Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Mine mixing tank for a variety of metal ore, mainly used for pre-flotation mixing, is a good mixture of pharmaceutical and pulp can also be used for other non-metallic mineral mixing. It is used at a concentration of not more than 30% (by weight) of the fixed component of the particle size is less than 1mm. It is in the form of flat-bottomed barrel-shaped radiation cycle spiral impeller mechanical agitation.

Product structure and principle:

Mine mixing tank is divided into two types: XB-type ordinary mixing bucket and XBT-type lifting bucket.

The main difference between the two is that the lifting mixer is mainly used for mixing the pulp and flotation agent with a concentration of not more than 30% and a specific gravity of not more than 3.5, and the product can be stirred while the slurry is raised to A certain height, because of this feature, lifting the mixing tank on the gap is not very good selection of the field.

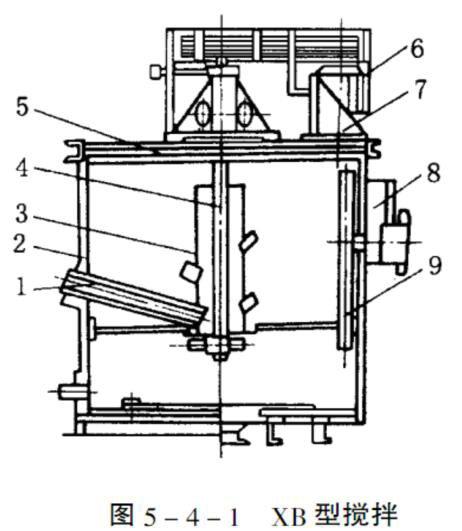

XB-type mixing tank structure and schematic diagram is as follows:

1. To the mine pipe 2. Tank off 3. Circulation tube 4. Drive shaft 5. Beam

6. Motor 7. Motor bracket 8. Overflow 9. Coarse sand pipe

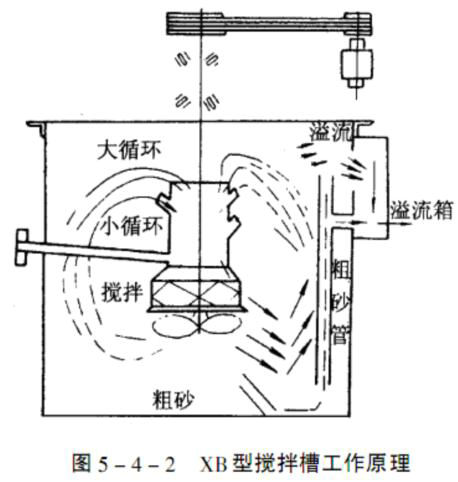

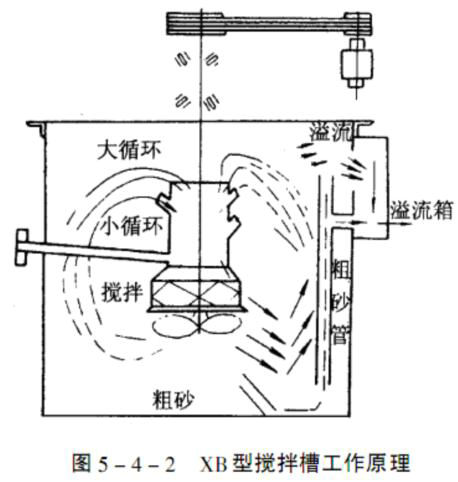

Mine working principle of the mixing tank diagram:

When the machine is working, under the rotation of the impeller, the pulp and the medicine produce large and small circular motion, and the slurry and the medicine in the whole tank are uniformly mixed and the mixed suspension is discharged from the overflow port.

Instructions for use:

1. Before using the pump head bolts, turn the pump shaft on behalf of the round is flexible, and then start running mixer, the other with the flotation machine;

2. Weak parts: impeller, stator;

3. Mixers and automatic feeder, must be clean inside, especially in winter, this can extend the life.

Features:

1. Compact structure, good sealing, and set the blanket in the feed port to prevent water mist reverse;

2. Mixing evenly, stirring the blade was fan-shaped, stirring and medium contact area;

3. nozzle multi-row settings, uniform water and can be adjusted;

4. The residual gray rate is low, the bottom of the box set to ensure that there is no dead ends.

5. Mine mixing cylinder equipment, advanced performance, product quality and stability, mixing evenly, the material quickly.

