Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

GX screw conveyor is widely used in chemical, building materials, food, metallurgy, mining and other departments of a screw conveyor equipment, mainly for the delivery of powder, particle size and small pieces of material. Standard spiral diameter: 150mm; 200mm; 250mm; 300mm; 400mm; 500mm; 600mm.

GX screw conveyor compared with other transportation equipment, with a simple structure, small cross-sectional size, good sealing performance characteristics, the middle of the multi-point loading and unloading, safe and convenient operation and low manufacturing costs. Equipment shortcomings are more serious wear and tear, the amount of delivery than the belt machine is low, the power consumption and the material in the transport process is easy to be broken.

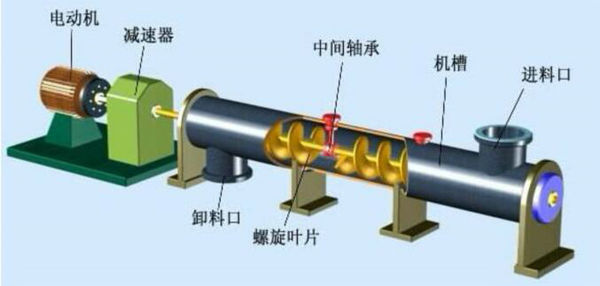

Product structure and principle:

GX series of screw conveyor main features and working principle:

1. Carrying capacity, safe and reliable.

2. Adaptability, easy installation and maintenance, long life.

3. Machine small size, high speed, to ensure fast and uniform delivery.

4. Sealing is good, the shell is made of seamless steel pipe, the end of the flange with each other to connect into one, good rigidity.

GX screw conveyor is a stereotypes product. Spiral diameter has seven specifications, captain 3 ~ 70m, grade difference 0.5m. Can be in the ambient temperature -20 ~ 50 degrees under the conditions of less than 20 degrees of unidirectional transport temperature of less than 200 degrees of material. GX type screw conveyor according to the structure can be divided into the first section, the middle section, tail section three parts. Each part can be divided into several different lengths, according to the different output to send length can be composed of a complete conveyor.

installation method

GX screw conveyor installation structure can be divided into the first section, the middle section, and the tail section of three parts. These three parts are based on user needs to set the length, thus forming a complete GX screw conveyor. If the level of fixed on the ground, the ground need to reserve the foot and the expansion of the hole for the fixed. In the case of angle transmission, it is necessary to set the corresponding support in advance.

GX screw conveyor according to the drive device is also divided into two different ways: right and left installed. Right-mounted - standing on the motor tail part forward, reducer low speed shaft on the right side of the motor;

LS type screw conveyor and GX type screw conveyor difference:

LS-type screw conveyor is the use of rotating spiral will be transported along the fixed material within the shell to carry the transfer work, the head and tail bearings moved to the shell, the use of sliding bearings with a sliding bearing dust seal, General use of powder metallurgy, conveying cement using blankets bearing pad, hanging shaft and screw shaft using slider connection.

LS-type screw conveyor performance characteristics:

1. Carrying capacity, safe and reliable.

2. Adaptability, easy installation and maintenance, long life.

3. Machine small size, high speed, to ensure fast and uniform delivery.

4. The discharge end with a cleaning device, the whole low noise, strong adaptability, access to the material position is flexible.

5. Seal is good, the shell is made of seamless steel pipe, the end of the flange with each other to connect into one, good rigidity. GX tube screw conveyor is the use of rotating spiral will be transported along the fixed material within the shell to complete the transfer of work. Head and tail bearings moved to the outside of the shell, the use of sliding bearings with sliding bearings with dust seal, the general use of powder metallurgy, cement transmission blankets with blankets, hanging shaft and screw shaft with a slider connection.

GX tube screw conveyor is not suitable for conveying perishable, viscous, easy to agglomerate material, these materials will be wrapped in the spiral on the transfer, and then spin without moving forward or in the hanging bearing at the formation of materials Of the plug, leaving the screw conveyor can not work properly. Spiral diameter from 200 mm to 500 mm, a total of five specifications, the length from 2 to 70 meters, the selection of the standard length of the standard, the special needs can be made in the optional section.

GX tube screw conveyor Features:

(1) small size, high speed, to ensure fast and uniform delivery.

(2) good rigidity, good seal. Shell made of seamless steel pipe, the end of the flange connected into one.

(3) the discharge end with a cleaning device, the whole low noise, strong adaptability, access to the mouth position flexible.

(4) carrying heavy weight, safe and reliable.

(5) adaptability, easy installation and maintenance, long life.

Product Application:

GX screw conveyor suitable for conveying small particle size and powder material, not suitable for conveying perishable, sticky and easy to agglomerate the material. Operating temperature is -20 ℃ -50 ℃. The conveying angle is not more than 20 °, the conveying material temperature is 200 ° or less, and the length is 3-70 m. GX screw conveyor is the original mechanical parts stereotypes products, machine reliability, long life, good adaptability, easy installation and maintenance. GX screw conveyor is widely used in building materials, chemical, power, metallurgy, coal, grain and other industries, used in horizontal or inclined transport powder, granular and small pieces of materials, such as coal ash, cinder, cement, food and other materials.

Product specifications and technical parameters:

Spiral straight(mm) | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

Pitch(mm) | 150 | 200 | 250 | 300 | 355 | 400 | 450 |

Rotating speedr/min | 112 | 100 | 90 | 80 | 71 | 63 | 50 |

8 | 14 | 24 | 34 | 64 | 100 | 145 | |

Rotating speedr/min | 90 | 80 | 71 | 63 | 56 | 50 | 40 |

7 | 12 | 20 | 26 | 52 | 80 | 116 | |

Rotating speedr/minDelivery quantitym3/h | 71 | 63 | 56 | 50 | 45 | 40 | 32 |

6 | 10 | 16 | 21 | 41 | 64 | 94 | |

Rotating speedr/min | 50 | 50 | 45 | 40 | 36 | 32 | 25 |

4 | 7 | 13 | 16 | 34 | 52 | 80 |