Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Wet-type permanent magnet magnetic separator:

Wet-type permanent magnet cartridge is a magnetic separator commonly used in iron ore concentrator, which is suitable for sorting strong magnetic minerals.

The wet-type permanent magnet magnetic separator is divided into three kinds of downstream, counter-current and semi-countercurrent according to the tank structure.

Wet-type permanent magnet magnetic separator in the magnetic separation plant in addition to sorting equipment, but also for the filter before the enrichment equipment to replace the magnetic dehydration tank.

Strong magnetic field magnetic separator:

There are many types of magnetic field magnetic separator, according to the operating conditions are divided into wet and dry; according to the magnetic field is divided into electromagnetic and permanent type; according to the equipment structure is divided into disc, roller, flat ring, vertical ring, induction Roller and so on.

Wet countercurrent magnetic separator is suitable for mines, coal preparation plants and other units, for weak magnetic field wet sorting fine particles of strong magnetic minerals, or remove non-magnetic minerals mixed with strong magnetic minerals.

The machine has three kinds of tank: semi-countercurrent tank (CTB); downstream tank (CTS) and counter-current tank (CTN), respectively, for different sorting particle size and different sorting process requirements. Strong magnetic has 9 grades from A --- R level

Product features are: the use of computer optimization design, the magnetic circuit is reasonable and strict selection of high coercivity, high remanence of the permanent magnet, to ensure that the magnetic in a long time does not reduce the protection of the user's long-term interests, the overall structure of reliable and durable.

Product structure and principle:

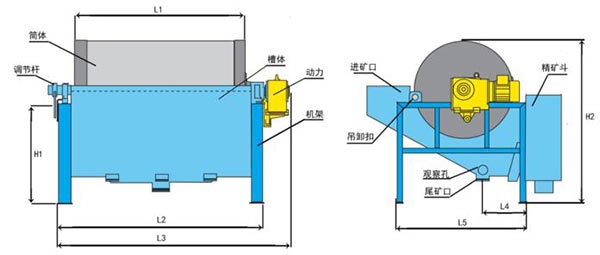

Wet permanent magnetic drum magnetic separator mainly by the cylinder, roller, brush roller, magnetic, tank, transmission 6 parts. The cylinder is made of 2-3mm stainless steel plate welded into a tube, the end cap is cast aluminum or the workpiece, and the stainless steel screw is connected with the cylinder.

Wet magnetic separator for the size of 3mm below the magnetite, pyrrhotite, roasting ore, ilmenite and other materials, wet magnetic separation, but also for coal, non-metallic minerals, building materials and other materials in addition to iron operations.

Wet magnetic separator magnetic system, the use of high-quality ferrite material or with rare earth magnet composite, tube table average magnetic induction strength of 100 ~ 600mT. According to user needs, can provide downstream, semi-countercurrent, counter-current and other different forms of magnetic separation. The magnetic separator has the advantages of simple structure, large processing capacity, convenient operation and easy maintenance. Mineral processing equipment The process is to crush the ore to 5mm or 3mm below, and then use the permanent magnetic field field magnetic separator for wet magnetic separator magnetic tail. The process is of particular importance for energy saving, efficient use of extremely poor iron ore and improved final iron concentrate quality. Ma Gang Gaocun iron ore in order to develop the use of grade 20% of the following iron ore, the experimental study using high-pressure roller mill will be crushed to 3mm below the ore, midfield wet-type magnetic separator magnetic separation of about 40% of coarse-grained tailings, The iron content of the grinding material is increased to about 40%, and then the final iron concentrate is obtained after re-grinding. The final grade of iron ore is more than 65%, the content of SiO2 is less than 4%, and the tailings are less than 10% The In addition, Shandong Laiwu Iron Mine, Jinling Iron Mine, such as the use of hammer mill - wet permanent magnetic midfielder magnetic separator magnetic separation process, selected material particle size of -5mm accounted for more than 80%, can throw off the yield of 30% About 40% of the coarse-grained tailings.

The countercurrent wet magnetic separator is suitable for the selection and cleaning of fine-grained magnetic minerals with wet-selected ore grain size of 0.6 ~ 0mm. Because the recovery rate is higher, but the concentrate grade is low, so often used in the coal preparation industry in heavy medium recovery. Or to remove the magmatic minerals in the nonmagnetic minerals. And because the coarse-grained material is easy to block the sorting space, so the counter-current magnetic separator is not suitable for handling coarse-grained materials. The machine can be continuous to the mine and discharge, magnetic field strength, high magnetic field gradient, with high processing capacity. The principle is that when the slurry into the magnetic field, in which the strong magnetic minerals are adsorbed on the surface of the cylinder, weak magnetic and non-magnetic minerals are washed out of water flow, and adsorption on the cylinder surface of the magnetic minerals with the cylinder rotation, Magnetic field, with flushing water into the concentrate tank, complete sorting operations.

