Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Although the advent of cone crusher than jaw crusher several decades later, but because it can be more than jaw crusher products and more widely used. It is mainly used for a variety of high hardness of the ore in the broken and crushed.

Product structure and principle:

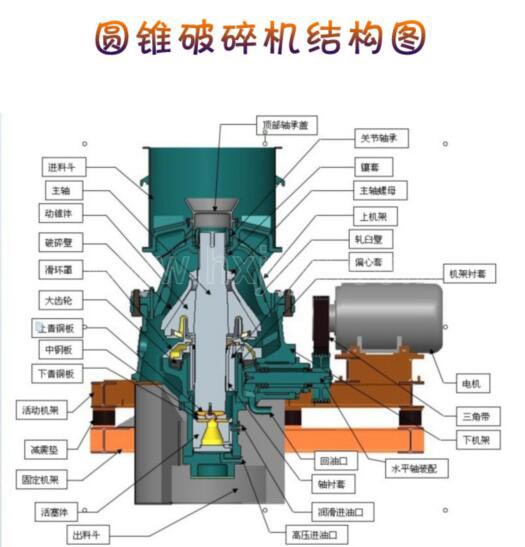

Cone Crusher Structure:

According to the needs of crushing operations, ruthless crusher can be divided into three types

Standard type: mainly used for ore in the broken.

Intermediate type: mainly used in the ore, crushing.

Short head type: mainly used for the fine ore.

According to the adjustment of discharge and overload insurance to different ways to be divided into: spring insurance and hydraulic insurance two types.

Cone crusher working principle:

The working part of the cone crusher is two truncated for the cone, one is the cone 2 (also known as the outer cone), the other is the movable cone 1 (also known as the inner cone). The cone 2 is stationary and is part of the frame. The movable cone 1 is hinged to the O point and its lower end is movably inserted in the eccentric bushing. Therefore, the center axis OO 'of the fixed cone intersects the central axis OO1 of the movable cone bevel. When OO1 rotates around OO ', the moving cone moves along the inner surface of the cone. In the movable cone near the fixed cone of the section, where the material by the dynamic cone of the extrusion, impact and bending effect, as the crushing chamber; in the moving cone from the fixed cone, where the material has been broken under the action of self- Unloaded into the discharge port 3, the material from the feed port 4 into.

In the case of a conical crusher (cone crusher), the rotation of the motor passes through a pulley or coupling, and the drive shaft and the conical part are fixed for a rotary motion around the eccentric sleeve, so that the crusher of the cone crusher Sometimes close and then away from the fixed set in the adjustment of the rolling white wall surface, so that the ore in the crushing chamber continue to be impact, extrusion and bending effect to achieve the ore broken.

Cone crusher working characteristics:

(1) continuous rotation of the moving cone, the material of the crushing process and the discharge process along the work surface alternately continuous, high productivity.

(2) material folder between the two cones, by the extrusion, bending and shear, broken more easily, less power consumption.

(3) product material is more uniform, was cube shape, moving cone work surface wear is more uniform.

(4) structure, cone crusher structure of the main frame, horizontal axis, moving cone, balance wheel, eccentric sets, the broken wall (fixed cone), the next broken wall (moving cone), hydraulic coupling, Lubrication system, hydraulic system, control system and other components.

(5) the movable cone and the fixed cone are positive, moving cone swing, in the crushing chamber near the mouth, moving cone and the fixed cone between the gap is equal to the parallel band, so that the finished material uniformity. The size of the feed port is small, can be processed by the first broken material.

(6)) This series of cone crusher with dry oil or water two sealed way, so that dust impurities can not enter the body, thus ensuring the clean oil cleaning, extending the sliding bearing, thrust ball bearing life, making the machine Reliable operation.

Product Application:

Cone crusher has a very significant performance advantages, such as broken effect, stable performance, reliable, wide range of use, access to the vast number of users unanimously approved. The following we use the industry, materials and in the mobile crushing station, the role of the production line, to detail the use of cone crusher.

Cone crusher

1, the use of industry: cone crusher widely used in metallurgy, mining, building materials, roads, railways, water conservancy, chemicals, cement, construction, refractory materials and ceramics and other industrial sectors.

2, the use of materials: suitable for crushing compressive strength of not more than 320MPa (MPa) of various soft and hard ore, such as river pebbles, rocks (limestone, granite, basalt, diabase, andesite, etc.) Crumbs of artificial sand, etc., and the specific size of the broken pieces of the size of the machine according to the different models will be different, in short, the compressive strength of materials and the maximum block should be consistent with the technical parameters specified in the table.

3, the use of mobile crushing stations: used in mining, coal mines, garbage and construction waste recycling, suitable for earth and stone works, urban infrastructure, roads or construction sites and other operations;

4, the role of the production line: the most common is the use of cone crusher in the stone crusher production line, river pebble crushing production line, mineral material broken production line, industrial milling in the primary broken, quartz sand broken production line, , Construction waste disposal, thermal power plant material handling, iron ore primary crushing, and so on.

Product specifications and technical parameters:

model | Broken cone diameter(mm) | Maximum feed size(mm) | Discharge port width(mm) | Processing capacity(T/H) | Motor Power(kw) | Number of spindle swings(次/m) | weightt) | Dimensions(Long × wide × high) (mm) | |

Type | |||||||||

PYB | 600 | 600 | 65 | 12-25 | 40 | 30 | 356 | 5 | 2234×1370×1675 |

PYD | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | ||||

PYB | 900 | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692×1640×2350 |

PYZ | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | ||||

PYD | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | ||||

PYB | 1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790×1878×2844 |

PYZ | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | ||||

PYD | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | ||||