Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Belt conveyor (belt conveyor), also known as tape conveyor, widely used in home appliances, electronics, electrical appliances, machinery, tobacco, injection, post and telecommunications, printing, food and other industries, objects assembly, testing, commissioning, packaging and transportation Wait. Line body can be selected according to the process requirements: ordinary continuous operation, beat operation, variable speed operation and other control methods; line body to local conditions: straight, corners, slopes and other linear body conveyor equipment, including: belt conveyor is also called belt Conveyor or tape conveyor, etc., is composed of rhythmic flow line indispensable economic logistics equipment. Belt conveyor according to its transport capacity can be divided into heavy belt conveyor such as mining belt conveyor, light belt machine such as used in electronic plastic, food industry, chemical and pharmaceutical industries. Belt conveyor with a strong transport capacity, transport distance, simple and easy to maintain, can easily implement the program control and automation operations. The use of conveyor belt continuous or intermittent movement to transport 100KG the following items or powder, granular objects, the operation of high-speed, smooth, low noise, and can be downhill transmission.

Product structure and principle:

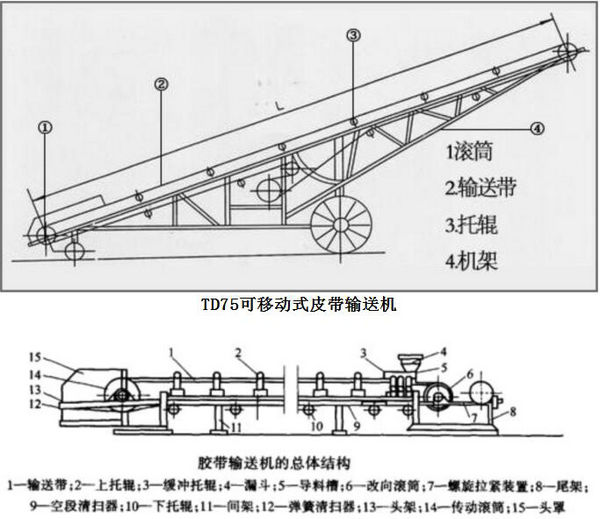

Belt conveyors are a friction-driven machine that continuously transports materials. Mainly by the rack, conveyor belt, roller, roller, tension device, transmission and other components. It can be material in a certain transmission line, from the initial feeding point to the final discharge point between the formation of a material transport process. It can be carried out fragile material delivery, can also be carried into pieces of goods delivery. In addition to pure material delivery, but also with the industrial production process in the process of matching the requirements of the formation of a rhythm of the pipeline operation of transport lines.

DT2 belt conveyor

Composition:

General belt conveyor by the conveyor belt, roller, roller and drive devices, brakes, tensioning device, loading, unloading, cleaning devices and other devices.

conveyor

Commonly used rubber belt and plastic belt with two kinds. Rubber belt for working environment temperature -15 ~ 40 ℃ between. Material temperature does not exceed 50 ℃, more than 50 ℃ when ordering to inform manufacturers, you can use high temperature conveyor belt. The inclination of the pellets is 12 ° to 24 °. For large dip conveyor belt available. Plastic belt with oil, acid, alkali and other advantages, but for the climate of poor adaptability, easy to slip and aging. Bandwidth is the main technical parameter of belt conveyor.

Roller

Slotted roller, flat idler, aligning roller, buffer roller. The grooved roller (consisting of 3 rollers) supports the bearing branch for conveying the particulate material; the aligning roller is used to adjust the lateral position of the belt to avoid deviation; the cushioning roller is mounted at the receiving material to reduce The impact of the material on the belt.

roller

Sub-drive roller and re-direction roller. Driving the drum is the main part of the transmission power. Separate drum (tape to drum of the package angle of 210 ° ~ 230 °), double drum (angle of 350 °) and multi-drum (for high power) and so on.

Tensioning device

Its role is to make the conveyor belt to the necessary tension, so as not to slip on the drive roller, and the conveyor belt between the roller to ensure that the deflection within the specified range. Including a screw tensioning device, a hammer tensioning device, a car tensioning device.

working principle:

The belt conveyor consists of two end-point rollers and a closed conveyor belt on it. The drum that drives the rotation of the conveyor belt is called the drive roller (drive roller); the other is only the drum that changes the direction of movement of the conveyor belt. The drive drum is driven by the motor through the gear unit, which is driven by the friction between the drive roller and the conveyor belt. Driving rollers are generally mounted on the discharge side to increase traction and facilitate dragging. The material is fed by the feed end and falls on the rotating conveyor belt, driven by the conveyor belt friction to the unloading end.

