Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

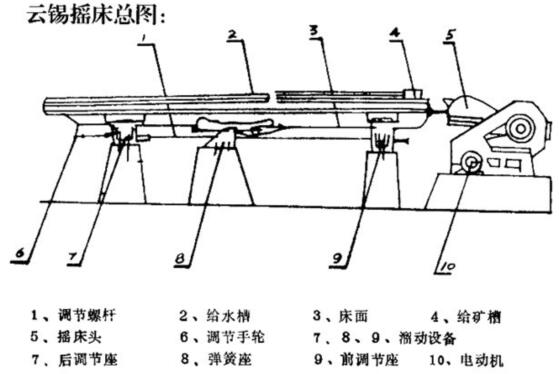

The full set of production drawings of Yunnan Tin shaker is produced in strict accordance with the standard drawings of Yunnan Tin Company, which is mainly used for all kinds of non-ferrous metal mines. Especially for more than a metal mine in particular can play its miraculous function. It can sort out the following two kinds of non-ferrous metal re-election and selection. After years of mine production practice proved: Yunxi shaker with stable performance, high efficiency, stable, low noise and easy maintenance and so on. Welcomed by the majority of mine users.

Product structure and principle:

Yunxi shaker mainly by the bed, bed, slippery equipment composed of three parts. Bed by the bed frame part and to the mine and other components. The bed is divided into coarse sand bed and grooved bed. Select the appropriate bed (table) according to the different size and concentration of ore dressing. Bed support in the slippery equipment, the bed by the bed of the bed connected to the bed, driven by the bed to make the bed reciprocating exercise for mineral processing.

The bedside is driven by an eccentric shaft to drive the rocker arm to push the joystick arm into the coupling screw, thus causing the screw to reciprocate. Bedside lubrication bearings using Z Q S n 5 - 5 - 5 material as a sliding bearing, with a small noise, flexible rotation and so on.

Slip the device part is mainly used to adjust the mineralization equipment required slope, the use of hand wheel to adjust the slope of the pallets, so that the bed slope.

Technical performance:

Name | Specifications | Technical performance | ||||

Bed size | 4436×1825×1536m/m | Shaker category | Stroke (m/m) | Red times (per / Score) | Total water consumption (M3 / 台 日) | Processing capacity (T / Taiwan) |

Dimensions | 5454×1825×1242m/m | |||||

Adjustable stroke | 8—22m/m | Coarse sand bed | 16—22 | 240—290 | 190 | 30 |

Equipped with motor | JO2—31—61.5千瓦 | Cashmere bed | 10—16 | 300—320 | 80 | 8 |

Total weight | 1012公斤 | Carved bed | 10—16 | 330—340 | 50 | 5 |

Motor triangular pulley and belt selection:

Shaker category | Triangular pulley size(m/m) | V-belt model | |||

D(Outside diameter) | D1(Caliber) | d(the inside diameter of) | H(width) | ||

Coarse sand bed | Φ117 | Φ110 | Φ 28+0.023 | 53 | A1800 |

Fine sand bed | Φ137 | Φ130 | Φ28+0.023 | 53 | A1800 |

Carved bed | Φ147 | Φ140 | Φ28+0.023 | 53 | A1800 |

Sliding bearing specifications, quantity:

Name | Material name | Specifications | Quantity |

Eccentric bushing | Z Q S n 5 — 5 — 5 | Φ60×84 | 1 |

Rocker arm bushing | Z Q S n 5 — 5 — 5 | Φ 65×158 | 1 |

Bearing | Z Q S n 5 — 5 — 5 | Φ 70×160 | 2 |

Positioning bearing sleeve | Z Q S n 5 — 5 — 5 | Φ60×120 | 2 |

Connecting rod | Z Q S n 5 — 5 — 5 | 1 |

The use and maintenance of the Tin Tin shaker:

After the use of Yunxi shaker, the necessary maintenance and repair should be carried out, because the shaker parts often maintain a good condition, not only can affect the performance of mineral processing and efficiency indicators, but also to increase its life.

General precautions for using shaking surfaces:

1, the bed of the paint layer has a certain brittle, so can not be strong beat, collision.

2, in order to avoid deformation of the bed paint layer, not placed high temperature and heavy objects.

3, in order to prevent water infiltration caused by deformation of the bed surface and affect the deformation of the paint layer, not strictly on the bed nail.

4, in order to ensure uniform flow film, should avoid oil pollution bed.

5, the use of the shaking bed in order to maintain the quality of manufacturing, handling and stacking and installation process must pay special attention. Generally require handling and stacking should avoid injustice or overlap and should be sideways, so that the ore side down, and to prevent rain and sun.

Precautions for using the shaking head:

1, in the use of tin shaker, must be selected according to the other technical conditions to select the stroke Chong times.

2, bedside part of the sliding bearing is used Z Q S n 5 - 5 - 5 material. Although made by precision machining, but should ensure that the use of lubricants within the box to prevent lubrication of the bearing due to lack of oil caused by wear and tear.

3, the bed after a certain period of time, when the sliding bearing natural wear and tear, should be based on the degree of wear and tear to replace the sliding bearing.

4, shaker in use, should pay attention to keep the bed part of the clean, to prevent the ore into the bed by the ore, resulting in unnecessary wear parts.

Use the slippery equipment section to be aware of:

1, adjust the slope of the bed slope, should be selected according to the technical conditions of mineral to determine the qualified slope of the slope.

2, sliding equipment, slip bearings, the use of H T15-30 made of materials. In use should be kept slippery bearing enough oil, so as not to slip the bearing should not wear.

3, the spring seat part of the spring is to pull the bed frame, so that the bed in the bed to promote the reciprocating movement under the elastic. Therefore, the use of the spring should not be too tight or too loose, should be able to keep the bed can be a smooth reciprocating exercise is appropriate.

Installation of Tin Tin Shaker:

The new factory is located in the factory with the product quality brochures and installation of the base map. Bed and bed center as well as height and slippery part of the cement foundation with slippery equipment and bed size installation construction personnel must be installed in strict accordance with the requirements of the installation drawings.

Product Application:

The shaker is mainly used for a variety of non-ferrous metal mines. Especially for more than a metal mine in particular can play its miraculous function. It can sort out the following two kinds of non-ferrous metal re-election and selection. After years of mine production practice proved: Yunxi shaker with stable performance, high efficiency, stable, low noise and easy maintenance and so on. Welcomed by the majority of mine users.

Product specifications and technical parameters: