Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

SF flotation machine for the separation of non-ferrous metals, ferrous metals, precious metals, non-metallic minerals and chemical raw materials, recovery of useful minerals. The device has the following characteristics: large suction, low power consumption. Each tank with both suction, suction and flotation triple function, since the flotation circuit, without any auxiliary equipment, the level of configuration, easy to change the process of pulp pulp reasonable, to minimize the coarse sand precipitation. Equipped with pulp surface of the automatic control device, easy to adjust. Impeller with a backwards and down the leaves. The upper leaves produce the slurry on the circulation, the lower leaves produce the pulp under the circulation.

Product structure and principle:

Flotation machine is mainly used for sorting copper, zinc, lead, nickel, gold and other non-ferrous metals, can also be used for ferrous and non-metallic rough selection and selection. The engine is driven by the motor V-belt drive to rotate the impeller, resulting in centrifugal action to form a negative pressure. On the one hand, the suction air is mixed with the pulp. On the one hand, the mixing pulp is mixed with the drug, and the foam is refined to make the mineral stick To the slurry surface to form a mineralized foam. Adjust the height of the gate, control the liquid surface, so that useful foam scraped by the scraper.

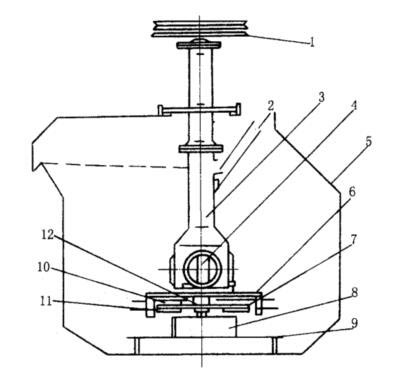

1. Pulley 2. Suction pipe 3. Center tube 4. Spindle 5. Trough 6. Cover plate 7. impeller

8. Guide tube 9. False 10. On the leaves 11. Under the leaves 12. Impeller

SF-type flotation machine with "U" -type tank, hollow shaft inflatable and suspension of the stator, in particular the use of a new impeller. Is the latest technology of Beijing Mining Institute, which is a blade tilted an angle of the cone-shaped impeller, similar to the high speed of the centrifugal pump wheel, pumping large amount of pulp, indenter small, low power consumption and simple structure.

A porous cylindrical air distributor is also provided in the impeller chamber so that the air can be uniformly dispersed in most of the area of the impeller blades, providing a larger slurry-air interface.

SF-type flotation machine in operation, the motor through the V-belt drive spindle, so that the lower part of the impeller rotation. The main feature of this flotation machine is the performance of the impeller. Impeller with a back-tilting double-sided blade, can achieve the tank slurry cycle. When the impeller rotates, the pulp in the upper and lower impeller cavities are centrifuged under the action of the upper and lower blades (ie, the main and auxiliary blades), and the negative pressure zone is formed in the upper and lower impeller cavities. At the same time, the upper part of the slurry is sucked into the upper impeller chamber through the circulation hole on the cover plate to form the slurry circulation. The centrifugal force is larger than the three-phase mixture thrown out of the upper blade, So that its centrifugal force increases, thereby enhancing the upper wheel wheel cavity of the vacuum, played a role in auxiliary suction. The lower leaves to the surrounding thrown out of the pulp, the lower pulp to the center to add, so that the formation of the pulp under the cycle. And the air through the suction pipe, the central tube was sucked into the upper impeller chamber, and was sucked into the slurry mixed to form a large number of small bubbles, through the cover steady flow, evenly dispersed in the tank, the formation of mineralized bubbles. Mineralized bubbles float to the foam layer, which is the foam product by the scraper.

The characteristics of the mechanical agitated flotation machine: the pulp is inflated and stirred by the mechanical stirrer to achieve, are outside the air self-priming flotation machine, inflatable mixer with a pump-like suction characteristics, both self-priming air Self-priming pulp.

XJK flotation machine (commonly known as A type) its characteristics are:

First, the cover is installed with 18 to 20 guide vanes.

Second, the impeller, cover, vertical axis, intake pipe, bearings, pulleys, etc. assembled into a whole component.

Third, the trough around the installation of a circle of upright wing plate, to prevent the slurry to produce eddy current.

SF-type flotation machine is self-priming, self-priming mechanical agitated flotation machine, mainly used for non-ferrous metals, ferrous metals and non-metallic mineral selection.

working principle:

SF flotation machine is characterized by the use of back-tilting double leaves, which consists of the main and auxiliary leaves, the role of the main leaves one inhaled enough air, and second, inhalation of pulp. The role of the secondary leaves is mainly to suck the lower part of the pulp to the surrounding. This part of the pulp than the main leaves of the gas-liquid mixture than the large, therefore, the centrifugal force is also large, the gas-liquid mixture has a greater role in accelerating the impeller cavity to increase the vacuum, improve the flue suction capacity, The other effect of the secondary blades is to circulate the lower pulp and increase the distance from the impeller to the bottom of the tank without producing coarse sand.