Belt Conveyor Features:

Belt Conveyor is the ideal high-efficiency continuous transportation equipment for coal mine. Compared with other transportation equipment (such as locomotive), it has the advantages of long transport distance, large transport capacity and continuous transportation. It is reliable and easy to realize automation and centralization. Control, especially for high-yielding and efficient mines, belt conveyors have become the key equipment for coal mining electromechanical integration technology and equipment. Belt conveyor is the main feature of the fuselage can be very easy to stretch, with a storage warehouse, the tail can be with the coal mining face to promote elongation or shortening, compact structure, can not set the foundation, The rack is light and easy to disassemble. When the transmission capacity and distance from the larger, can be equipped with intermediate drive to meet the requirements. According to the requirements of the conveyor process, you can stand alone, but also multi-unit synthesis level or tilt of the transport system to transport materials.

Technical advantages:

The first is that it runs reliably. In many important production units that require continuous operation, such as the transportation of coal in power plants, the transportation of bulk materials in steel mills and cement plants, and the use of belt conveyors in ships. If the downtime in these cases, the loss is huge. If necessary, the belt conveyor can work in a row to work continuously.

Belt conveyor has low power consumption. As the material and conveyor belt almost no relative movement, not only the running resistance is small (about scraper conveyor 1 / 3-1 / 5), but also on the cargo wear and fragmentation are small, high productivity. Which are conducive to reducing production costs.

The conveyor line of the belt conveyor is flexible and flexible. The length of the line depends on the need. Short a few meters, up to 10km or more. Can be installed in a small tunnel, can also be erected in the ground traffic chaos and dangerous areas over.

According to the requirements of the process, the belt conveyor is very flexible from one or more points by the material. It is also possible to discharge multiple points or sections. When feeding at a number of points to the conveyor belt at the same time (such as a conveyor under a coal seam in a coal preparation plant) or at any point in the longitudinal direction of the belt conveyor through a uniform feeding device, Machine to become a major transport trunk.

Belt conveyor can be in the coal storage pile under the pile of materials, if necessary, but also to the various layers of different materials for mixing. The material may simply be discharged from the head of the conveyor, or may be discharged at any point in the length of the conveyor belt by means of a plow unloader or a moving unloader.

Design Points:

1, working environment, status and conditions

Need to consider the time of operation every day, the frequency of work, belt conveyor life, feeding and discharge methods.

Working environment, condition: ambient temperature, open air or indoor, environmental requirements, mobile or fixed, telescopic requirements.

2, the transmission line and conveyor belt problems

Need to consider in detail the size of the transmission line, including: inclination, the maximum length, lift height; straight line, the size of the curve segment; connection size.

Conveyor belt: maximum sag demand, simulated frictional resistance coefficient, coefficient of friction, safety factor.

3, the nature of the material and the amount of delivery

Need to consider the specific properties of the material, including: loose density, the angle of repose, the particle size of the material, the maximum degree of the situation, the material humidity, material wear, adhesion and friction coefficient. The amount of delivery, the flow can be directly reached when the amount of uniform delivery, the material flow can be considered uneven when the material flow to the basic statistical data.

Safe operation:

Belt conveyor has become one of the important equipment in the whole production. Advanced structure, strong adaptability, low resistance, long life, easy maintenance, complete protection device is a belt conveyor significant features.

Before the operation of the belt conveyor, first of all to confirm the belt conveyor equipment, personnel, the items are transported in a safe and intact state; second check the normal parts of the movement without foreign matter, check all electrical lines are normal, normal to the belt The conveyor is put into operation. And finally to check the supply voltage and equipment rated voltage difference of not more than ± 5%.

Run operation:

1. Turn on the main power switch, check that the power supply is normal and the power indicator is on. Normal after the next step.

2. Close the power switch of each circuit to check whether it is normal. In normal state, the device does not operate, the belt conveyor running indicator does not light, the inverter and other equipment power indicator light, the inverter display panel shows normal (no fault code display).

3. Start the electrical equipment according to the process, and then start the next electrical equipment after the electrical equipment has started normally (the motor or other equipment has reached the normal speed and the normal state).

In the operation of the belt conveyor, must comply with the provisions of the items to be transported items, to comply with the design of belt conveyor capacity. Second, we should pay attention to all kinds of personnel shall not touch the belt conveyor part of the movement, non-professionals are not free access to electrical components, control buttons and so on. Finally, in the belt conveyor can not run on the inverter after the end of the circuit, such as the need to determine the maintenance, you must stop the frequency of the case to run, otherwise it may damage the inverter.

Belt conveyor running stop, press the stop button to stop all the system before you can cut off the total power.

