Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Shaker is widely used in the domestic effective re-election equipment, the selected part of the basic part of the traditional wooden bed. Practice has proved that the wooden bed is easy to deformation damage, frequent maintenance, the use of short, wood lacquer and other raw materials increasingly scarce, difficult to adapt to the requirements of production development. To this end, developed a LS-type (6-S-type) and other new fiberglass bed to replace the wooden bed. In the material, structure, manufacturing process and so on with the wooden bed is completely different, is a major innovation of the traditional wooden bed, to determine the use of mass production to promote the use of.

Production practice has proved that FRP rocking bed has a series of advantages:

1, stiffness, strength, deformation is small.

2, low water absorption, no weight gain.

3, the work surface is not easy to damage, good wear resistance, maintenance of small.

4, do not absorb moisture, not rotten, no insects.

5, anti-chemical corrosion, acid and alkali, not bogey pulp in the pharmaceutical.

6, good weather resistance, shape stability, not dry.

7, sorting performance is good, stable indicators.

8, to retain the wooden bed of the assembly size, both interchangeable installation.

I plant according to the design drawings and complete sets of technical processes to organize production, strict quality control, to ensure that the product of the technical requirements, welcomed the overwhelming majority of users to buy.

Product structure and principle:

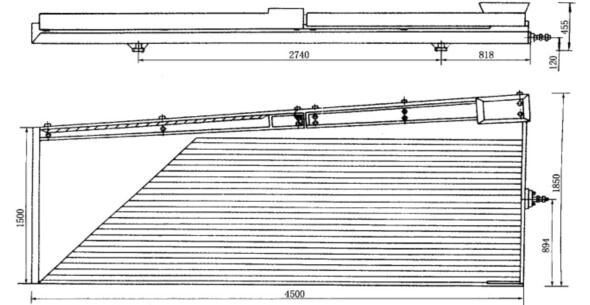

6S type FRP bed surface structure shown in Figure 1, respectively. The bed is made of polyester glass fiber reinforced plastic steel frame, the working surface is made of special wear-resistant layer. Bed with a wear-resistant material into the mold and the bed at the same time a molding, to the edge of the board and the end of the board and the end of the skeleton together without a need to add, according to user needs to determine whether the mine, Qi).

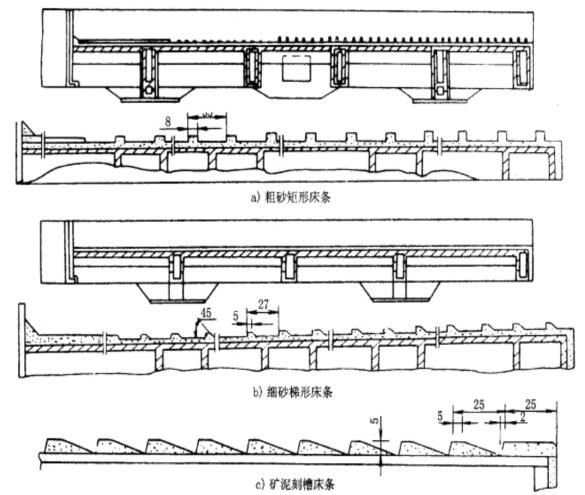

I plant production: 46 slot shaking bed (a coarse sand shaking bed), 60 slot shaker bed (a fine sand bed), 80 slot shaker bed (a fine sand bed), 90 slot shake Bed surface (a fine sand bed surface), 110 slot shaking bed surface (sand and shaking bed surface), 120 trough new straight chute bed surface (sand and shaking bed), 138 groove shaking bed Mud shaking bed), single wave shaking bed, double wave shaking bed, Taiwan floating bed;

Material is divided into: wood groove, glass steel, rubber, paint gray groove.

6S type FRP bed surface structure shown in Figure 1, respectively. The bed is made of polyester glass fiber reinforced plastic steel frame, the working surface is made of special wear-resistant layer. Bed with a wear-resistant material into the mold and the bed at the same time a molding, to the edge of the board and the end of the board and the end of the skeleton together without a need to add, according to user needs to determine whether the mine, Qi).

