Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Custom center vibrating screen for the ore and coal and other materials in the coarse, fine, very fine at all levels of screening. Can also be used for the material for dewatering, off the media and other treatment. Self-centering vibrating screen structure mainly by the screen box, exciter, suspension (or support) devices and motors and other components. The motor is driven by the triangular belt to drive the spindle of the exciter, and the screen box is vibrated due to the centrifugal inertial force of the unbalanced creature on the exciter. Change the eccentricity of the exciter, or obtain different amplitudes.

Product structure and principle:

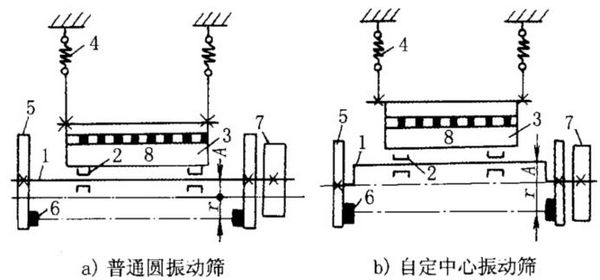

1. Spindle 2. Bearing 3. Screen box 4. Suspender spring 5. Disc 6. Eccentric block 7. With pulley 8. Screen

It can be seen from the figure that the difference between the ordinary circular vibrating screen and the self-centering vibrating screen lies only in that the structure of the vibrator is slightly different. The center of the bearing is located on the same straight line as the center of the pulley. When the vibrating screen is running, With the screen box with vibration, resulting in repeated stretching of the V-belt makes it easy to damage, and the need to use a smaller amplitude (usually less than 3mm). Due to these shortcomings, this vibrating screen has been rarely used. The center of the pulley of the centering vibrating screen is located between the center of the bearing and the center of gravity of the eccentric block and the centerline of the pulley is located on the center of gravity of the eccentric block and the vibrating body. Therefore, when the vibrating screen is in operation, Screen box with vibration, only for rotary motion, which can be used to increase the amplitude to improve the efficiency of screening. Thus the custom center vibrating sieve developed rapidly and gained a wide range of applications. At present, the circular shaker used in industrial production generally belongs to the type of custom center sieve.

Mainly by the screen box, exciter, suspension (or support) devices and motors and other components. The motor is driven by the triangular belt to drive the spindle of the exciter, and the screen box is vibrated due to the centrifugal inertial force of the unbalanced weight on the exciter. Change the exciter eccentric weight, can get different amplitude.

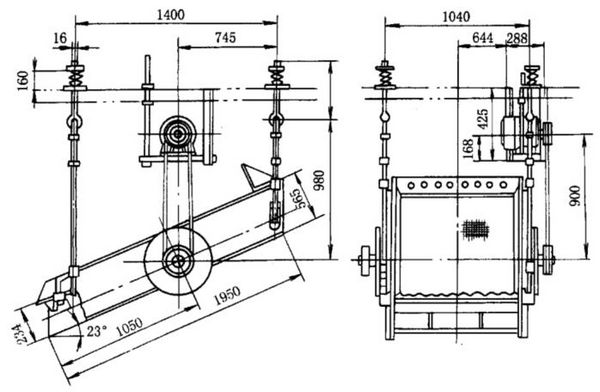

SZZ 900 * 1800 hanging vibrating screen

Principle of hanging vibrating screen

The vibrating screen is mainly divided into linear vibrating screen, circular vibrating screen and circular vibrating screen. The circular vibrating screen is circular motion, and it is a kind of multi-layer and high efficiency new type vibrating screen. Circular vibrating screen with cylindrical eccentric shaft exciter and offset block amplitude adjustment, material sieving line length, screening specifications, is designed specifically for the quarry sieve material design, but also for mining, coal preparation, mineral processing , Building materials, power and chemical sector for product classification, with a reliable structure, strong excitement, high screening efficiency, vibration and noise, durable, easy maintenance, the use of security and so on.

The circular vibrating screen is a kind of high efficiency vibrating screen. Suitable for quarry screening sand and gravel material, but also for coal preparation, mineral processing, building materials, electricity and chemical industries for product classification.

Scope: Widely used in building materials, metallurgy, chemical, road and bridge, mining and other materials screening.