After the pulp into the tank into the tank, the water in the pipeline to the role of water, the ore was loose into the tank to the mining area. In the role of the magnetic field, the magnetic particles change, to the magnetic pole movement, and was adsorbed on the cylinder. Due to alternating magnetic pole and magnetic stirring phenomenon, mixed with magnetic or magnetic chain in the gangue and other non-magnetic minerals in the flip off, and ultimately sucked in the cylinder surface of the magnetic or magnetic lotus is the concentrate. Concentrate with the cylinder to the magnetic edge of the weakest magnetic edge. Non-magnetic or weak magnetic minerals are left in the pulp with the pulp out of the tank, that is, tailings.

The permanent magnet magnetic separator is suitable for metallurgical and mining mineral processing companies, concentrator and other enterprises and institutions and individual users, for the selection of fine particles of magnetic minerals, or to remove non-magnetic minerals mixed with magnetic minerals. I produced by the permanent magnet magnetic separator is based on the different production process of the concentrator, the nature of different minerals, the use of advanced sorting ideas, targeted design and customer practical use of the occasion to adapt to different field strength Of the tailor-made special-type magnetic separation equipment. I produced the permanent magnetic cylinder magnetic separator can significantly improve the sorting ability and sorting quality, for the local mineral processing enterprises to reduce production costs and increase economic efficiency to provide a new concept and effective way to achieve!

The magnetic field strength of the magnetic cylinder is much higher than that of the conventional permanent magnet magnetic separator, which is easy to be operated and maintained. It has obvious energy saving and energy saving performance when used in all kinds of concentrator. The magnetic cylinder of the permanent magnet magnetic separator can be equipped with three kinds of tanks, namely, semi-countercurrent tank (CTB), flow channel (CTS) and counter-current tank (CTN), to meet different requirements. Semi-countercurrent slot permanent magnet drum magnetic separator for the ore size of 0.5 ~ 0mm rough selection and selection, especially for the particle size of 0.15 ~ 0mm mineral selection; downstream tank permanent magnet magnetic separator for Ore size of 6 ~ 0mm rough selection and selection; counter-flow tank permanent magnet magnetic separator for the ore particle size of 0.6 ~ 0mm roughing and scanning, as well as coal preparation industry heavy medium recovery.

The permanent magnetic drum magnetic separator adopts professional computer software to optimize the design, reasonable structure, simple installation, easy to use, high efficiency of selection. Select "Bost" permanent magnet magnetic separator, improve the beneficiation plant economic benefits!

Permanent magnet magnetic roller performance characteristics:

Permanent magnetic roller (also known as magnetic pulley), mainly for the following purposes:

1, poor iron ore by rough or broken after the rough selection, excluding rocks and other waste rock, improve the grade, reduce the load of the next process.

2, for hematite reduction closed-circuit roasting operations will not fully restore the raw ore sorting, return to re-burn.

3, for the ceramic industry will be mixed in the porcelain mud removed, improve the quality of ceramic products.

4, coal mines, foundry sand, refractory materials and other needs of the line in addition to iron operations.

Product Application:

CTS (NB) series of permanent magnet magnetic separator magnetic field sub-rotary, fixed two kinds of institutions, fixed mainly for weak magnetic field wet sorting fine particles of ferromagnetic material, or remove non-magnetic minerals in the strong magnetic minerals , When the slurry into the magnetic field, where the strong magnetic minerals are adsorbed on the surface of the cylinder, weak magnetic and non-magnetic minerals were divided, and adsorbed in the cylinder of the strong magnetic minerals with the rotation of the cylinder was out of the magnetic field. Rotary is suitable for fine-grained (medium-strong) magnetic mineral dry election, due to the role of high-speed rotation, so that the magnetic particles of the number of times the magnetic roll is much higher than the ordinary magnetic separator, which for the destruction of magnetic agglomeration, improve the rich ore ratio has significant Effect, the mineral is sorted by the separation of magnetic and non-magnetic two, respectively, from the respective discharge port exclusion of the machine for the ore size of 6-0mm rough selection and selection.

Product specifications and technical parameters:

model | diameter (mm) | Tube length (mm) | Cylinder speed (r/min) | Feed particle size(mm) | Processing capacity(t/h) | power (kw) |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |