Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

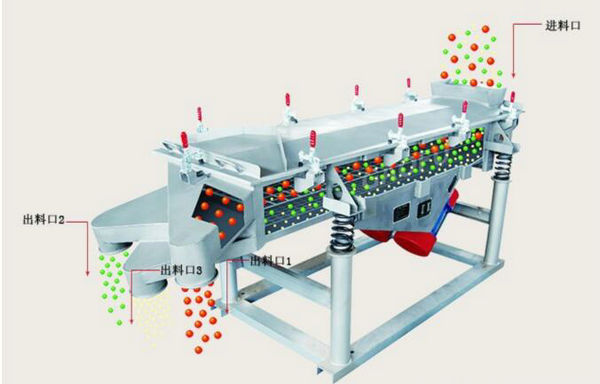

ZXS series of linear vibrating screen is a double vibration motor drive. When the two vibration motor to do synchronization, anti-pot rotation, the eccentric block generated by the exciting force in the direction parallel to the motor axis offset each other in the direction perpendicular to the motor shaft stacked together, so the sieve machine movement trajectory For a straight line. The two motor shafts have an inclination angle with respect to the sieve surface. Under the combined action of the exciting force and the material gravity, the material is jumped forward on the screen surface to make the forward movement, so as to achieve the purpose of screening and grading the material.

Linear vibrating screen is the use of vibration motor vibration as a vibration source, so that the material is sung on the screen, while moving forward straight, the material from the feeder evenly into the sieve inlet, through the multi-layer screen to produce the number The specifications of the sieve material, sieve, respectively, from their respective exports. With low energy consumption, high yield, simple structure, easy maintenance, fully enclosed structure, no dust, automatic nesting, more suitable for assembly line operations.

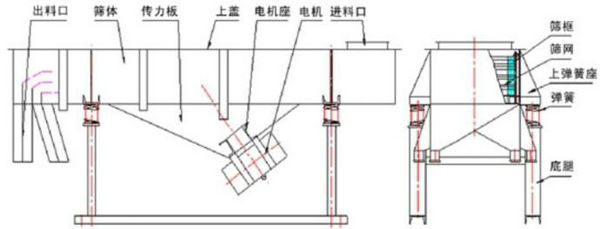

Product structure and principle:

Linear vibrating screen consists of vibration motor, screen box, screen, vibration body, vibration damping device.

1, screen box: from a few different thickness of the plate made of steel, with a certain strength and stiffness, is the main part of the screen machine.

2, the grid: from a few different thickness of the plate made of welding, used to keep the screen flat tension, to achieve normal screening. If the proportion of large or large output can be used when the metal screen box.

3, the screen: in line with national standards of stainless steel mesh.

4, vibration motor use and maintenance methods see vibration motor instructions.

5, the motor pedestal: the standard type (the motor installed in the sieve box below) sieve machine motor table can be moved, the use of the front screw must be tightened, especially the new sieve machine trial must be repeated three days before, ACCIDENT.

6, vibration spring: to prevent vibration to the ground while supporting the full weight of the screen box. When installed, the spring must be perpendicular to the ground.

7, bracket: composed of channel, supporting the main shaker. Installation pillars must be perpendicular to the ground, the two pillars below the tank should be parallel to each other.

Working principle: When the two vertical mounted on the sieve body relative rotation, the vibrating motor at both ends of the eccentric block will produce the rated exciting force, which produces in the lateral excitation force cancel each other, the longitudinal excitation force Through the sensor body to the entire screen surface, so that the material on the screen surface by its exciting force to the direction of the material to jump the direction of straight movement, less than the sieve material fell to the lower, out of the mouth out, After the vibrating screen is graded, the screening process is rationalized by reasonable matching screen, and several kinds of materials with different grain sizes are obtained to complete the screening of the whole material. Applicable to the particle size of 0.074-5mm, water content of less than 70%, non-sticky variety of dry powder material screening, the maximum feed size is not greater than 10mm.

Linear vibrating screen Main features:

First, the classification of linear vibrating screen on a variety of materials for grading screening, the size of the particles after screening uniform, high precision screening.

Second, the classification of linear vibrating screen is generally designed for a single 1-5 layer, according to the different needs of the required number of layers.

