Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Traditional liquid pump for the conveyor belt particles, high viscosity, strong acid, alkali, salt, strong oxidants and other corrosive media. The new liquid pump is suitable for conveying a variety of lightweight media such as flammable and explosive. The traditional liquid pump its shell, outlet pipe and over-current parts are all made of corrosion-resistant materials, the motor part placed on the liquid surface, the pump part placed under the liquid surface, with strong corrosion resistance, no clogging, high temperature And so on. The new type of liquid pump its pump, motor and over-current components are all made of special materials, the motor part of the pump part of the coaxial connection placed under the surface, with maintenance-free, high explosion, zero use, low energy consumption Features.

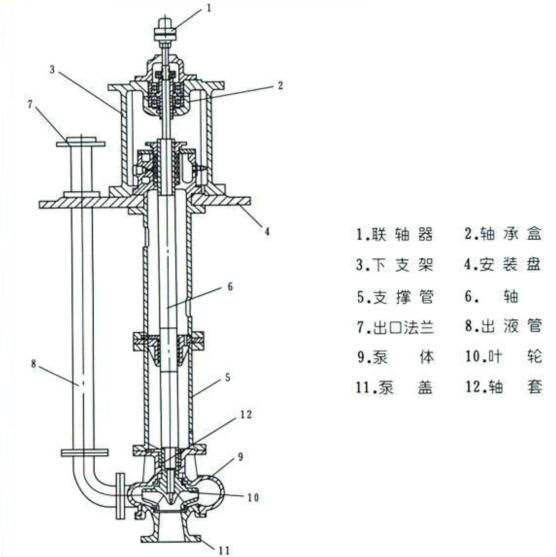

Product structure and principle:

According to the different needs of the length of the container into the container. Submerged pump motor part of the liquid surface, the pump part of the sun sinking in the liquid, so the shaft seal without liquid splash phenomenon; pump operation of the axial and radial forces, respectively, by the rolling bearing and sliding bearing support, the general temperature is high (300 degrees Above) the media bearing box parts at the cooling system, with cooling water to take away the heat.

Pumps and media contact parts, generally selected according to the requirements of the media, widely used in smelting, dyes, pesticides, pharmaceuticals, rare earth, fertilizer and other industries, in the tank to transport all kinds of media, open impeller can be used to transport solid Particle medium.

working principle:

The pump vertical motor to bolts the motor seat, and through the flexible coupling and pump direct drive, the pump, the middle of the tube, pump frame, the liquid pipe, pipe flange, bolted together to form a fixed, , The whole of the pump is mounted on the container through the floor.

Features:

1, the traditional liquid pump installed directly in the transport medium storage, no additional footprint.

2, the traditional liquid pump with a unique centrifugal double-balanced impeller for the delivery of solid particles and other clean media, low noise and high efficiency; the use of open double-balanced impeller for the transport is not clean with solid particles and Short fiber liquid, running smoothly, no clogging.

Assembly and disassembly

(1) Install the bearings on the bearing housing and the housing respectively.

(2) Felt the felt on the bearing end cap, C and the bearing housing.

(3) the bearing end cover B, mounted on the bearing seat and bolted.

(4) The bearing box bearing the bearing is worn on the shaft, screwed on the round nut, and the bearing end cap is fastened to the bearing housing.

(5) the shaft into the bearing, with bolts fixed, screw on the adjustment screw, and the bearing installed in the bearing seat, the retaining ring in the lower bearing at the appropriate location.

(6) Fix the coupling pipe to the bearing seat and install the pump cover in the lower part of the coupling pipe. Install the impeller on the lower part of the shaft and tighten it. Then install the pump front cover and fix the bolt, and use the adjustment screw Adjust the gap between the impeller and the front cover, (control in the 1 - 1.5mm) after adjusting with a nut, bolts fastening.

(7) motor support installed in the bearing seat with bolts fastening, the shaft at the top of the coupling components, and the motor coupling with fastening screws fastened to the motor shaft head, the motor installed in the motor support, And fastened with bolts and nuts.

(8) Install the asbestos pad, the eluent elbow, and the liquid pipe fitting from the order of the pump, and fix it on the support seat.

Start and stop

1, observe the pump installation base has been stable, all parts of the bolt is tightened.

2, start the motor, open the pressure gauge cocks, when the pump to the full number of work, adjust the valve opening to the required range.

3, the pump stops working, you should first stop the motor, and then close the pressure gauge cocks.

4, pump long-term operation, the pump should be open, wipe clean, coated with anti-rust oil properly preserved.

Running

1, pay attention to the pump bearing temperature, should not exceed the outside temperature of 35 degrees but the maximum should not be greater than 75 degrees.

2, the cup should be filled with calcium-based butter, to ensure that the bearings can be normal lubrication.