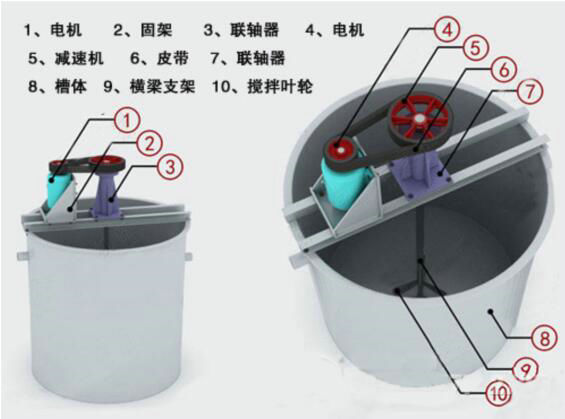

Design of XBT-1500 Lifting Mixer

1. to the ore pipe 2. baffle 3. impeller 4. trough 5. spindle

6. Bracket 7. Bearing body 8. Drive 9. Drainage port

Lifting type mixing bucket structure: mainly by the groove off, bracket, motor, impeller and transmission components.

The lifting tank is driven by the electric motor through the belt and the impeller shaft to drive the impeller rotation. The pulp and the flotation agent circulate in the tank under the centrifugal force generated by the impeller, so that the medicine is evenly distributed among the pulp, Barrel of the mixing pulp at the same time, the impeller with its own centrifugal force from the bottom of the pulp into the slurry after the inhalation, so as to achieve the purpose of upgrading the pulp, lifting mixer to ensure that the pulp to enhance the height, we must pay attention to the impeller and the bottom plate Between the gap size, the general gap should be adjusted between 6-30mm is appropriate.

Installation and maintenance:

Maintenance of the machine is an extremely important regular work, it should be extremely operational and maintenance and other closely with the full-time staff should be on duty inspection.

Maintenance of the machine

1, the bearing bear the full load of the machine, so good lubrication on the bearing life has a great relationship, it directly affects the machine life and operating rate, which requires the injection of lubricants must be clean, the seal must be good, the machine Main oiling (1) Rotary bearings (2) Roll bearings (3) All gears (4) Movable bearings, sliding surfaces.

2, the new installation of the wheel prone to loose must be regularly checked.

3, pay attention to the work of the various parts of the machine is normal.

4, pay attention to check the wear parts of the wear and tear, pay attention to replace the wear parts.

5, put the activities of the chassis plane, should be out of dust and other objects in order to avoid the machine can not break the material when the activities of the bearings can not move on the chassis, resulting in serious accidents.

6, bearing oil temperature rise, should immediately stop the cause of the check to be eliminated.

7, rotating gear in the operation if the impact should immediately stop the inspection and eliminate

Install the test

1, the equipment should be installed on the basis of the level of concrete, with anchor bolts.

2, the installation should pay attention to the main body and horizontal vertical.

3, after installation, check the various parts of the bolt without loosening and whether the mainframe door fastening, if any fastening.

4, according to the power of the device configuration power lines and control switches.

5, check is completed, the empty load test, the test can be normal production.

Product Application:

Mine mixing tank for a variety of metal ore, mainly used for pre-flotation mixing, is a good mixture of pharmaceutical and pulp can also be used for other non-metallic mineral mixing

Product specifications and technical parameters:

The internal dimensions of the cylinder | Effective volume | Mixer | Motor | Dimensions | weight | ||||

diameter | height | Impeller diameter | Impeller speed | model | power | Total height | The maximum length | ||

mm | mm | m2 | mm | r/m | kw | mm | mm | kg | |

750 | 750 | 0.26 | 240 | 530 | Y90L-4 | 1.5 | 1241 | 939 | 228 |

1000 | 1000 | 0.58 | 240 | 530 | Y100L-6 | 2.2 | 1665 | 1300 | 658 |

1200 | 1200 | 3.6 | 300 | 480 | Y100L-6 | 3 | 1800 | 1420 | 760 |

1500 | 1500 | 2.2 | 400 | 320 | Y132S-6 | 3 | 2386 | 1690 | 861 |

2000 | 2000 | 5.46 | 550 | 230 | Y132M2-6 | 5.5 | 3046 | 2381 | 1240 |

2500 | 2500 | 11.2 | 625 | 230 | Y160M-6 | 7.5 | 3546 | 2881 | 3462 |

3000 | 3000 | 19.1 | 700 | 210 | Y200L-6 | 18.5 | 4325 | 3266 | 4296 |