mainly composed of roller assembly, roller bearing, compression and adjustment device and drive device and other components. Two rollers are respectively fixed on the two shafts, the shaft ends each have a set of bearing support, the fixed wheel is fixed on the frame with bolts, the activity wheel is equipped with safety spring and sliding bearing box. The movable wheel is used to adjust the gap, that is, the finished particle size or when the two rollers fall into the metal debris, the movable roller can be moved laterally so as not to damage the equipment.

The principle of roller crusher:

Two rounds of roller rotation, the ore into the two rollers, due to the role of friction, the ore was brought into the crushing space between the two rollers, squeezed and broken. Broken product under the action of self-weight, from the gap between the two rollers at the discharge, the minimum distance between the two rollers for the discharge port width, the maximum size of broken products that is decided.

1.2. Roller 3. Material 4. Fixed bearing 5. Movable bearing 6. Spring 7. Rack

The crushed material is dropped between the two rollers by the feed port, crushed and crushed, and the finished material naturally falls. In case of excessive or non-crushing material, the roller can be automatically retracted by the action of the hydraulic cylinder or spring, so that the roller gap increases, too hard or non-broken objects fall, so as to protect the machine from damage. Opposite the rotation of the two rollers have a certain gap, change the gap, you can control the maximum discharge size of the product. Double-roll crusher is the use of a pair of opposite rotation of the round roller, four-roll crusher is the use of two pairs of rotating round roller to reverse the operation.

The double roll crusher uses a triangular belt or universal joint coupling to drive and adjust the gap between the two rollers. Four-roll crusher with V-belt drive and adjust the gap between the rollers.

Product Application:

Can be widely used in cement, metallurgy, chemical, power, coal and other industries on the brittle and tough material processing.

Product specifications and technical parameters:

Types of | Serial number | Model specifications | Technical performance | Motor Power(KW) | Dimensions(mm) | weight(Kg) | ||

Feed particle size(mm) | Dispensing particle size(mm) | Production capacity(m3/h) | ||||||

双 | 1 | 2PG¢310×600 | <16 | 2~5 | 1.5~7 | 2×5.5 | 1750×2260×500 | 3600 |

2 | 2PG¢610×400 | <36 | 2~9 | 3~9 | 2×11 | 1785×2365×1415 | 3800 | |

3 | 2PG¢750×500 | <40 | 2~10 | 7~12 | 2×15 | 2720×2700×1400 | 10250 | |

4 | 2PG¢750×700 | <40 | 5~10 | 15~25 | 2×22 | 3422×2800×1705 | 11700 | |

5 | 2PG¢750×1000 | <40 | 2~10 | 6~30 | 2×30 | 4150×2800×1750 | 12500 | |

6 | 2PG¢900×500 | <40 | 2~10 | 9~30 | 2×22 | 2750×1790×2065 | 14000 | |

7 | 2PG¢900×900 | <40 | 2~10 | 11~45 | 2×30 | 2750×2180×2065 | 16800 | |

8 | 2PG¢900×1200 | <40 | 3~10 | 15~60 | 2×55 | 2750×2480×2065 | 20800 | |

9 | 2PG¢1000×800 | 25~90 | 3~40 | 12~50 | 2×45 | 2940×2080×2065 | 22600 | |

10 | 2PG¢1200×1000 | <40 | 3~12 | 10~50 | 2×37 | 3690×3430×2700 | 46820 | |

11 | 2PG¢1200×1200 | <40 | 3~12 | 18~68 | 2×75 | 3690×3630×2700 | 48600 | |

四 | 1 | 4PG750×500 | 30~60 | 2~10 | 3~10 | 18.5+17/11 | 2760×3585×2650 | 20800 |

2 | 4PG750×600 | 30~60 | 2~10 | 3.6~12 | 18.5+17/11 | 3390×2740×2650 | 21800 | |

3 | 4PG900×700 | 40~100 | 2~10 | 10~60 | 30+12/24 | 3150×4175×3147 | 28700 | |

4 | 4PG900×900 | 40~100 | 2~10 | 20~70 | 45+45/37 | 3150×4375×3147 | 31386 | |

5 | 4PG1200×500 | 50~120 | 3~10 | 30~90 | 75+55/40 | 9610×5600×4240 | 69000 | |