Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

RXT-type drum washing machine to introduce foreign technology to use sand, stone deslimatization, drum built-in single or double-layer circular screen can be two or three different specifications of sand, stone products. Mainly used for mineral processing before the ore cleaning operations, improve the process of mineral processing indicators, commonly used in manganese ore, iron ore, limestone, tungsten ore, silica ore and so on.

Drum washing machine, also known as the election machine for the implementation of mineral processing before the process of ore cleaning, improve the process of mineral processing indicators, commonly used in manganese ore, iron ore, limestone, tungsten, tin, silica sand and other minerals. Washing machine is used for black and nonferrous metallurgical mining, steel, metallurgy, chemical, building materials used to clean the ore, stone large equipment, washing machine processing capacity is to meet the large productivity of ore, stone cleanliness requirements The ideal equipment for the enterprise. Wash the ore to avoid the mud in the mineral raw materials in the mud clogging crushing and screening equipment.

Product structure and principle:

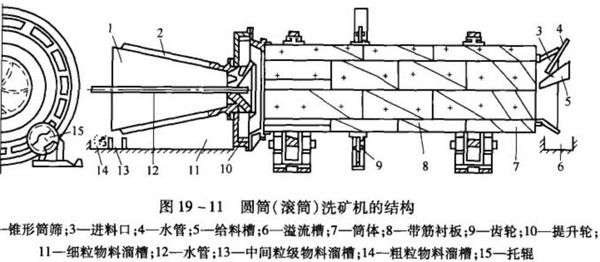

The cleaning cylinder is supported by four tugs, the motor drives the reducer, and the size gear drives the cleaning cylinder to rotate at low speed. The aggregate containing the mud group and the stone powder is fed from the feed inlet into the rotating drum, and the wear-resistant rubber lining plate which is installed in the cleaning drum is continuously lifted off from the feed end to the discharge end The process of repeated cycles, and was washed forward or reverse rinse washed rinse, clean the aggregate through the discharge tube after the end of the screen sieve dehydration after discharge. Wastewater containing sludge flows through the perforated baffle through the discharge or feed end.

Circle (Roller) Drumers use rotating cylinders and internal scraper and their own pebbles and rocks to break down clays, lumps and soft matter. The cylinder of the washing machine slowly rotates, the material with different thickness and the water are simultaneously stirred and stirred to effectively separate the useful minerals from the muddy soil and the clay. Dispersed homogeneous slurry-like material is sent to the tail by the cylinder and discharged from the overflow port to the conical screen for sieving. The conical sieve excludes material that is larger than the granularity of useful minerals, and the sieve can directly enter a variety of mineral processing equipment, such as centrifugal concentrator, spiral chute, jig, and chute.

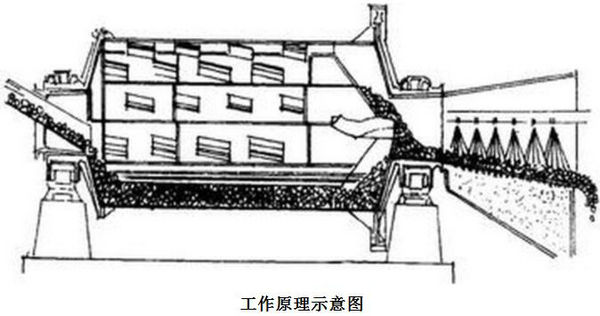

Working principle diagram

Features:

1. Drum washing machine equipment has a large feeding capacity of the characteristics, it is mainly used for artificial sand sand less than 80mm aggregate to mud.

2. After the drum washing machine equipment after washing the aggregate mud content can be less than 0.5%, water content of less than 2%.

3. High degree of integrity: In addition to finished product stacking belt conveyor, all systems are integrated in a whole framework, both to ensure the integrity of the equipment and leave a moderate maintenance and inspection space.

4. Drum washing machine equipment, a high degree of integrity to facilitate the construction site storage or transshipment transport, convenience and safety.

5. Work reliability: drum washing machine equipment, the core of the stone system using the mixer mixing principle, the raw material in the mixing tube by the continuous spiral blade rolling, pushing and the friction between the role of the material, the role of strong natural reliability.

6. Drum washing machine equipment has a strong economic usability, storage hopper capacity of 8M3, so that the loader reasonable arrangements for the main equipment (such as mixing station) and washing stone machine feeding time, to avoid the loader in different materials Point and the frequent transposition between raw materials, storage hopper width greater than 3 meters, but also easy loading loader, reduce labor intensity.

7. Drum washing machine equipment is also equipped with waste water recycling, water automatic compensation and finished products from the machine and then leaching, in the mud discharge function of the tank, the tank capacity of 2M3.

8. Finished stone can be stacked can also be warehousing or bucket (such as: put into the ingredients machine stone hopper).

Product Application:

Roller washing machine is also called cylinder washing machine, drum selection machine, drum washing machine on the gravel cleaning degree is very high, in many sand and gravel production line drum stone washing machine has also been widely used. Drum washing machine equipment is mainly used in construction sites, gravel plants, prefabricated plants and hydropower sites with a large number of sand and gravel, screening operations can also be used for ore screening operations. Or a large equipment for the black and nonferrous metallurgical mines, steel, metallurgy, chemical industry, building materials used to clean ore and stone materials, the drum washing machine processing capacity is to meet the large productivity of ore, stone cleanliness requirements The ideal equipment for the enterprise. Wash the ore to avoid mud minerals containing raw materials in the clogging and screening equipment, raw materials such as containing soluble or harmful ingredients should also be washed ore.

Product specifications and technical parameters:

model | Cylinder size(m) | Screen (mm) | Feed particle size(mm) | Water pressure (Mpa) | Water consumption per ton of mineral(M3/t) | Processing capacity(T/h) | spinning speed(r/min) | power(kw) | weight (Kg) |

RXT1030 | Φ1.0×3.0 | ≥5 | ≤100 | 0.4~0.5 | 1.5~4 | 10-20 | 25~28 | 15 | 4800 |

RXT1230 | Φ1.2×3.0 | ≥5 | ≤100 | 0.4~0.5 | 1.5~4 | 20-30 | 23~25 | 18.5 | 5800 |

RXT1545 | Φ1.5×4.5 | ≥5 | ≤150 | 0.4~0.5 | 1.5~4 | 30-50 | 18~22 | 30 | 6900 |

RXT1560 | Φ1.5×6.0 | ≥5 | ≤150 | 0.4~0.5 | 1.5~4 | 50-80 | 18~22 | 37 | 8300 |

RXT1845 | Φ1.8×4.5 | ≥5 | ≤170 | 0.4~0.5 | 1.5~4 | 80-100 | 20~21 | 45 | 11800 |

RXT1860 | Φ1.8×6.0 | ≥5 | ≤170 | 0.4~0.5 | 1.5~4 | 90-120 | 20~21 | 45 | 12800 |

RXT2060 | Φ2.0×6.0 | ≥5 | ≤210 | 0.4~0.5 | 1.5~4 | 120~160 | 19~20 | 55 | 14800 |

RXT2265 | Φ2.2×6.5 | ≥5 | ≤230 | 0.4~0.5 | 1.5~4 | 160~180 | 19~20 | 55 | 16500 |