Third, the classification of linear vibrating screen with easy maintenance, maintenance probability is relatively low advantage.

Fourth, the use of linear screen angle adjustable excitation source, the net screen; can be multi-layer design, sieve and more; negative pressure evacuated, the environment is good. The linear vibrating screen has the characteristics of high precision, large amount of treatment, simple structure, low energy consumption, low cost, low noise, long service life of screen, good sealing, very few dust and easy maintenance. The product is widely used in chemical, food, plastics, pharmaceutical, metallurgy, glass, refractory, food, fertilizer, abrasive, ceramics and other industries in the dry powder or granular material classification or screening operations. It can be used in pipelining operations to automate.

Product Application:

It is widely used in plastics, abrasive, chemical, pharmaceutical, building materials, grain, carbon, fertilizer and other industries. Applicable to the particle size of 0.074-5mm, water content of less than 70%, non-sticky variety of dry powder material screening. Maximum particle size of not more than 10mm.

On the powder, granular materials, screening and classification, has a unique effect. Widely used in chemical, pharmaceutical, food, metal, metallurgical and mining industries.

Chemical industry: fertilizer, urea, petroleum coke, resin, paint, cosmetics, paint and so on.

Pharmaceutical industry: industrial medicine, Chinese medicine powder, granules pills, pellets and so on;

Food industry: soybeans, chestnut, small bread, spices, sugar powder, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice and so on.

Metal, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, Calcium, quartz sand, metal powder industry, mining industry and so on.

Other industries: plastic, abrasive, waste oil, waste water, dyeing and finishing wastewater, paper, additives, activated carbon, carbon, building materials industry.

Linear vibrating screens are general purpose equipment, depending on the industry, the implementation of different standards, such as: food grade, pharmaceutical grade, can be tailored.

Product specifications and technical parameters:

model | 筛面尺寸 (mm) | Number of surface layers | Mesh size(Purpose/m) | Processing capacity(t/h) | Vibration time (r.p.m) | Double amplitude(mm) | Motor Power(Kw) | Motor Power | Dimensions (Length × width × height) (mm) |

1-520 | 500×2000 | 1 | 2-200 | 0.05-5 | 960 | 6-7 | 2×0.4 | 45-60 | 2140×808×848 |

2-520 | 0.05-5 | 960 | 6-7 | 2×0.4 | 45-60 | 2199×808×878 | |||

3-520 | 500×2500 | 0.03-5 | 1450 | 4-6 | 2×0.4 | 45 | 2256×808×938 | ||

1-525 | 0.06-8 | 960 | 5-7 | 2×0.4 | 45-60 | 2642×808×848 | |||

2-525 | 0.06-8 | 1450 | 4-6 | 2×0.4 | 45 | 2699×808×878 | |||

3-525 | 0.06-8 | 960 | 6-8 | 2×0.75 | 45-60 | 2750×808×938 | |||

4-525 | 0.1-15 | 1450 | 5-7 | 2×0.4 | 45 | 2813×808×1000 | |||

5-525 | 0.08-15 | 1450 | 5-7 | 2×0.4 | 45 | 2883×808×1060 | |||

6-525 | 0.07-15 | 960 | 6-8 | 2×0.75 | 45-60 | 2953×808×1120 | |||

1-1020 | 1000×2000 | 1 | 0.12-20 | 960 | 6-8 | 2×0.75 | 45-60 | 2152×1320×900 | |

2-1020 | 2 | 0.11-20 | 960 | 5-7 | 2×0.75 | 45-60 | 2219×1320×960 | ||

3-1020 | 1000×2000 | 3 | 2-200 | 0.10-20 | 960 | 5-7 | 2×0.75 | 45-60 | 2286×1320×1030 |

4-1020 | 4 | 0.07-15 | 960 | 4-8 | 2×0.75 | 45-60 | 2353×1320×1100 | ||

5-1020 | 5 | 0.07-15 | 960 | 4-8 | 2×1.5 | 45-60 | 2420×1320×1160 | ||

6-1020 | 6 | 0.07-15 | 960 | 4-8 | 2×1.5 | 45-60 | 2487×1320×1220 |