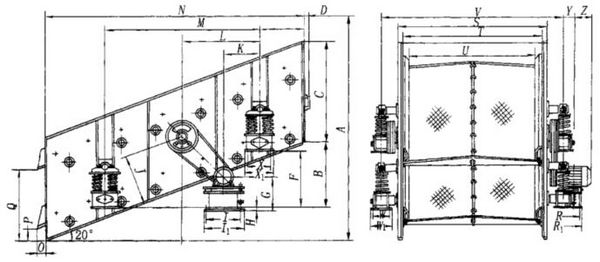

SZZ seat vibrating screen

Seat vibrating screen works:

The vibrating screen is mainly divided into linear vibrating screen, circular vibrating screen and circular vibrating screen. The circular vibrating screen is circular motion, and it is a kind of multi-layer and high efficiency new type vibrating screen. Circular vibrating screen with cylindrical eccentric shaft exciter and offset block amplitude adjustment, material sieving line length, screening specifications, is designed specifically for the quarry sieve material design, but also for mining, coal preparation, mineral processing , Building materials, power and chemical sector for product classification, with a reliable structure, strong excitement, high screening efficiency, vibration and noise, durable, easy maintenance, the use of security and so on.

Self-centered vibrating screen is a kind of efficient vibrating screen. Suitable for quarry screening sand and gravel material, but also for coal preparation, mineral processing, building materials, electricity and chemical industries for product classification.

Self - centering vibrating screen structure

(1) ring groove rivet connection, advanced structure, durable;

(2) the use of eccentric exciter, flexible connection, smooth operation;

(3) mining sieve beams and sieve box with high strength bolts, simple structure, easy maintenance;

(4) advanced structure, the use of block eccentricity as the exciting force, strong excitement, low power consumption, low noise;

(5) the use of small amplitude, high frequency, large angle structure, so that the machine screening efficiency, the largest processing;

(6) vibrator with large clearance bearings, thin oil lubrication, low noise, long life. The other parts of the versatility, easy maintenance.

Custom center shaker product advantages

(1) due to the strong vibration of the screen box, reducing the phenomenon of material clogging holes, so that the screen has a high screening efficiency and productivity;

(2) simple structure, easy to replace the screen surface;

(3) Screening per ton of material consumed less energy;

(4) Because the pulley center line and the bearing centerline are not on the same straight line, it is possible to eliminate the vibration of the belt and reduce the fatigue and wear of the belt, thereby increasing the amplitude of the sieve and further improving the productivity.

Product Application:

Custom center vibrating screen for the ore and coal and other materials in the coarse, fine, very fine at all levels of screening. Can also be used for the material for dewatering, off the media and other treatment.

Scope: Widely used in building materials, metallurgy, chemical, road and bridge, mining and other materials screening.

Product specifications and technical parameters:

Model | Number of screen layers | Maximum feed size (mm) | Sieve size (mm) | Double vibration(mm) | Production capacity(t/h) | Vibration time (Times/mm) | inclination (°) | Motor Power(W) | DimensionsL*W*H | weight (kg) |

SZZ600×1200 | 1 | 40 | 1-25 | 6 | 10-20 | 1000 | 15-25 | 2.2 | 1370×890×330 | 340 |

SZZ2600×1200 | 2 | 40 | 1-25 | 6 | 10-20 | 1000 | 15-25 | 2.2 | 1370×890×430 | 360 |

SZZ900×1800 | 1 | 40 | 1-25 | 6 | 20-25 | 1000 | 15-25 | 2.2 | 2150×1358×575 | 550 |

SZZ2900×1800 | 2 | 40 | 1-25 | 6 | 20-30 | 1000 | 15-25 | 3 | 2489×1358×770 | 620 |

SZZ1250×2500 | 1 | 100 | 5-40 | 2-7 | 150 | 850 | 15-20 | 5.5 | 2762×1714×680 | 1100 |

SZZ21250×2500 | 2 | 150 | 5-40 | 2-7 | 150 | 850 | 15-20 | 5.5 | 2702×1714×740 | 1300 |

SZZ1500×3000 | 1 | 100 | 1-40 | 8 | 220 | 800 | 15-25 | 7.5 | 3320×1449×787 | 2100 |