Figure 6 # FRP glass bed surface structure diagram

Figure 2 coarse sand, fine sand, mud shaking bed surface structure

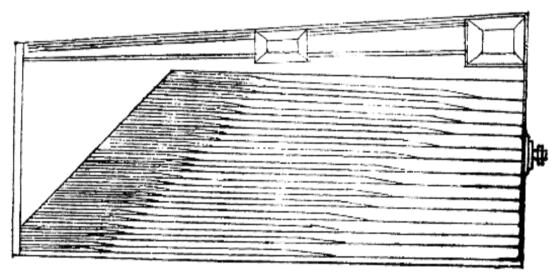

Fiberglass double curved wave shaker surface

Selection principle:

When the slurry is fed, the oblique section forces the ore particles to climb in the longitudinal direction to the oblique water flow caused by the reentry, so that the crawl speed difference and the deviation angle of the heavy and gravel are increased. The concentrate is thin and evenly discharged and discharged in a timely manner. "Two oblique straight" bed form to improve the sorting conditions, can significantly improve the control under a certain sort of control effect and recovery rate. Especially in dealing with "running sand" phenomenon and the proportion of the difference is not enough, compared with the straight slot shaker better. The shaker can be used for rough selection, selection and other sorting operations.

In the sorting operation, the choice of straight-channel shaker, single-wave shaker or double-wave shaker, the specific should also be based on the nature of the ore itself, for example, the proportion of ore, the proportion of light and heavy ore particles, The The current wide application shows that the corrugated shaker in the treatment of "running sand" phenomenon, sorting part of the difficult separation of ore, the effect is better than straight chute, is a sorting effect is better than ordinary 6-S shaker

Double-wave shaker bed surface feature is in the straight bed on the basis of the two additional oblique area (see Figure ① ③ two oblique area), a single straight bed to "two oblique two" Hyperboloid (see Figure 1).

1, a section of oblique area 2, a section of parallel bed area 3, two oblique area 4, two parallel bed area 5, smooth area 6, to the mine

7, the water tank 8, the bed gear box 9, the slope 10, the motor 11, the belt flywheel 12,

The main purpose:

Wave shaker is widely used in tungsten, tin, lead, zinc, gold, silver, tantalum, niobium, monazite, zircon, ilmenite and other mineral ore or sand ore concentrator in dealing with 3-0.019mm granular ore Of rough selection and selected operations.

main feature:

Corrugated shaker with large processing capacity; high recovery rate of ore dressing; wide adaptability and other characteristics, especially the concentrate belt is relatively stable, mineral concentrates, ore, tailings with clear, when the ore concentration, When the change occurs, the sorting situation is stable, so the operation and management is convenient.

Main structure:

The wave-type shaker consists of a steel-framed frame and a top-of-the-box epoxy resin diabase casting material bed, a cradle supported by a shaker, a shaving mechanism, and a shaker for a reciprocating drive.

The technical performance of the corrugated bed shaker:

The key to the CC-2 type shaker is to increase the bed oblique area; to reduce the smooth area of the bed; the oblique bar has a certain climb angle; The change of the longitudinal slope of the bed itself; the change of the cross-sectional area of the bed and the material of the bed surface. And with the appropriate technical parameters of the operation also has some changes. In principle, according to different selection of objects to select different technical parameters.

When the shaker in accordance with the vertical as the asymmetric reciprocating movement, so that the ore along the oblique - flat - oblique - flat trajectory, alternately repeated "squeeze", "cut", "wash", "election". The sloping beds are forced to climb the slanting water caused by the reunion in the longitudinal movement, which leads to the poor speed of the climbing of the heavy and gravel particles. The vertical and horizontal movement speed of the bed is poor. During the climb process, the role of flushing water, mineral particles flip, so caught in the heavy ore between the light ore particles were washed out, improve the sorting efficiency. Smooth area to reduce the selection of the concentrate when the sudden widening, concentrate discharge speed to speed up to avoid the deterioration of the concentrate and indicators, the performance of the phenomenon in the sorting situation is the concentrate, the mine, tailings stable operation Convenient, excellent performance and reliable.

