Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Electromagnetic vibration feeder is widely used in metallurgy, coal, electronics, machinery, chemical industry, building materials, light industry, food and other industries, in the production process, for the block, granular, powder material from the storage bin or The funnel is quantitatively, uniformly and continuously fed to the receiving device. Compared with other feeding equipment, has the following characteristics:

1. Electrical control using half-wave rectifier electrical appliances, can be adjusted to the infeed, can be used for automatic control of the production process, to achieve the production process automation.

2. No rotating parts, no lubrication, simple structure, easy maintenance.

3. The use of alloy steel plate made of trough, can be applied to transport high temperature, wear serious and corrosive materials.

Product structure and principle:

Electromagnetic Feeder Structure:

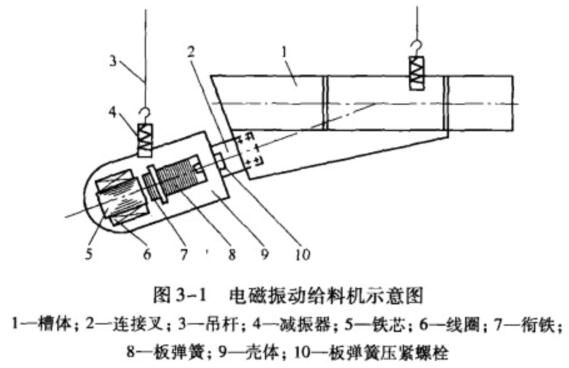

Electromagnetic vibration feeder generally consists of four main components (see Figure 3-1)

Electromagnetic Feeder works:

The current of the exciter electromagnetic coil is rectified by single-phase half-wave, and when the coil is connected, there is a current passing through the positive half-cycle, and a pulse electromagnetic force is attracted between the armature and the iron core. After the movement, the main spring of the exciter is deformed to store a certain potential energy. In the negative half-cycle coil, no current is passed, the electromagnetic force disappears, the main spring releases energy, so that the armature and the iron core move forward in the opposite direction from the tank body, So the electromagnetic vibration feeder to AC power frequency of 3000 times per minute reciprocating vibration, because the bottom of the tank body and the role of exciting force line has a certain angle, so the material in the tank along the parabolic trajectory continuous To move forward. Adjust the level of the rectifier voltage, you can control the electromagnetic vibration feeder feeding capacity. Feeder with SCR rectifier power supply. Change the thyristor conduction angle, you can control the level of the output voltage. According to the use of conditions, different signals can be used to control the size of thyristor conduction angle in order to achieve the purpose of automatic quantitative feeding.

installment and debugging

1, installation

(1) assembly must be fastened to the exciter and trough connection screw, so as not to affect the electromagnetic vibration of the feeder operation of the stability. In order to ensure the use of safety, electromagnetic vibration feeder on the grounding screw should be reliably grounded.

(2) This series of vibration motors are suspended installation with a solid and reliable wire rope or flower blue screw hanging on a sufficient amount of steel components, in order to reduce the vibration of the vibration of the groove, in the width of the suspension boom can be outward Open 10 ° arranged. A

(3) the installation can be tilted down the tank 10, if the use of electronic control device should be used in the horizontal installation, and check the horizontal level of the tank, or in the transport process, the material will be offset to one side.

(4) In order to reduce the pressure on the trough in the silo, it is necessary to install a chute with a certain inclination in the silo and the chute shall not touch the chute (see Figure 2)

(5) in the discharge port should be set gate gate width B must meet the following formula: A - 20> B> (2-3) d where: d - material maximum particle size (mm) A - Width (mm)

(6) after the installation of the vibration machine should have a certain around the swimming gap, so that the vibration in a free state.

(7) open slot vibration machine installation dimensions shown in Figure 3 and the table.

(8) closed slot vibration machine inlet and outlet can be installed dust bag, suitable for dustproof environment, the dimensions shown in Figure 4 and the table.

2, adjust

(1) adjustment of the air gap between the core and the armature according to the design requirements transferred to 2.8 ± 0.5mm, the product has been adjusted at the factory, can also be based on the use of units on the amplitude and feed requirements of different Appropriate to narrow or expand, but be careful not to excessive, if the air gap is too large will increase the current, burn the coil, on the contrary, if the air gap is too small, the core and the armature will be between the collision, resulting in iron , Armature and other components of the damage, air gap adjustment principle: a, to meet the requirements of amplitude. b, the current can not exceed the rated value (feeder no load) c, between the core and the armature shall not occur between the collision between the two parallel. (2) The vibration system of the tuned electromagnetic vibration feeder is designed to work in the low critical near-resonance state. Under the low critical near-resonance condition, the increase of the damping is often caused by the increase of the material and the silo pressure in the tank At the same time, the natural frequency of the vibration system becomes smaller and the tuning value W / W. It is closer to 1, so that the amplitude tends to increase, they compensate each other, so that the feeder can be more stable work, when the damping becomes smaller to maintain this mutual compensation relationship. I plant the main vibration of the main spring is a spiral spring, the steel is basically not adjustable, therefore, can only be used to change the quality of the way to adjust the tuning, in the exciter of the body with a few weight plate , With the increase or decrease the number of counterweight plate to change the quality of m2, from the formula that the quality of m will be changed to achieve the purpose of the developed natural frequency W0.

Use and maintenance

1, overtaking and maintenance of the initial start of the vibration machine, the controller should first switch to the manual position switch, the amount of power meter is small, connected to the power gradually increase the current until the rating, so as not to damage the regulator and Burn the coil, after normal use allowed in the rated voltage, current and amplitude directly under the start and stop.

2, test run electromagnetic vibration feeder production adjustment is usually used in the following two ways.

(1) adjust the amplitude of the vibration machine, within the rated amplitude range, by rotating the controller potentiometer knob or input automatic control signal can be directly adjust the amplitude, which can steplessly adjust the productivity of the vibrator. A

(2) adjust the size of the gate and the height of the bottom of the trough, change the thickness of the material layer, but also to achieve the purpose of regulating the production of vibration.

3, operation and maintenance

(1) at any time to check the various parts of the bolt is loose, and timely tightening.

(2) always pay attention to the ammeter pointer can not exceed the rated maximum.

(3) The air gap between the core and the armature must, in any case, be kept parallel and clean to ensure the stability of the work. For work in dusty areas or as ferromagnetic material, the shock absorber seal Cover close, operation, should pay attention to whether there is no impact between the core and the armature, such as hearing the impact, should immediately stop checking and re-adjust the air gap.

(4) during the operation of the equipment, such as sudden changes in vibration, such as noise suddenly become large, ammeter pointer irregular swing, etc., should immediately stop checking. a, check the fastener fastener fastening situation, for the main spring rod on the fastening nut to pay special attention to check the main spring, the main lead rod, etc. whether the phenomenon of fracture. If damaged, should replace the same specifications of the parts, check the exciter internal coil leads are open circuit. b, check the regulator whether there is a stable DC output voltage (available 220V300W bulb for load measurement) normal value of 0-85V continuously adjustable.

(5) Since one end of the thyristor is connected to the power supply input terminal. Therefore, in the maintenance, in addition to turn off the regulator switch, but also must cut off the input power, so that the machine completely out of power.

(6) If you want to turn off the exciter repair, it should be noted that the first four main spring series, in order to re-assembly in the original order and direction, re-assembled the exciter, must first under the rated parameters of power Test vibration, only in the maximum current does not exceed the rated value of the case, before re-installation in their work position.

(7) should be to avoid the winding lead and other lead wire bumps and rupture, in order to avoid short circuit and burn out the SCR.

Product Application:

GZ electromagnetic vibration feeder is a new type of feeding equipment, in cement, mining, metallurgy, coal, chemical, ceramics, food, electricity and other industrial and mining enterprises have been widely used, it is suitable for the block and powder materials Storage silo or funnel in a continuous or quantitative to the receiving device to the electronic scales or computer equipment and other equipment supporting the realization of the most ideal production automation equipment can also be a separate work feeding stability, without special care and with a variety of vibration Screen for the vibration of the ideal equipment.