When the impeller rotates, a negative pressure zone is formed in the impeller cavity, and the air is sucked into the impeller chamber through the suction pipe and the central cylinder. At the same time, the slurry is sucked into the impeller chamber through the central cylinder and the circulation hole on the stator. Gas and liquid mixture with a large tangential and meridional momentum away from the impeller blades, through the stator more evenly dispersed into the tank, a large number of mineralized bubbles and a part of the pulp rose to the upper flotation tank, the remaining pulp back to the lower part of the recycling The

Mine flotation machine instructions:

Before starting the machine should first check the various parts of the bolt, stop before the start should be manually on behalf of the rotation, to prevent the deposition of sediment to increase the motor load, the work should be carefully adjusted gate height, so that the liquid surface to maintain stability, at any time on the slurry slurry The foam blows into the groove. Impeller and the stator should be maintained at a certain distance, wear should pay attention to replacement, the pump bearing every three months to maintain time.

Wearing parts: impeller, stator.

Flotation machine installation:

The flotation machine itself has good stability, so the installation does not require a special basis, but must ensure that the level of overflow weir. The installation of the flotation machine is usually carried out according to the following steps (for example, type A flotation machine):

1, before the installation of the inspection. Flotation machine installed before the packaging of the warranty and anti-corrosion oil removed, check the packing list carefully check the various parts and parts, if found a defect should try to eliminate. If necessary, disassemble cleaning, calibration and adjustment, and check that all parts are complete.

2, the inspection of complete sets of components. Flotation machine should check the number of parts before installation, to determine the required left and right installed program. According to the total flotation machine check zero, the number of parts and so on.

3, flotation machine installation deviation check.

(1) the installation of vertical and horizontal center limit deviation of ± 3mm, and installed in the same center line on the flotation machine, the center straightness tolerance of 3mm;

(2) installation height limit deviation of ± 5mm, and installed in the same centerline flotation machine, the relative elevation difference of not more than 3mm;

(3) the installation of vertical and horizontal horizontal tolerance of 0.30 / 1000.

4, the assembly and installation of the tank.

(1) the tank body in the direction of the body should be maintained in the horizontal level;

(2) into the row of flotation machine installed in the tank after the overflow weir should be level, height difference of not more than 5mm;

(3) into the row of flotation machine installed in the tank into the groove relative position difference of not more than 5mm;

(4) the connection of the tank body using welding;

(5) After positioning the tank, it should be welded together with the mounting plate, platform or embedded parts.

5, vertical axis part of the inspection and transmission assembly.

(1) Rotor (impeller) and the stator (cover) between the radial and axial clearance in line with the requirements of the drawings to ensure the flexibility when the impeller idling;

(2) vertical shaft drive installation must be corrected when the motor center line vertical, motor triangular pulley and the spindle on the V-belt pulley height is consistent and the degree of tension of the set of V-belt pulley.

6, the installation of foam scraper.

(1) correct the linearity and level of the foam scraper;

(2) check the scraper bearing installation is correct to prevent the card shaft, scraper rotary shaft bearing coaxial tolerance of Φ2mm;

(3) scraper rotary shaft and overflow weir should be parallel to the parallelism tolerance of 3mm;

(4) The gap between the blade blade and the weir is 4-6 mm.

7, the requirements of the middle room.

(1) the installation of the middle chamber and the tank and the gate and the middle of the room between the contact should be close to each other without gaps;

(2) slurry slurry to adjust the gate after installation to ensure flexibility.

Precautions:

If flotation pulp contains more slime, it will bring a series of adverse effects on flotation. The main effects are the following:

① easily mixed in the foam products, so that grade grade decline.

② easy to cover the surface of coarse particles, affecting the coarse grain flotation.

③ adsorption of a large number of agents, increase the consumption of pharmaceuticals.

④ make the pulp sticky, inflatable conditions deteriorate.

Product Application:

Flotation machine is mainly used for sorting copper, zinc, lead, nickel, gold and other non-ferrous metals, can also be used for ferrous and non-metallic rough selection and selection. Flotation machine for non-ferrous metal selection, can also be used for non-metallic such as: coal-stone, talc selection. The flotation machine is driven by the motor V-belt drive to rotate the impeller, resulting in centrifugal action to form negative pressure. On the one hand, the suction air is mixed with the pulp. On the one hand, the mixing pulp is mixed with the drug, and the foam is refined to make the mineral stick , Floating to the pulp surface and then form a mineralized foam. Adjust the height of the gate, control the liquid surface, so that useful foam scraped by the scraper.

Product specifications and technical parameters:

model

Volumem3 | Impeller diameterMm | Impeller speedR/min | Processing capacitym3/min | Groove sizeMm | Impeller powerKw | Scraper powerKw | weightkg | |

SF 3A | 0.37 | 300 | 386 | 0.2-0.4 | 700/700/750 | 2.2 | 0.55 | 466 |

SF 4A | 0.7 | 350 | 400 | 0.3-0.9 | 900/820/750 | 3 | 0.55 | 860 |

SF 5A | 1.2 | 450 | 312 | 0.6-1.2 | 1100/1100/1100 | 5.5 | 1.1 | 1360 |

SF 6A | 2.8 | 550 | 268 | 1.5-3.5 | 1700/1600/1150 | 11 | 1.5 | 2126 |

SF 7A | 4 | 650 | 220 | 2-4 | 1850/2050/1200 | 15 | 1.5 | 2579 |

SF 8A | 8 | 760 | 191 | 4-8 | 2200/2900/1400 | 30 | 1.5 | 4118 |