Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Tailings dry row of special sieve, also known as dehydration sieve. Is my company tailor dewatering professional development of the tailings dry system equipment. 2, high wear-resistant polyurethane sieve or high-strength composite screen filter surface, V-type design of high-frequency, low-amplitude, low-power power source; 2, high wear-resistant polyurethane sieve or high-strength composite screen filter surface, V-type design Module assembly form filter fine tailings sand filter layer; 3, steel components welded pipe rack combination of the sieve machine tray; 4, dehydration screen with large vertebral volume warehouse design efficient concentrated cyclone, composed of tail Mine dry system.

In addition to the ordinary dehydration sieve with a variety of excellent performance and role, the tailings dry row sieve with thicker for tailings dry row, is the best dehydration sieve and tailings dry equipment.

Product structure and principle:

Do you still worry about the annual use of thousands of tons of fine sand slime can not reasonably use it? Do you still have a headache for the high cost of fine sand slime recovery equipment? High-service fine sand, slime dewatering screen professional for you to solve the fine sand, slime recovery problems.

With the development of China's coal industry, coal washing rate increased year by year, as a coal washing process in the waste - slime, a large backlog, has become a major public hazard. According to statistics, China's existing sand washing, coal preparation plant annual production of nearly 10 million tons of sand, slime, and the utilization rate of only 30%.

So Jiedeng Mining Equipment Manufacturing Co., Ltd. design and production of fine sand, slime dewatering screen stand out, the machine is my company for the slurry material dehydration, disengagement, deslimatization of a screening equipment. Because of its screen trajectory similar to the straight line, also known as linear vibration dehydration sieve, and because it is often used coal preparation plant coal recovery, can also be called slime dewatering sieve.

Jiedeng fine sand slime dewatering sieve features:

(1) screen box trajectory as a straight line, the relative energy consumption less, high dehydration, installation and transfer convenience, easy to replace.

(2) high-speed coal slime dehydration sieve power unit has a common motor driven by the coupling exciter drive and vibration motor drive {smaller model) two forms.

(3) high-quality coal slime dehydration sieve surface with nylon, stainless steel and polyurethane and other materials, can be combined with the actual situation of materials and users to choose.

(4) Sieve surface V-type design, higher dehydration efficiency.

Prior to the coal preparation plant for the recovery of slime, the use of complex systems, high power consumption of the disk vacuum filter, one-time investment in expensive plate and frame filter press and sedimentation centrifuge and flocculant performance requirements, the use of Large belt extruder and so on. Overall investment, maintenance costs are high.

Now the use of dehydration plant design process behind, the use of a long time, low production efficiency, resulting in the production process in the frequent failure, resulting in system downtime and output of coal water content fluctuations exceeded, whirlpool can not be normal Running, affecting the effect of dehydration.

Jiedeng slime dewatering sieve Working principle:

High-quality coal slime dewatering screen using a two-electrode self-synchronization technology, general-purpose eccentric block, adjustable amplitude vibrator. Mainly by the screen box, exciter, support system and motor components. Through the tape joint drive two separate non-contact vibrator for synchronous reverse operation, the two sets of eccentricity generated by the centrifugal force along the vibration direction of the component superposition, reverse centrifugal offset, thus forming a single vibration along the vibration direction , So that the screen box for reciprocating linear motion. Sieve box sieve from the feed port to the outlet was negative angle installation, so that the liquid material in the sieve plate to do climbing movement, coupled with vibration, so as to achieve the effect of dehydration.

Slime dewatering screen to the coal preparation plant in the future production process is more reasonable, clean coal production, quality indicators to a new level plays a very important role for the coal preparation plant safety work has played a strong role in promoting, marking the Coal preparation plant quality of coal products has opened a new page.

The slime dewatering screen is an important equipment of the coal preparation plant production system. It plays a key role in the dehydration effect of the main product and the normal operation of the downstream production process. Its stable operation directly affects the production quality of the clean coal. High-frequency dehydration screen compared to other washing equipment is concerned, the biggest feature is the low cost of investment, high rate of return, according to an annual output of 10,000 tons of dry slime recommended that the annual value of 1.5 million yuan can produce!

