Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

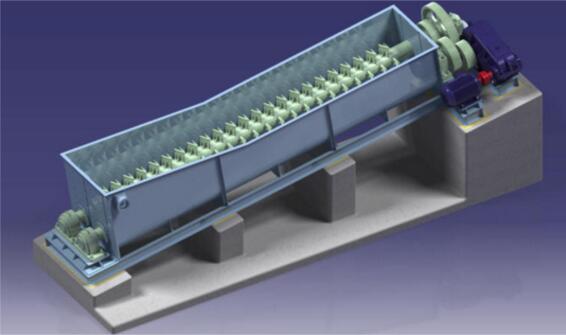

Washing machine is divided into single-screw washing machine and double helix washing machine.

Spiral tank type washing machine for black and nonferrous metallurgical mines and other pre-selected ore, the ore washed with water to remove the ore in the mud and other impurities, so that the ore to the process and economic requirements, widely used in manganese ore Selection and selection, especially in the soil in the particles of manganese ore the best results. Its ability to deal with the larger is to meet the large productivity of the ore, stone cleanliness requirements of the enterprise's ideal equipment.

Product structure and principle:

The main structure of the spiral concentrator:

Trough, reducer, motor, center axis, spiral blade, bracket composition. Bracket welding on the central axis, the spiral blade is installed with bolts, so that the blade does not sag without deformation.

working principle:

Spiral washing machine, spiral stone washing machine with different proportions of solid particles, and thus the speed of settlement in the liquid of different principles, the mechanical classification of the washing equipment. FG series of washing machine for metallurgical, building materials, water and electricity industries such as washing, grading, impurity and other operations, spiral washing machine for granular and coarse-grained material washing operations. Spiral type washing machine with different proportions of solid particles, so the speed of settlement in the liquid of different principles, the mechanical classification of the washing equipment.

Spiral washing machine is the use of water buoyancy effect, the dust and impurities in the sand separation. Through the spiral of the agitation, to filter to impurities, to enhance the purpose of transport. And in the promotion process, also carried out mixing work. Is the sand to stir evenly, no fine, coarse sand of the points.

Spiral washing machine with a long spiral, sealing system is good, simple structure, processing capacity, easy maintenance. Sanding water content, low mud content. Widely used in a variety of ore mining industry.

The main operation of the washing machine:

Washing machine for construction sites, gravel plants, concrete prefabricated plants and hydropower sites with a large number of sand and gravel operations, can also be used for the ore washing, grading, dehydration. The washing can be carried out in a scrubber or in a sieving and grading apparatus.

Installation, commissioning and commissioning:

1. After the washing machine to be shipped, the use of units should immediately check the parts are complete, with or without damage. Make sure the machine is intact before installation. 2. The use of units should be in accordance with the specific circumstances of the scene, the design of the basic construction of the washing machine, the washing machine can be installed on a solid solid foundation. 3. The installation must be installed in accordance with the requirements of the installation diagram to ensure that the tilt angle. 4. The motor is mounted on the rails to adjust the tightness of the belt. The pulleys and motor pulleys should be parallel to the installation. 5. Adjusted according to the above requirements, the rotor will turn a few turn to check whether the jammed, collision phenomenon.

Spiral stone washing machine empty load test run:

1. After the motor starts, the machine should be running smoothly, without any normal vibration.

2. The bearing temperature does not exceed 35 ℃.

3. Air run time 2-4 hours, after the test machine, check whether the connection is loose, and adjust it.

Spiral stone washing machine load test:

1. In the empty load test run on the basis of good, before the load operation test.

2. Machine operation should be smooth, no normal vibration.

3. The bearing temperature does not exceed 40 ℃.

4. Do not allow dust to enter the seal.

5. Determine the actual power of the motor, there must be no abnormal fluctuations.

6. Load operation test for 5-6 hours in a row, when the operation is confirmed as normal and correct, before the official production.

Product Application:

For the selection of gold, tin, tungsten, titanium, hematite, iron ore, coal and other minerals, especially in the field of manganese ore beneficiation has been widely used.

Product specifications and technical parameters:

Types of | Model specifications | Spiral diameter(mm) | Selected particles(mm) | Water ConsumptionT/h | Production capacityT/h | Motor rateKw | Overall size length × width × height(mm) | weightKg |

Light single helix | XL-508 | 508 | ≤10 | 14-88 | 20 | 7.5 | 8000×2343×1530 | 2670 |

XL-610 | 610 | ≤10 | 14-165 | 50 | 7.5 | 8000×2490×1530 | 3800 | |

XL-762 | 762 | ≤10 | 18-124 | 75 | 11-15 | 9070×2650×1638 | 5225 | |

XL-914 | 914 | ≤10 | 18-162 | 100 | 11-15 | 9070×2650×1638 | 6370 | |

XL-1118 | 1118 | ≤10 | 27-333 | 175 | 30 | 9070×2830×1900 | 9800 | |

Light double helix | 2XL-762 | 762 | ≤10 | 40-250 | 140 | 2×11 | 11580×3965×2370 | 7440 |

2XL-914 | 914 | ≤10 | 105-620 | 200 | 215 | 9070×3300×1638 | 9531 | |

2XL-1118 | 1118 | ≤10 | 125-1400 | 350 | 222 | 9070×3890×1900 | 16700 | |

Heavy single helix | XLZ-762 | 762 | ≤60 | 355-450 | 80-125 | 22 | 11580×5226×2370 | 9800 |

XLZ-914 | 914 | ≤60 | 400-600 | 125-175 | 30 | 6980×1200×1340 | 11800 | |

XLZ-1118 | 1118 | ≤75 | 500-750 | 180-250 | 37 | 7400×1380×1950 | 13900 | |

Heavy double helix | 2XLZ-762 | 762 | ≤60 | 600-800 | 100-150 | 2×22 | 6980×2091×1340 | 16800 |

2XLZ-914 | 914 | ≤60 | 700-900 | 150-200 | 2×30 | 7120×2146×1590 | 20800 | |

2XLZ-1118 | 1118 | ≤75 | 900-1100 | 200-300 | 2×37 | 8500×2861×2150 | 23870 |