Model selection:

⑴ the weight of the delivery of objects (including the weight of the spreader), the size and its hanging way;

⑵ line length and its complexity, that is, horizontal rotation and vertical bending section of the number;

(3) the working conditions and working frequency of the conveyor;

⑷ conveyor speed and productivity;

⑸ special process requirements.

The power roller table consists of a power roller barrel assembly, an aluminum side plate, a chip holder, a rod, a seat, a drive device and a chain. The powerless roller table consists of a non-powered roller assembly, an aluminum side plate, a frame, a drawbar, and a seat. The power roller table drives the traction chain by the drive device, and the chain drives the sprocket wheel on each power roller to rotate, thereby operating by the rotation. The non-powered roller presses the workpiece by pushing the workpiece or the workpiece and moving it on a free roll.

Installation and commissioning:

To commission the belt conveyor:

⑴ equipment after installation carefully commissioned belt conveyor to meet the pattern requirements.

⑵ the reducer, moving parts filled with the corresponding lubricants.

⑶ install the belt conveyor to meet the requirements of a single device after the manual test, and combined to adjust the belt conveyor to meet the requirements of the action.

⑷ commissioned the electrical parts of the belt conveyor. Including the regulation of conventional electrical wiring and action, the equipment has good performance, to achieve the design function and status.

Common malfunctions:

Belt deviation

To address this type of failure, pay attention to the dimensional accuracy of the installation and the daily maintenance. There are a variety of reasons for deviation, need to be dealt with according to different reasons.

1. Adjust the belt of the belt conveyor belt to adjust the position of the roller group to adjust the deviation when the middle of the belt conveyor is in the middle; the mounting holes on both sides of the roller group are made into long holes at the time of manufacture so that To make adjustments. The specific method is to adjust the side of the belt, which side of the roller group to move forward in the direction of the belt forward, or the other side of the back.

2. Install the aligning roller set. There are many types of aligning roller sets, such as intermediate shaft type, four-link type, vertical roller, etc. The principle is to use the block or roller in the horizontal direction of the rotation of the block or produce horizontal thrust to automatically adjust the belt to adjust the belt to run Partial purpose. It is generally reasonable to use this method when the overall length of the belt conveyor is shorter or when the belt conveyor is bi-directionally operated because the shorter belt conveyor is easier to deviate and is not easy to adjust. The long belt conveyor is best not to use this method, because the use of aligning roller group will have a certain impact on the life of the belt.

3. Adjust the drive roller and change the drum position. Driving the drum and the adjustment of the drum is an important part of the belt deviation adjustment. Because a belt conveyor has at least 2 to 5 rollers, all drums must be mounted at a position perpendicular to the centerline of the belt conveyor. If the skew is too large, the deviation will occur. The adjustment method is similar to adjusting the roller group. For the head roller, such as the belt to the right side of the drum deviation, the right side of the bearing seat should move forward, the belt to the left side of the roller deviation, the left side of the bearing seat should move forward, the corresponding also Move the left side bearing seat back or the right side bearing seat backwards. The tail roller is adjusted in the opposite direction to the head roller. Adjustment method. After repeated adjustments until the belt transferred to the ideal location. It is advisable to install the position correctly before adjusting or reversing the drum.

4. Adjustment of tension. The adjustment of the belt tension is a very important part of the belt conveyor deviation adjustment. The two counter-rollers in the upper part of the hammer tension should be perpendicular to the gravitational perpendicular to the longitudinal direction of the belt, ie to ensure that the centerline of the shaft is horizontal. When tensioning with a screw tension or hydraulic cylinder, the two bearing housings of the tension roller should be translated at the same time to ensure that the roller axis is perpendicular to the longitudinal direction of the belt. The adjustment of the specific belt deviation is similar to that of the roller.

5. Transfer point at the blanking position on the belt deviation of the impact. The blanking position of the material at the transfer point has a very large effect on the deviation of the belt, especially when the two belts are projected vertically in the horizontal plane. Usually should consider the transfer point at the upper and lower two belt machine relative height. The lower the relative height, the greater the horizontal velocity component of the material, the greater the lateral impact on the lower belt, and the material is also difficult to center. So that the material in the belt cross section on the skew, eventually leading to the belt deviation. If the material to the right side, the belt to the left side deviation, and vice versa. In the design process should be as much as possible to increase the relative height of the two belt machine. In the space-limited movement of bulk transport machinery up and down funnel, guide trough and other pieces of the form and size should be carefully considered. The width of the general guide groove should be about two thirds of the width of the belt. To reduce or avoid the belt deviation can increase the block material to block the material, change the direction and location of the material falling.