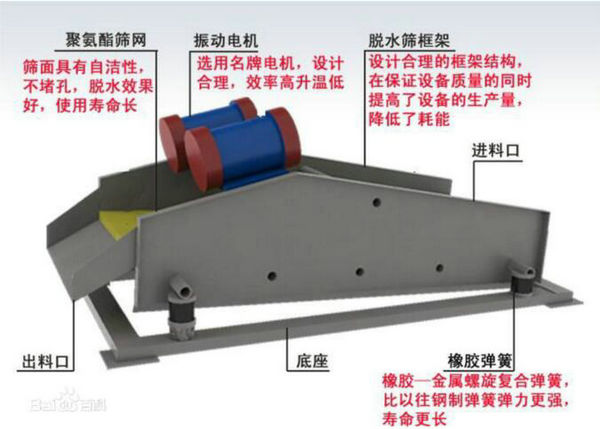

First, the tailings dry row (dehydration sieve) sieve structure:

Tailings dry row of screens by the screen box, support device (base), motor rack, vibrator, universal shaft, tape coupling, motor and other components.

Second, tailings dry row (dehydration screen) Screen principle:

The feed tailings are fed evenly from the feed tank to the inlet of the sieve. First, about 1/3 of the moisture is removed at a level of 45 ° to install the drain sieve, and the combination of the sieve and the sieve Department of the emergence of the accumulation of materials, slime particles by gravity settlement, began to form a thin filter layer, filter layer and prevent the remaining particles through the screen, making the filter layer gradually thickening. Water can not be screened in the upper part of the filter layer to form a pool, because the filter layer is thin, water gradually in the strong movement gradually removed, due to high frequency and low amplitude vibration state, making the formation of filter tail More and more dense, to the discharge mouth, the material to form a cake, the tailings of water in addition to part of the removal from the screen surface, the rest due to capillary action surfaced in the material layer, due to the negative surface of the screen installation, Will overflow from the discharge port, the surface of the water will flow to the junction of the pool.

Third, the tailings dry row (dehydration screen) Screen technical characteristics:

1, high operating frequency, high vibration strength, low moisture content on the screen, the unit handling capacity is high, when used for tailings dehydration can get a higher solid recovery rate.

2, the use of self-synchronization principle, the motor through the tire coupling drive vibrator, simple structure, low noise.

3, the negative angle of the installation, to the dehydration section of the screen surface and the level of 45 degrees to install, increase the area of dehydration and promote the material as soon as possible to form a filter layer of dehydration.

4, in order to adapt to the different nature of different tailings, the sieve amplitude adjustable, the method is to adjust the main and vice eccentric block angle, so as to meet the different nature of tailings

Dehydration effect, make the best efforts to achieve the best process results.

5, side plate and beam connection using torsional shear type high strength bolts, no weld, to avoid the welding stress caused by the side plate cracking problem.

6, the vibrator for the block eccentric unit body structure, easy disassembly and maintenance.

7, bearing the use of vibration equipment for bearings, to avoid premature bearing damage.

8, the screen surface with polyurethane flexible screen surface, high opening rate and flexibility, is conducive to dehydration.

9, the screen side of the pressure plate are used polyurethane materials, long life, the screen surface fixed and reliable, and can effectively protect the screen frame side plate from the material erosion.

10, the screen surface with rail seat installation, can be very convenient for the screen surface maintenance and replacement.

11, the lower beam surface coated with anti-wear coating, to prevent premature wear and broken beam.

12, the use of steel coil spring vibration, the maximum reduction of the machine on the basis of the dynamic load.

13, using the finite element structure analysis software to ensure that the screen frame strength, stiffness and force is reasonable, and light weight, minimum energy consumption.

14, according to the user can be equipped with a chassis and feeding box structure, easy installation and commissioning.

Installation and maintenance:

Pre-installation preparation

⒈ check whether the motor signs and requirements in line.

⒉ measured with 500 V megger in the insulation resistance, the value of the stator winding should be dry, the drying temperature can not exceed 120 ℃.