3, the pump in the first month of work, or after running 100 hours, should replace the motor support oil cups of butter, after each work 2000 hours after the replacement time.

4, regularly check the elastic coupling, pay attention to the motor bearing temperature rise.

5, moving through the process, such as the discovery of noise or unusual sound, should immediately stop checking.

6, the pump should be carried out every 2000 hours of periodic inspection, impeller, pump (or pump cover) between the friction can not be too large, the maximum gap can not exceed 1.5 mm, such as more than replaceable impeller or front cover.

7, pump work 6 hours, should check the machine seal, according to the degree of wear to be repaired or replaced, otherwise it will lead to damage to the pump shaft and bearing.

Product Application:

Widely used to absorb the Shahe, mud, ore field to send pulp, concentrates, tailings and drainage. Pump and medium contact parts, generally selected according to the requirements of the media,

Applicable media:

1. No media required for explosion protection;

2. medium temperature is higher;

3. A variety of acid and alkali salt corrosive media;

4. Conveyor belt of sewage, mud.

Product specifications and technical parameters:

model | Discharge diametermm | flowm3/h | Head liftm | Rotating speedr/min | powerKW | effectiveness% |

40YW12-15 | 40 | 12 | 15 | 2900 | 1.5 | 48 |

50YW20-7 | 50 | 20 | 7 | 1450 | 0.75 | 62 |

50YW10-10 | 〃 | 10 | 10 | 〃 | 0.75 | 54 |

50YW15-15 | 〃 | 15 | 15 | 2900 | 1.5 | 51 |

50YW15-20 | 〃 | 15 | 20 | 〃 | 2.2 | 51 |

50YW17-25 | 〃 | 17 | 25 | 〃 | 3 | 53 |

50YW25-32 | 〃 | 25 | 32 | 〃 | 5.5 | 49 |

65YW25-15 | 65 | 25 | 15 | 〃 | 2.2 | 52 |

65YW37-13 | 〃 | 37 | 13 | 〃 | 3 | 60 |

65YW25-28 | 〃 | 25 | 28 | 〃 | 4 | 58 |

80YW40-7 | 80 | 40 | 7 | 〃 | 2.2 | 50 |

80YW29-9 | 〃 | 29 | 9 | 〃 | 2.2 | 48 |

80YW43-13 | 〃 | 43 | 13 | 〃 | 3 | 65 |

80YW40-15 | 〃 | 40 | 15 | 〃 | 4 | 57 |

80YW50-25 | 〃 | 50 | 25 | 〃 | 7.5 | 56 |

100YW80-9 | 100 | 80 | 9 | 1450 | 4 | 62 |

100YW110-10 | 〃 | 110 | 10 | 〃 | 5.5 | 97 |

100YW65-15 | 〃 | 65 | 15 | 〃 | 5.5 | 59 |

100YW100-15 | 〃 | 100 | 15 | 〃 | 7.5 | 70 |

100YW80-20 | 〃 | 80 | 20 | 〃 | 7.5 | 71 |

100YW100-22 | 〃 | 100 | 22 | 〃 | 15 | 61 |

150YW145-9 | 150 | 145 | 9 | 〃 | 7.5 | 63 |

150YW200-10 | 〃 | 200 | 10 | 〃 | 15 | 64 |

150YW160-15 | 〃 | 160 | 15 | 〃 | 15 | 67 |

150YW180-22 | 〃 | 180 | 22 | 〃 | 18.5 | 74 |

150YW150-26 | 〃 | 150 | 26 | 〃 | 18.5 | 72 |

150YW130-30 | 〃 | 130 | 30 | 〃 | 22 | 69 |

150YW200-30 | 〃 | 200 | 30 | 〃 | 37 | 65 |

150YW150-35 | 〃 | 150 | 35 | 〃 | 37 | 63 |

200YW250-11 | 200 | 250 | 11 | 〃 | 15 | 72 |

200YW250-15 | 〃 | 250 | 15 | 〃 | 18.5 | 72 |

200YW400-10 | 〃 | 400 | 10 | 〃 | 22 | 75 |

200YW310-13 | 〃 | 310 | 13 | 〃 | 22 | 71 |

200YW400-13 | 〃 | 400 | 13 | 〃 | 30 | 76 |

200YW250-22 | 〃 | 250 | 22 | 〃 | 30 | 71 |

200YW350-25 | 〃 | 350 | 25 | 〃 | 37 | 73 |

200YW250-35 | 〃 | 〃 | 35 | 〃 | 45 | 69 |

250YW600-9 | 250 | 600 | 9 | 〃 | 30 | 78 |

250YW600-12 | 〃 | 600 | 12 | 〃 | 37 | 76 |

250YW600-15 | 〃 | 600 | 15 | 〃 | 45 | 73 |

The factory made of sand pump parts of the wear parts are selected high hard material manufacturing. With a long life, reliable performance, easy operation and so on.