Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

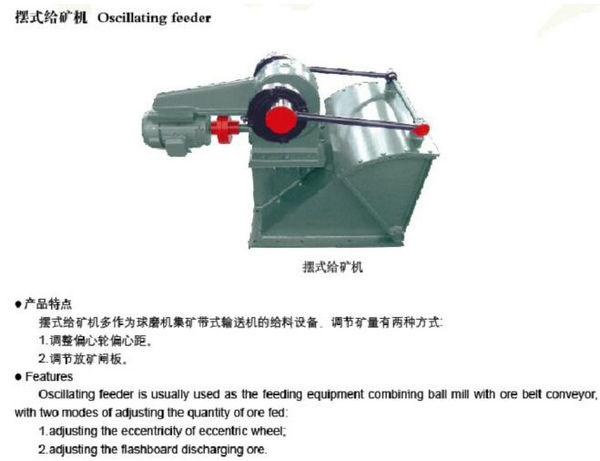

The pendulum is a mechanical device that achieves continuous and uniform feeding. It is installed in the bottom of a storage tank or funnel for conveying at a speed not exceeding 50 mm, dry and not easily agglomerated, such as ore, coal, etc. The But not suitable for the delivery of powder-like material, easy to produce clogging affect the feed, but also can cause powder flying and affect the workplace clean, the machine does not work can also be used as a lock. The machine due to the use of worm reducer, its structure is very compact size, and equipped with a reliable sealing device, not easy to make dirt into the internal impact of the work.

The vibration motor is the excitation source, the noise is low, the power consumption is small, the regulation performance is good, and the vibration is not stable. The vibration of the tilting machine is stable, the operation is reliable, the life is long; the excitation force can be adjusted and the flow rate can be changed and controlled at any time. Punching phenomenon. Simple structure, reliable operation, easy adjustment and installation, light weight, small size, easy maintenance, when the use of closed structure fuselage to prevent dust pollution.

Product structure and principle:

Adjustment method

1, use the method

(1) When the machine is screwed to the appropriate position under the hopper, the installation is completed.

(2) Before entering the work must check whether the worm gear reducer to add enough oil and the activities of the joints are filled with grease, found enough to fill the ministry should be enough oil.

(3) Before starting the motor without pulling the elastic coupling, observe the eccentric wheel connecting rod and jaw plate of the joint activities, such as the discovery of inflexible stuck, should try to eliminate it.

(4) When you complete the above steps, you can turn on the power to idle for 2-3 minutes, all the work is under normal circumstances, can enter the normal operation.

2, maintenance precautions

(1) should always pay attention to the wear parts of the activities of various parts of the situation.

(2) to always check the bearing reducer and other lubricants are missing. According to the actual use of the reducer in January to February for a lubricant.

(3) The machine is not allowed to operate the adjustment device during operation.

(4) When the machine fails or there is movement is not flexible when the first turn off the motor, after the exclusion of the parking.

(5) to always keep the machine inside and outside clean.

3, adjust the amount of feed method:

(1) change the position of the gate. First release the handle (8), the gate (7) can move up and down, change it with the jaw between the liner cross-section. This will control the amount of material passing through here. Tighten the handle (8) when the feed volume meets the requirements.

(2) adjust the eccentricity of the eccentric wheel. (See Figure 3) to loose the nut (4) turn the eccentric wheel (2) to change the eccentricity (d) size, according to the disc scale to determine the scale value of eccentricity is also large. The swing of the jaw also changes as the eccentricity changes. So that the volume of the material is also followed to change, you can achieve the needs of the number of needs, when the adjustment will be fixed after the fixed nut (4) tight.

The above two kinds can be adjusted to adjust the size of the supply, but the scope of regulation must be within the technical performance requirements to prevent overload and damage to the motor.

Product Application:

For the abrasive and other industries crushing, screening pendulum feeder in the production process, can be massive, granular material from the silo in the uniform, regular, continuous delivery to the receiving device, in the gravel production line In the metallurgical, coal, mineral processing, building materials, chemical, joint equipment, suitable for small pieces of material from the bulk of the bulk of the material, in particular, the material can be used for the continuous feeding of broken materials, Suitable for the ball mill to the ore and conveyor feeding, with a simple structure, cheap, easy operation and maintenance features, the machine for experimental plants, small and medium-sized concentrator for production operations.

Product specifications and technical parameters:

Specifications Model | Outlet size(mm) | Swing times (次/min) | Swing itinerary(mm) | Feed particle size(mm) | Yield(t/h) | Motor | ||

width | long | model | power(kw) | |||||

300x300 | 250 | 250 | 68 | 0-90 | 12 | 2-5 | Y90L-4 | 1.5 |

400x400 | 350 | 300 | 47 | 0-170 | 30 | 3-8 | Y100L1-4 | 2.2 |

600x600 | 550 | 400 | 45 | 0-220 | 50 | 7-12 | Y100L2-4 | 3 |

750x750 | 600 | 450 | 35 | 50-200 | 65 | 10-18 | Y112M-4 | 4 |