Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Sand washing machine (sand washing machine) is a kind of sand washing equipment used in the sand making machine. The sand washing machine (sand washing machine) can wash the sand Stone powder and impurities, thereby improving the quality of sand. Sand washing machine (sand washing machine) is mainly used for construction site, sandstone plant, concrete dam concrete site, post and telecommunications pole factory to be unit sand and casting sand, glass factory quartz sand and oil well backfill sand washing, Grading and dehydration.

Product structure and principle:

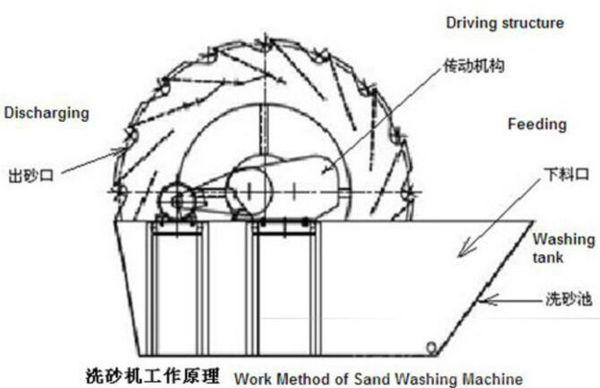

working principle

When the bucket sand washing machine work, the motor through the V-belt, reducer, gear slow down after the impeller slow rotation, gravel has a trough into the tank, driven by the impeller rolling, and grinding each other to remove the sand The surface of the impurities, while the destruction of the sand vapor covered with water vapor, in order to facilitate dehydration; at the same time add water, the formation of a strong water, the impurities and the proportion of small foreign body away from the overflow outlet tank to complete the cleaning effect. Clean sand and gravel from the leaves away, the last gravel from the rotation of the impeller into the trough to complete the cleaning effect of gravel.

Performance characteristics

Wheeled sand washing machine features:

1, bucket sand washing machine structure is simple, impeller drive bearing device and water and water material isolation greatly avoid the bearing due to flooding, sand and contaminants cause damage to the phenomenon, greatly reduce the accident rate.

2, fine sand and stone powder loss is very little, the construction of sand grading and fineness modulus to meet the standard requirements. Wheel-type sand washing machine in addition to the screen almost no wearing parts, with long life, long-term maintenance.

3, sand and gravel washing machine repair convenience, handling capacity, power consumption, high degree of cleanliness. The new sealing structure, the whole block oil bath drive, adjustable overflow weir plate to ensure that the series of products efficient, durable, cleaning, dehydration effect is good, fine products remain chaotic and so on.

product description

The bucket sand washing machine has a high degree of cleaning, reasonable structure, large output, less sand loss during sand washing, especially its transmission parts are separated from water and sand, and the failure rate of wheeled sand washing machine is much lower than that of common sand washing Machine, is the domestic sand washing industry to upgrade the best choice.

For the sand production line, sand making machine, sand washing machine, shaker, feeder, crusher, is essential for sanding products.

Sand sand machine with advanced technology, sand washing machine combined with the actual situation of domestic sand and gravel industry developed efficient sand washing equipment, sand washing machine with a clean height, reasonable structure, large output, sand washing machine sand washing process less sand, especially Its transmission parts are with water, sand isolation so the failure rate is much lower than the commonly used sand washing machine, sand washing machine is the best choice for domestic sand washing industry upgrading.

Stone machine safety

Wash stone machine safety, should pay attention to:

1. Wash the stone machine before starting the hand by rotating the rotor, check the machine with or without abnormalities.

2. The use of units should be based on the specific circumstances of the scene, in the V-belt on the installation of protective equipment before they can run. In the case of

3. Washing machine can not be repaired when cleaning and cleaning work, is strictly prohibited boot maintenance. In the case of

4. Do not add more than the required size of the stone.

5. The machine should be rotated in a fixed direction and not in the reverse direction.

6. When the machine is running, if there is abnormal vibration or sound, should immediately stop feeding, to the box after the material exhausted, immediately stop the motor, stop checking, troubleshooting, to continue to run. In case of emergency first stop the motor, before the boot must clear the cavity material, no load start. In the case of

7. Washing machine workplace should not be stacked debris, and must have enough light of the lighting equipment.

Installation and maintenance

Maintenance of the machine is an extremely important regular work, it should be extremely operational and maintenance and other closely with the full-time staff should be on duty inspection.

Washing machine installation

1, the equipment should be installed on the basis of the level of concrete, with anchor bolts.

2, the installation should pay attention to the main body and horizontal vertical.

3, after installation, check the various parts of the bolt without loosening and whether the mainframe door fastening, if any fastening.

4, according to the power of the device configuration power lines and control switches.

5, check is completed, the empty load test, the test can be normal production.

Washing machine maintenance

1, the bearing bear the full load of the machine, so good lubrication on the bearing life has a great relationship, it directly affects the machine life and operating rate, which requires the injection of lubricants must be clean, the seal must be good, the machine Main oiling (1) Rotary bearings (2) Roll bearings (3) All gears (4) Movable bearings, sliding surfaces.

2, the new installation of the wheel prone to loose must be regularly checked.

3, pay attention to the work of the various parts of the machine is normal.

4, pay attention to check the wear parts of the wear and tear, pay attention to replace the wear parts.

5, put the activities of the chassis plane, should be out of dust and other objects in order to avoid the machine can not break the material when the activities of the bearings can not move on the chassis, resulting in serious accidents.

6, bearing oil temperature rise, should immediately stop the cause of the check to be eliminated.

7, rotating gear in the operation if the impact should immediately stop the inspection and eliminate.

Product Application:

Sand washing machine is widely used in gravel field, mining, building materials, transportation, chemical, water conservancy and hydropower, concrete mixing plant and other industries in the material washing.

Product specifications and technical parameters:

specification | XS2200 | XS2600 | XS2900 | XS3500 |

Wheel diameter(mm) | 2200 | 2600 | 2900 | 3500 |

Rotating speed(r/min) | 1-2 | 1-2 | 0.8-1.5 | 0.8-1.2 |

Processing capacity (t/h) | 15-30 | 20-50 | 50-100 | 120-200 |

Motor Power(kw) | 4 | 5.5 | 7.5 | 11 |

total weight(kg) | 4300 | 5600 | 8100 | 9900 |

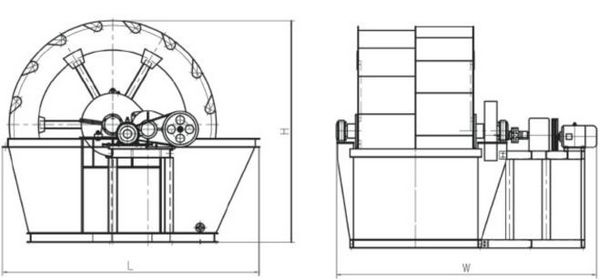

Dimensions (L×W×H)(mm) | 3150×1910×2280 | 3520×2390×2690 | 3820×2640×3200 | 4420×2930×3800 |