Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

It is an efficient sedimentation enrichment (grading) equipment developed by the factory on the basis of summarizing the working principle, characteristics and shallow settlement theory of the traditional peripheral (center) transmission type thickener. The equipment is small, small footprint, no power, less investment, the use of low cost, high settlement settlement rate. Suitable for precious metal concentrator, building materials, chemical and other industries of sewage treatment: in recent years has been tungsten, tin and other rare precious metal concentrator widely used.

Product structure and principle:

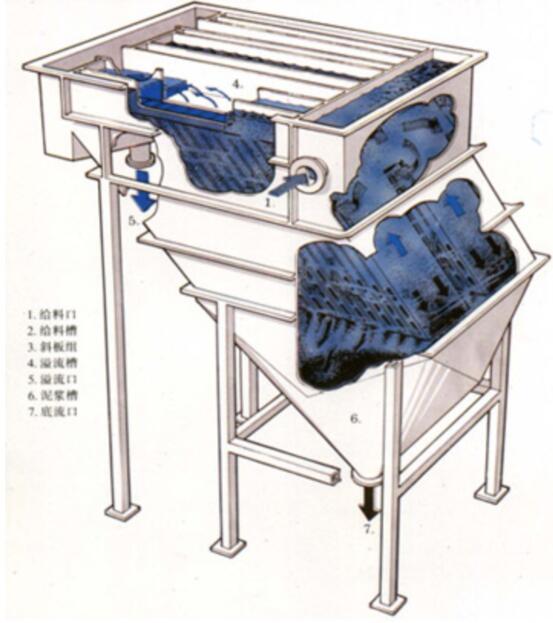

Inclined tube thickening machine is a high efficiency sedimentation (grading) equipment developed by our factory on the basis of summarizing the working principle, characteristics and shallow settlement theory of the traditional peripheral (center) transmission type thickener. The introduction of foreign aircraft series of products, using a new mechanical structure, to strengthen the flocculant solid particles on the role of aggregation, which mainly includes flocculant addition system, overflow slot. But also lengthened the center discharge tube, in order to shorten the dispersion of solid particles distance, enhance the dense effect. With no power, no energy consumption characteristics.

The slurry or other treatment liquid from the feed area into the sedimentation concentrated area, in this area to form a relatively dynamic balance of the suspension process, the larger particle size of the particles, due to its faster sedimentation speed, in order to overcome the water pulse force and precipitation Of the smaller particles with the rising water flow into the ramp area. The slanting zone is filled with hexagonal thin-walled inclined pipe at an angle, and the water flow is divided into many precipitation units. The fine particles entering the inclined pipe area reach the inclined pipe wall under the laminar hydraulic settlement and accumulate to a certain amount. Under the action of gravity down to the settlement area, according to the separation of particle size processing capacity design requirements, failed in the inclined section of the fine particles, will be discharged with the overflow, in order to achieve the classification and precipitation process.

Can be achieved on the equipment to achieve classification, enrichment of the recovery of metal minerals or concentrated emissions to reduce the amount of sewage and water recycling and other functions, change the equipment do not power, the sedimentation overflow overflow water can reach the standard discharge, recycling Mine sewage emissions of 60-80%.

Oblique thickener Product principle:

The liquid through the feed port after mixing into the dense machine, in the cohesion and gravity under the dual role, with the continuous feeding of materials, most of the overflow in the upper part of the body through the overflow tank to the end of the overflow and small Part of the overflow in the middle of the body in the settlement of the formation of small vortex in the lower part of the body of the compression zone, the sediment in the solid particles under the action of gravity compression, while causing the liquid upward movement, compressed concentrate from the lower bottom tube The

Inclined plate thick machine Features:

The box-type swash plate thickener machine includes the upper case and the lower cone. The swash plate group is composed of a number of independent swash plate units. The treated material enters from the lower end of the swash plate unit, and the overflow is above the full length of the swash plate group. Slot, slot at the end of the opening of the orifice, resulting in overflowing hydraulic back pressure to ensure that the ramp plate unit load uniform to prevent radial turbulence.

1, small size, small footprint, construction and purchase cost is low, covers an area equivalent to the old dense pool of 1/12 and 1/20, the purchase cost is only one-half.

2, advanced technology and high efficiency. Can be achieved in the equipment classification, enrichment of the recovery of metal minerals or concentrated emissions to reduce sewage discharge and water recycling and other functions.

3, energy-saving emission reduction effect is good. The equipment without power, saving energy consumption, and by sedimentation overflow overflow water can reach the standard discharge, recycling, reduce the discharge of sewage discharged 60% -80%.

4, efficient energy-saving, easy installation, flexible configuration, good control of the characteristics.

Product Application:

In addition to the ordinary vibrating screen with a variety of excellent performance and role of the vibrating screen, the dehydration sieve with a thicker machine for tailings dry row, is the best dehydration sieve and tailings dry equipment.

2, the professional design of high-frequency, low amplitude, low power consumption, more suitable for 24 hours continuous dry row of operations; 3, the production of high-frequency, low power consumption, 4, high wear-resistant sieve plate long life, modular splicing assembly design, easy to replace; 5, high-pressure sieve, The steel frame is composed of the main body of the frame, which can effectively extend the service life of continuous operation.

Tailings dry row of screens are also suitable for: tailings dry row treatment, slime dehydration is not, washed quartz sand, mud dehydration and other technical aspects.

Product specifications and technical parameters:

Model specifications | Dimensions (mm) (L / W / H) | Concentrated pulp (24h) | Water recovery (24h) |

TY-5㎡(Single bucket) | 3580/2350/3500 | 300-800t/d | 500-1000t/d |

TY-10㎡(Double bucket) | 7160/2350/3500 | 500-1500t/d | 1000-1500t/d |