Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Hydrocyclone

Product Overview:

The hydrocyclone is a device for the separation and removal of heavy coarse sediment and other substances in the effluent. Sometimes used for mud dewatering. Sub-pressure and gravity of the two, often using a circular column structure or metal pipe production. The water is fed by the upper part of the structure (or metal pipe) along the tangential force, and under the centrifugal force, the coarse particulate matter is discharged to the wall of the vessel and rotated down and drained together with the formed dope. The smaller particles of material rotation to a certain extent, although the second vortex discharge.

Product structure and principle:

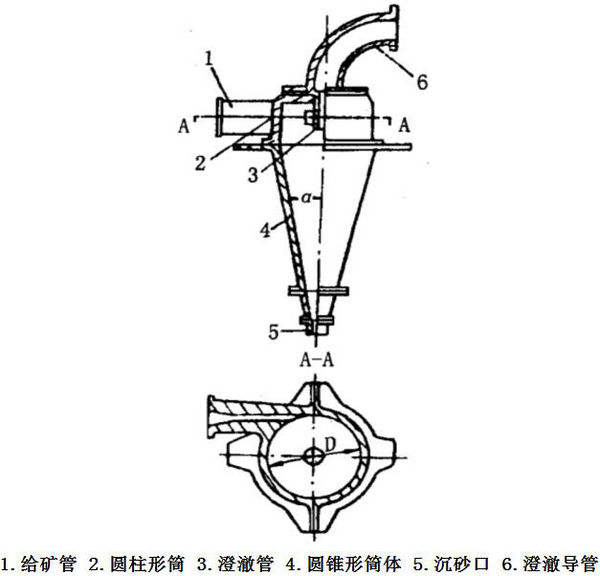

Hydrocyclone construction: the upper part is conical. A cylindrical tube is provided with a feed pipe which is tangential to the tube wall. The upper part of the cone is provided with a central overflow pipe communicating with the cylindrical part. The upper end of the overflow pipe is connected to the external pipe through the buffer chamber or directly to discharge the overflow. In the conical bottom with a sinker to discharge coarse particles of sand. In order to reduce the wear and tear, can be in the mine mouth, sand and the cylinder lining the inner lining of wear-resistant rubber or with diabase, cast stone, silicon carbide and other wear-resistant materials.

Hydrocyclone works:

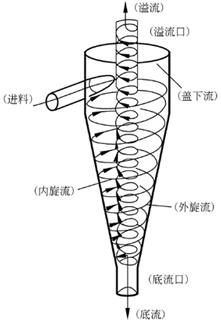

When the slurry with a sand pump (or height difference) to a certain pressure (usually 0.5 ~ 2.5 kg / cm) and flow rate (about 5 ~ 12 m / s) to the ore pipe along the tangential direction into the cylinder, the pulp will be very Fast speed along the cylinder wall rotation, and produce a great centrifugal force. Under the action of centrifugal force and gravity, the thicker and heavier mineral particles are directed towards the wall of the vessel, moving down the trajectory along the helix and discharged from the row of quarrels, The center of the cone and the water form an internal spiral of the rising pulp stream, which is discharged through the overflow pipe.

Hydrocyclone compared with the mechanical classifier, its advantages are:

1. Light and flexible, no moving parts, simple structure;

2. Low cost of equipment, easy assembly and disassembly, easy maintenance, small footprint, less infrastructure costs.

3. Unit capacity of the larger capacity;

4. Fine grading fine, up to 10 microns;

5. High classification efficiency (up to 80% to 90%);

6. Low cost, less material consumption.

7. Pulp in the cyclone in the amount of time and time, downtime is easy to handle.

The downside is:

1. To the mine sand pump power consumption and wear fast, the unit power consumption is about several times the spiral classifier, but the classification efficiency can make up for this loss.

2. Machine wear and tear fast, mainly to the mouth of the mouth of the grinding mouth wear fast, so lined with rubber and polyurethane and other wear parts and easy to replace, and some size of the mouth can be adjusted.

3. To the ore concentration, particle size, viscosity and pressure of small fluctuations that work indicators have a great impact, for which the corresponding automatic control device can be configured.

Product Application:

Hydrocyclones have been widely used in the mineral processing of major metal mines. Mainly in the following operations:

1, a closed-circuit grinding grading

2, two closed-circuit grinding grading

3, concentrate re-grinding grading

4, the original election before the election mud

5, tailings of the dam and backfill

In the closed-circuit grinding and grading system composed of a grinding mill, the grading efficiency is higher than that of the conventional spiral classifier with higher grading efficiency and finer fineness at higher ore concentration. 10%, is conducive to the improvement of the utilization factor of the mill.

