Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Double bucket diaphragm jig is divided into two types: left and right type. The jig is a fixed sieve. Applicable to the selection of metal ore, such as tungsten, gold-bearing sand, selected tin, etc., can be used for election of fine particles, can also be used for selected coarse materials, the maximum particle size of 6-8mm, but in In the case of individual selection, the maximum grain size is 12 mm.

Product structure and principle:

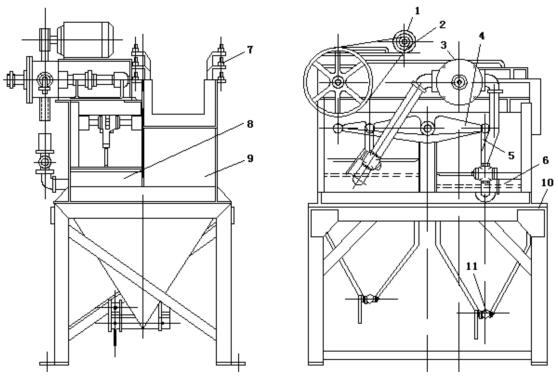

1 - motor; 2 - drive part; 3 - water separator; 4 - rocker;

5-link; 6-septal membrane; 7-jaw chamber; 8-septal chamber;

9 - Junction chamber; 10 - Rack; 11 - Drainage plug

LTS300 × 450 double bucket diaphragm jig structure consists of: the fuselage, transmission, water separator, diaphragm and live bolt and other major components, the body has two sizes of jumping bucket, each diaphragm with less than the end of the partition Will be divided into jumper area and diaphragm area two parts. Jigging process is by the rubber diaphragm for reciprocating motion caused by the media (water) to carry out the agitation. The motor through the V-belt to drive the pulley rotation, so that the eccentric shaft on the link up and down movement, and the connecting rod connected to the rocker also up and down movement, rocker and other two connecting rods connected rubber diaphragm, so that the diaphragm get up and down reciprocating Movement, jogging.

Depending on the size of the ore being treated, you can change the stroke of the connecting rod and select a different stroke in order to obtain the best jigging effect. Change the way to change the small pulley, there are two red times: 322 times / minute; 420 times / minute. Select the stroke method to loosen the set screw and nut, pull out the positioning pin, rotate the eccentric adjustment sleeve and the relative position between the eccentric shaft, there are 11 different strokes (0-25.3mm).

As a result of the working sieve above a sieve, so the jig can be used to deal with uneven size of the material. (Note: This screen is not available according to the order requirements) selected ore was sent to the jogging room, due to the role of the diaphragm, the ore particles in the media by the proportion of stratification; fine and heavy particles through the artificial bed particles gap And the sieve, sink in the jigging bucket of the mine, the upper coarse and light ore particles (minerals) by the media flow to the sieve at the end of the discharge port, because the jaw room than the lower jaw position 50mm, so light ore particles through the front chamber after the overflow into the back room, once again by jig. According to the need to adjust the level of the tail plate to control the size of the discharge. The concentrate in the storage bucket is periodically discharged from the discharge pipe.

At work, the motor drives the pulley through the V-belt, so that the connecting rod on the eccentric shaft moves up and down, and the rocker arm connected with the connecting rod moves up and down, and the other two connecting rods on the rocker are connected with the rubber diaphragm, Up and down reciprocating movement, the jigging dressing. As a result of the work of the screen above the addition of a sieve (Note: This screen is not required according to the order requirements), so the jig can be used to deal with uneven size of the material.

The company's latest improved LTP300 × 450 dual chamber diaphragm jig and the structure of the map slightly deviated, do not elaborate here.

Jigging process is by the rubber diaphragm for reciprocating motion caused by the media (water) to carry out the agitation. When the selected ore is fed into the jogging room, the granules are stratified by the proportion of the particles due to the agitation of the septum. The fine and heavy ore particles pass through the gap and sieve of the artificial bed particles, In the ore storage, the upper coarse and light mineral particles (minerals) flow through the medium flow to the sieve end of the discharge port, because the jaw room than the location of the jaw lower 50mm, so light ore particles through the front panel Overflow into the back room, again by jig. According to the need to adjust the level of the tail plate to control the size of the discharge. The concentrate in the storage bucket is periodically discharged from the discharge pipe.

Product Application:

For the selection of gold, tin, tungsten, titanium, hematite, iron ore, coal and other minerals, especially in the field of manganese ore beneficiation has been widely used.

Product specifications and technical parameters:

Name specification | Number of rooms | Sieve area (Mm) | Ore grain size (Mm) | Production capacity (Ton / hour) | stroke (Mm) | Red times (per / Score) | Add water (Tons) | Water pressure (Kg / cm²) | Motor Power (kw) | weight(kg) |

100×150 | 1 | 0.015 | -3 | 0.018-0.6 | - | 420 | - | 1-1.5 | 0.55 | 130 |

300×450 | 2 | 0.27 | -12 | 3-6 | 0-26 | 322 | 2-4 | 1-1.5 | 1.1 | 745 |

1000×1000 Under the type Cone jig | 2 | 2 | 1-5 | 10-25 | 0-26 | 200-350 | 60-80 | 0.6-2 | 1.5 | 1700 |

370 × 370 under the move Cone Diaphragm Jig | 2 | 0.274 | 6 | 1-3 | 5-25 | 200-250 | 2-5 | - | 1.1 | 240 |

Leather trapezoidal lateral movement Diaphragm jig | 3 | 2.7 | -3 | 12.5-37.5 | 13-21 | 170-230 | 60-90 | 2 | 1.1 | 2000 |

Precautions for use:

1, before starting to check the screws are tightening the components, retaining bolts, bucket body can not leak.

2, the pressure of the oil Tsui Department should pay attention to regular filling grease.

3, the first empty operation is normal, only to allow the load to run.

4, rubber diaphragm and the V-belt is not allowed to stain the oil.