⒊ check the motor fasteners, beware of loosening.

⒋ check the motor surface with or without damage, deformation.

⒌ check whether the rotation is flexible, if abnormal, should be excluded.

⒍ check the power, whether the lack of phase, and no-load operation for 5 minutes.

Installation and adjustment

⒈ motor should be fastened to the installation surface, the installation surface must be smooth, smooth.

⒉ motor can be installed horizontally.

⒊ motor leads with four-core rubber cable YZ-500V, then the power cable leads to the cable does not allow a sharp fold, and the vibration with a reliable fixed.

⒋ motor should have a reliable grounding, the motor has a grounding device, the terminal has a sign, can also use the foot bolts bolts ground.

⒌ exciting force adjustment.

Use and repair

⒈ The machine should be equipped with electrical protection device.

⒉ initial operation of the machine at least once a day to check the anchor bolts to prevent loosening.

⒊ When the motor rotation direction does not meet the requirements, adjust the power phase sequence can be.

⒋ motor should ensure good lubrication, each running about two weeks to add lithium-based grease (ZL-3) once, when refueling, through the oil cup by adding the amount of lithium grease. When a sealed bearing is used, the motor is not fitted with an oil cup.

⒌ the cumulative operation of the machine after 1500 hours, should check the bearing, if serious damage should be replaced immediately.

⒍ the machine will be used for a long time after the re-use, should measure the insulation resistance, for 500 volts megger measurement, should be greater than 0.5 megohms.

Daily maintenance

⒈ before the start:

⑴ check the thick mesh and fine network with or without damage

⑵ Check whether the transport support is removed.

⒉ start when:

⑴ pay attention to whether the abnormal noise

⑵ current is stable

⑶ vibration with or without abnormalities

⒊ after use: clean up every time you use it.

Regular maintenance

Regular inspection of coarse mesh, fine mesh and spring with or without fatigue and damage, the body parts are damaged due to vibration, the need to add the oil parts must be lubricated.

Precautions for use:

After the test run, check the above correct, re-tighten all the fasteners, screens and parts fastened intact, you can formally use. Before doing so, you must do the following:

1) The training of the operator should understand the structure of the equipment and the simple working principle; before work, should be ready to drive, check the rotary parts flexible without jamming, the screen intact, the parts without loosening, bolt fastening.

2) no load start and stop the vibrating screen are generally used for crushing screening equipment or washing process, requiring the sieve machine no load start and stop. So the need to comply with the reverse process start, along the principle of the process of parking. Except for special reasons, no material parking is allowed. When there is material on the screen surface, you must clear it before you start. After normal operation, we can start feeding.

Product Application:

Dehydration screen with a variety of ordinary vibrating screen with a variety of excellent performance and role, the dehydration sieve with a thicker machine tailings dry row, is the best dehydration sieve and tailings dry equipment.

2, the professional design of high-frequency, low amplitude, low power consumption, more suitable for 24 hours continuous dry row of operations; 3, the production of high-frequency, low power consumption, 4, high wear-resistant sieve plate long life, modular splicing assembly design, easy to replace; 5, high-pressure sieve, The steel frame is composed of the main body of the frame, which can effectively extend the service life of continuous operation.

Tailings dry row of screens are also suitable for: tailings dry row treatment, slime dehydration is not, washed quartz sand, mud dehydration and other technical aspects.

Product specifications and technical parameters:

model | Screen area㎡ | power(kw) | Processing capacity(m³/h) | Feed size(mm) | weight(t) | Dimensionsmm |

TS0820 | 1.5 | 0.75×2 | 5-10 | ≤10 | 0.8 | 2300*1000*750 |

TS0920 | 1.8 | 1.1×2 | 10-20 | ≤10 | 1.2 | 2300*1200*750 |

TS1020 | 2 | 1.5×2 | 20-30 | ≤10 | 1.6 | 2300*1300*750 |

TS1225 | 3 | 2.2×2 | 50-80 | ≤10 | 2.1 | 2800*1500*800 |

TS1530 | 4.5 | 3×2 | 100-120 | ≤10 | 3.2 | 3300*1800*800 |