Product specifications and technical parameters:

Types of | model | productivityt/h | Feed particle size(mm) | Double amplitude(mm) | Vibration frequency(min-1) | Supply voltage(V) | Current(A) | Active power(kw) | weight(kg) | ||

Level | -10° | Working current | Indicates current | ||||||||

Basic type | GZ1 | 5 | 7 | 50 | 1.75 | 3000 | 220 | 1.34 | 1 | 0.06 | 77 |

GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | 151 | ||||

GZ3 | 25 | 35 | 75 | 4.6 | 3.5 | 0.2 | 233 | ||||

GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | 460 | ||||

GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 668 | ||||

GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1271 | ||

GZ7 | 250 | 350 | 300 | 24.6 | 20 | 2.5 | 1920 | ||||

GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4.0 | 3040 | ||||

GZ9 | 600 | 840 | 500 | 47.6 | 38.6 | 5.5 | 3750 | ||||

GZ10 | 750 | 1050 | 500 | 39.4×2 | 32×2 | 4.0×2 | 6491 | ||||

GZ11 | 1000 | 1400 | 500 | 47.6×2 | 38.6×2 | 5.5×2 | 7680 | ||||

On the type of vibration | GZ3S | 25 | 35 | 75 | 1.75 | 220 | 4.6 | 3.8 | 0.20 | 242 | |

GZ4S | 50 | 70 | 100 | 8.4 | 7 | 0.45 | 457 | ||||

GZ5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 666 | ||||

GZ6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1246 | ||

GZ7S | 250 | 350 | 250 | 24.6 | 20 | 2.5 | 1963 | ||||

GZ8S | 400 | 560 | 300 | 39.4 | 32 | 4.0 | 3306 | ||||

Closed type | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1 | 0.06 | 78 | |

GZ2F | 8 | 11.2 | 40 | 3.0 | 2.3 | 0.15 | 154 | ||||

GZ3F | 20 | 28 | 60 | 4.6 | 3.8 | 0.20 | 247 | ||||

GZ4F | 40 | 50 | 60 | 8.4 | 7 | 0.45 | 464 | ||||

GZ5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | 668 | ||||

GZ6F | 120 | 168 | 80 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1278 | ||

Light groove type | GZ5Q | 100 | 140 | 200 | 1.75 | 220 | 12.7 | 10.6 | 0.65 | 653 | |

GZ6Q | 150 | 200 | 250 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1326 | ||

GZ7Q | 250 | 350 | 300 | 24.6 | 20 | 2.5 | 1992 | ||||

GZ8Q | 400 | 560 | 350 | 39.4 | 32 | 4.0 | 3046 | ||||

Flat groove type | GZ5P | 50 | 140 | 100 | 1.75 | 220 | 12.7 | 10.6 | 0.65 | 633 | |

GZ6P | 75 | 210 | 300 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1238 | ||

GZ7P | 125 | 350 | 350 | 24.6 | 20 | 2.5 | 1858 | ||||

Wide groove type | GZ5K1 | 200 | 100 | 1.5 | 220 | 12.7×2 | 10.6×2 | 0.65×2 | 1212 | ||

GZ5K2 | 240 | 100 | 12.7×2 | 10.6×2 | 0.65×2 | 1343 | |||||

GZ5K3 | 270 | 100 | 12.7×2 | 10.6×2 | 0.65×2 | 1376 | |||||

GZ5K4 | 300 | 100 | 12.7×2 | 10.6×2 | 0.65×2 | 1408 | |||||

1. Host selection:

Basic typeClosed typeWide groove type

Types of | Productivity calculation capacity(t/m3) | Use |

1.6 | No special requirements for material feeding | |

On the type of vibration | 1.6 | Configuration space is not enough to install the case, the other with the basic type of the same |

1.6 | Fragile particles, larger dust and volatile materials | |

Light groove type | 1.0 | Small proportion of light material feed |

Flat groove type | With coal conditions given | Thin material layer uniform feeding |

According to coal conditions given | Mainly used for coal preparation, can also be used to sieve equipment feeding |

When the actual bulk density is greater or less than the above calculated bulk density, the productivity is converted according to the actual material bulk density.

For materials with a particle size less than 1mm, the wetting viscosity of the material with a water content of more than 10% can not be transported normally. The thickness of the material layer is more than a de facto value, which will prevent the normal feeding. It is recommended that the thickness of the material layer H = (1/3 to 1/4)

For special requirements, special specifications of the products, our company can be specially designed and manufactured.

2. Supporting the control box

Supporting control box with manual control and automatic control of two functions. The automatic control signal is 0 ~ 5V or ~ 20mA. The basic circuit of the control box adopts the advanced phase-shifting trigger to control the solid-state relay as the original circuit rectification control original, the reliability is good and the life is long, is a new type of control circuit. Control box is divided into hanging and desktop two, please specify when ordering.