Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Trough feeder can be erected on the ground, can also be hoisted in the warehouse discharge port. The bottom plate for reciprocating motion, the rush for 20-60 times / min, stroke for the 20-200mm. The stroke can be adjusted appropriately by the drive eccentric, with the eccentricity being half of the stroke. According to some concentrator production practice, for viscous ore, eccentricity should not be less than 30mm. The slot width of the trough feeder is about 2-2.5 times the maximum particle size of the feedstock. The largest trough feeder can meet the ore size of less than 500mm grain ore. The most commonly used specification is the 980 * 1240 trough feeder, which gives a grain size of 350-0mm and is suitable for use as a 400 * 600 jaw crusher.

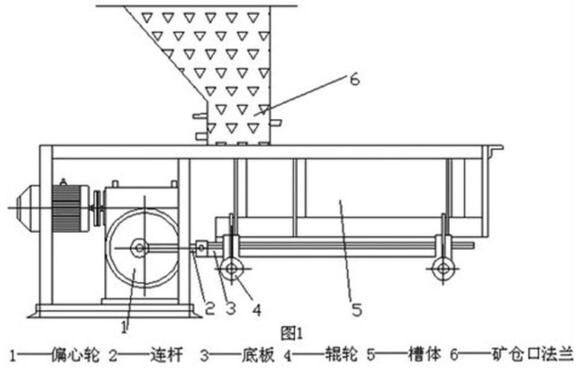

Product structure and principle:

Installation and maintenance of the machine:

Maintenance of the machine is an extremely important regular work, it should be with the operation of the machine and maintenance, etc., should be full-time staff on duty check.

Maintenance of the machine

1, the bearing bearing the full load of the machine, so good lubrication of the bearing life has a great relationship, it directly affects the machine life and operating rate, which requires the injection of lubricants must be clean, the seal must be good, the machine (1) Rotary bearings (2) Roller bearings (3) All gears (4) Movable bearings, sliding surfaces.

2, the new installation of the wheel prone to loose must be regularly checked.

3, pay attention to the work of the various parts of the machine is normal.

4, pay attention to check the wear parts of the wear and tear, pay attention to replace the wear parts.

5, put the activities of the chassis plane, should be out of dust and other objects in order to avoid the machine can not break the material when the activities of the bearings can not move on the chassis, resulting in serious accidents.

6, bearing oil temperature rise, should immediately stop the cause of the check to be eliminated.

7, rotating gear in the operation if the impact should immediately stop the inspection and eliminate

Install the test

1, the equipment should be installed on the basis of the level of concrete, with anchor bolts.

2, the installation should pay attention to the main body and horizontal vertical.

3, after installation, check the various parts of the bolt without loosening and whether the mainframe door fastening, if any fastening.

4, according to the power of the device configuration power lines and control switches.

5, check is completed, the empty load test, the test can be normal production.

Operation Rules for Trough Drainers

First, before the operation of the preparation and inspection

1, check the Department of fuel (grease) point is lack of oil.

2, the gear box lubricating oil is reached the oil line.

3, the Department of fastening bolts are loose phenomenon.

4, skateboards and roller care is tilted.

5, whether the loose pin of the phenomenon.

6, V-belt is damaged.

7, whether the tank body wear or other damage phenomenon.

8, safety devices such as belt cover is strong.

9, whether the ammeter pointer on the zero.

10, the Department of switches, buttons are intact.

Second, the operation method

1, driving method of operation

(1) before the operation must be checked by driving the contents of the check item by item.

(2) to hear the driving signal after the car ready to drive.

(3) Close the switch and start the operation button.

2, parking method

(1) Ore ore must be finished before stopping

(2) Press the button to stop the operation.

(3) Disconnect the power switch.

(1) without notice of power outages and emergency stop immediately pull the switch.

Product Application:

The tank type can be transported from the storage silo to the receiving device, widely used in metallurgy, mining, chemical, construction, mineral processing, coal and other departments as coarse grain materials (ore, etc.) Suitable for metal, non-metallic materials, short-distance transport, but not suitable for conveying concentrate powder and other powder materials.

Product specifications and technical parameters:

Model | Outlet (width x height) | Maximum particle size | The number of reciprocations at the bottom of the tank (per / Score) | Feeding capacity | power (kw) | Dimensions (L × W × H) | weight (kg) |

600×500 | 600×500 | 205 | 38.9 | 10-25 | 4 | 2750×910×855 | 1054 |

980×1240 | 980×1240 | 350 | 23.7 | 36-90 | 7.5 | 3560×1000×1070 | 1700 |

1000×1900 | 1000×1900 | 300 | 27 | 300 | 7.5 | 3900×1590×1340 | 2691 |