According to the requirements of grinding capacity, overflow fineness and grit concentration, it is a prerequisite for the optimal selection of the appropriate specifications and model cyclone. Tongge company can provide users with Φ50, Φ75, Φ100, Φ125, Φ150, Φ200, Φ250, Φ300, Φ350, Φ500, Φ660 and other stand-alone, parallel unit or series unit.

In the beneficiation tailings sent to the tailings treatment, tailings less than 37μm fine sand should not be used as tailings dam material. After the classification of the cyclone, the coarse-grained tailings remain in the dam site, the fine-grained to the tailings of the tailings, the fine-grained pulp is naturally graded during the flow, and the dilute and fine tailings are naturally Grading, in the tail of the tail of the tail there is a clear water area, can be used as backwater. Full-tail filling process, the use of cyclone pre-graded concentration, so that most of the coarse particles in advance separation, reduce the follow-up filter load, to achieve better results. The use of cyclone to complete the dam and filling operations, can solve the tailings dam dam leakage, beach collapse, excessive drainage and other issues, can achieve significant economic and social benefits.

Product specifications and technical parameters:

specification | Cylinder diameter(mm) | Cone angle(度) | Overflow pipe straight(mm) | Bottom flow straight(mm) | Allow maximum particle size(mm) | Feed pressure(Mpa) | Processing capacity | Grading(um) | Dimensions | Stand-alone weight(Kg) | ||

long(mm) | width(mm) | long(mm) | ||||||||||

FX660 | 660 | 20 | 180~240 | 80~150 | 16 | 0.03-0.2 | 250~350 | 74-220 | 1140 | 1110 | 2635 | 990 |

FX610 | 610 | 20 | 170~220 | 75~120 | 13 | 0.03~0.2 | 200~300 | 74~220 | 1075 | 1030 | 2250 | 830 |

FX500 | 500 | 20 | 130~200 | 35~100 | 10 | 0.03~0.3 | 140~220 | 74~200 | 895 | 830 | 2050 | 495 |

15 | 74~150 | 895 | 830 | 2380 | 540 | |||||||

FX350 | 350 | 20 | 80~120 | 30~70 | 6 | 0.04~0.3 | 60~100 | 50~150 | 775 | 605 | 1765 | 220 |

15 | 50~120 | 775 | 605 | 2115 | 235 | |||||||

FX300 | 300 | 20 | 65~115 | 20~50 | 5 | 0.04~0.3 | 45~85 | 50~150 | 550 | 480 | 1415 | 108 |

15 | 40~100 | 550 | 480 | 1670 | 169 | |||||||

FX250 | 250 | 20 | 60~100 | 16~45 | 3 | 0.06~0.35 | 40~60 | 40~100 | 490 | 415 | 1215 | 79 |

15 | 40~100 | 490 | 415 | 1430 | 84 | |||||||

10 | 30~100 | 490 | 415 | 1850 | 92 | |||||||

FX200 | 200 | 20 | 40~65 | 16~32 | 2 | 0.06~0.35 | 25~40 | 40~100 | 400 | 365 | 1030 | 54 |

15 | 30~100 | 400 | 365 | 1200 | 59 | |||||||

10 | 30~100 | 400 | 365 | 1530 | 66 | |||||||

FX150 | 150 | 20 | 30~45 | 8~22 | 1.5 | 0.06~0.35 | 11~20 | 30~74 | 310 | 310 | 820 | 32 |

15 | 30~74 | 310 | 310 | 920 | 36 | |||||||

8 | 30~74 | 310 | 310 | 1400 | 42 | |||||||

FX125 | 125 | 17 | 25~40 | 8~18 | 1 | 0.06~0.35 | 8~15 | 20~100 | 210 | 185 | 620 | 10 |

8 | 20~74 | 250 | 240 | 985 | 12 | |||||||

FX100 | 100 | 20 | 20~40 | 8~18 | 1 | 0.06~0.35 | 5~12 | 20~100 | 260 | 210 | 525 | 8 |

15 | 20~100 | 268 | 215 | 720 | 13 | |||||||

8 | 20~100 | 268 | 215 | 1045 | 30 | |||||||

FX75 | 75 | 15 | 15~22 | 6~12 | 0.6 | 0.1~0.4 | 2~5 | 20~74 | 240 | 230 | 465 | 4.2 |

6 | 5~40 | 240 | 230 | 800 | 7 | |||||||

FX50 | 50 | 15 | 11~16 | 3~8 | 0.3 | 0.1~0.4 | 1~2 | 10~74 | 160 | 155 | 350 | 2 |

6 | 5~30 | 160 | 155 | 590 | 2.5 | |||||||