Brief Introduction of XDM - 98 Type Micro - mud Slurry

XDM-98 micro-mud shaker is our factory according to the traditional 6-S-type, Yunxi-type shaking bed surface of the coarse sand, fine sand and mud to carry out a physical synthesis of a new type of re-election equipment. Practice has proved that the traditional shaker because of each model specifications of the bed to the complex from the rough area to the selection area are into a horizontal plane. To repeat the specifications is also a bed made of a specification, only the bed and bed divided into coarse sand, fine sand, mud and the difference between the mud. Therefore, in the production of mineral processing process, the ore particles in the bed on the loose layer, can not be based on their own needs timely delivery and tailings emissions. For the treatment of a variety of different sizes of ore, can not be effective for recycling.

XDM-98-type micro-mud shaker is the biggest breakthrough in the face to re-article of each sorting section based on the ore in the various sections of the capacity and the proportion of a reasonable allocation. As shown in (see figure). In the sorting of coarse-grained ore is not easy to cause the mine, the fine-grained ore tailings can be discharged at the same time in advance, so that the selected area of ore recovery and grade is relatively higher than other specifications of the traditional shaker surface. So the shaking bed to adapt to a wide range. Can be used for rough selection, can also be used for selection and other different operations.

XDM-98-type micro-slag shaker the size of its various parts of the assembly, retaining the 6-S-type and tin-type bed size, ready to be interchangeable. The structural part is made of polyester steel fiber reinforced steel skeleton, the working surface layer for the special wear-resistant materials into the mold and bed forming.

XDM-98-type micro-slag shaker from the development and production of our plant has been put on the market, because of its face to repeat the rational design of the specifications and the use of traditional shake bed surface comparison test, the effect is remarkable, by the user's welcome. I plant is now mass production to promote the use of.

Bed installation and commissioning, operation and maintenance, storage and transportation of traditional glass steel shaker the same.

Product Application:

Tungsten, iron, manganese, chromium, titanium, bismuth, lead, gold and other colored, black, dilute precious metal minerals, sorting 4-0.02 mm for the selection of 2-0.02 mm ore and slime grade tungsten, tin, tantalum Of the pyrite; the appropriate change in the type of bed after the election of coal and slime; and the sorting of other components with sufficient weight difference and the composition of the appropriate size of the mixed material.

Can be used for rough selection, selection, cleaning and other different operations, sorting coarse sand (2-0.5mm), fine sand (0.5-0.074mm), mud (-0.074) and other different size.

The sorting mechanism is the same as the wooden bed. The use of the difference between the weight of the selected minerals, the bed to provide the differential movement, slope water and different types of bed, so that the granules in the bed loose layer, selective transport, the formation of fan-shaped bed With the output of different rich and poor products.

Product specifications and technical parameters:

name | Unit | Coarse sand bed | Fine sand bed | Slime bed surface | |

Bed size | length | mm | 4450 | 4450 | 4450 |

Drive width | mm | 1855 | 1855 | 1855 | |

Concentrate wide | mm | 1546 | 1546 | 1546 | |

Maximum to the degree of ore | mm | 2 | 0.5 | 0.15 | |

To the amount of ore | t/d | 30-60 | 10-20 | 15-25 | |

Concentration of ore | % | 25-30 | 20-25 | 15-25 | |

Itinerary | mm | 16-22 | 11-16 | 8-16 | |

frequency | f | 45-48 | 18-53 | 50-57 | |

Bed cleaning water | t/d | 80-150 | 30-60 | 10-17 | |

Bed lateral slope | degree | 2°30-4°30 | 1°30-3°30 | 1°-2° | |

Bed longitudinal slope | % | 1.4 | 0.92 | ----- | |

Bed angle | ° | 32°-42° | 40° | 42° | |

Processing area | M2 | 7.6 | 7.6 | 7.6 | |

Bed length ratio | 2.6 | 2.6 | 2.6 | ||

Bed surface shape | rectangle | Serrated | triangle | ||

According to the different location of the ore, shaker can be divided into left-type shaker and right-type shaker two forms. Standing on the side of the shaking bed to look forward to the waiter, the left side of the feed for the left-style shaker, the right side of the feed for the right-style shaker.