6. Bidirectional operation Belt conveyor deviation adjustment. Two-way operation of the belt conveyor belt deviation adjustment than the one-way belt conveyor deviation adjustment is much more difficult, in the specific adjustment should first adjust a direction, and then adjust the other direction. Adjust the time to carefully observe the belt movement and the trend of deviation, one by one to adjust. The focus should be on the adjustment of the drive roller and the reeling drum, followed by the adjustment of the roller and the adjustment of the blanking point of the material. At the same time should pay attention to the belt in the vulcanization joints should be the length of the direction of the belt section of the force evenly, in the use of guide chain when the two sides of the force as much as possible equal.

Sprinkle treatment

Belt conveyor is a common problem, the reasons are many. But the focus is to strengthen the daily maintenance and maintenance.

1. At the transfer point of the spices at the transfer point of the sprinkler is mainly in the hopper, guide trough, etc.. Such as belt conveyor serious overload, belt conveyor guide trough block rubber skirt damage, guide groove at the design of the steel from the belt far more rubber skirt longer material to the material out of the trough. The above situation can be in the control of transport capacity, strengthen the maintenance to be resolved.

2. When the concave radius of the belt is small, the belt will be vacant when the radius of curvature of the concave section is small. At this time, the belt becomes a change of the groove, because the belt has left the groove roller group, the general groove angle So that part of the material spilled out. Therefore, in the design phase should be used as much as possible a large radius of curvature to avoid such a situation. Such as in the mobile mechanical loading machine, heap reclaimer equipment in order to shorten the tail car and the concave section of this design into a non-circular transition interval, when the belt width is relatively easy to use when the smaller amount of scavenging material.

3. Spreading when the deviation of the sprinkling of the belt is because the belt in the run when the two edge height changes, while high, while the other low, the material from the low side of the sprinkled, the method is to adjust Belt deviation.

Belt Conveyor Installation:

Before installation:

Transfer the tower and the silo after the end of the belt machine installation.

Precautions:

All belt machines are installed and adjusted in accordance with geological parameters and drawings.

Installation work:

Crossed

Check the civil construction, see the anchor bolts and embedded steel plate situation

Check the location of the various parts of the belt machine

Install the truss according to the anchor bolts

Installation and adjustment of equipment (including upper and lower rollers, wipers, drive, etc.)

Install the tape hoist

Install the telescopic head

Install the guide trough

Install the tensioning device

Install all electrical parts of the bracket

Tape cutting and vulcanization connection

The work before the end of the installation

an examination:

Check that the belt machine is consistent with the drawings and geometric graphic parameters before installing the tape.

Electrical parts:

Install the cable duct

Installation limit switches, protection devices, electric control cabinet and so on

Installation lighting

Laying cables

Connect the wires

Paint:

Clean the damaged parts of the paint and apply the paint to the paint according to the technical specifications.

lubricating oil:

Apply grease or lubricating oil to the following equipment as specified in the Lubricant Operating Manual: reducer, coupler, crane, bearing, motor bearing, etc.

Product Application:

Tape conveyor, also known as belt conveyor, conveyor belt according to the principle of friction and movement, suitable for conveying bulk density less than 1.67 / ton / cubic meter, easy to extract the powder, granular, small pieces of low-cut materials and Bags, such as coal, gravel, sand, cement, fertilizer, food and so on. Tape conveyor can be used in the ambient temperature range of -20 ℃ to +40 ℃, sent to the material temperature is less than 60 ℃. The captain and assembly form can be determined according to user requirements, the drive can be used drum, can also be used with drive frame drive device.

Can be used for horizontal transport or tilt transport, the use of very convenient, widely used in a variety of modern industrial enterprises

Tape width(mm) | Conveying length(m)/power(kw) | Conveying speed(m/s) | Delivery quantity(t/h) | ||

500 | ≤12/3 | 12-20/4-5.5 | 20-30/5.5-7.5 | 1.3-1.6 | 60-150 |

650 | ≤12/4 | 12-20/5.5 | 20-30/7.5-11 | 1.3-1.6 | 130-320 |

800 | ≤6/4 | 6-15/5.5 | 15-30/7.5-15 | 1.3-1.6 | 280-540 |

1000 | ≤10/5.5 | 10-20/7.5-11 | 20-40/11-22 | 1.3-2.0 | 430-850 |

1200 | ≤10/7.5 | 10-20/11 | 20-40/15-30 | 1.3-2.0 | 655-1280 |

说明:

1、表中输送量是在物料密度为1.0t/m3-1.6t/m3,输送机倾角≤18°,物料堆积角为30° 的条件下得出。

2、可输送物料密度在2.5t/m2以下。

3、输送长度不局限于表中所列值,可根据用户的需要进行制造。