Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

In the concentrator for the same composition of the grading machine with the grading machine, the need to improve the transport of sand bodies, so this classifier is called mechanical classifier, in fact, the grading process is still by the sedimentation rate of particles The The mechanical classifier is also used for the washing of clay-containing minerals and the de-sludge and dewatering of the ore, in addition to pre-grading and inspection classification as auxiliary equipment for grinding. According to the different forms of transport grit machinery, mechanical classifier can be divided into spiral classifier, rake classifier and float tank classifier. The spiral grading machine is simple in construction and easy to operate. The classification tank has a large inclination angle, which is easy to connect with the grinding machine for self-flow, so the application is more common. Other forms of grading machine in China still have to use, but has stopped manufacturing.

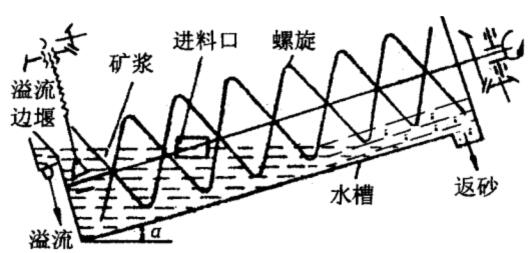

The shape of the spiral classifier is a rectangular chute, slot bottom angle of 12 ° ~ 18.5 °, the bottom was semi-circular. The slot is fitted with 1 or 2 long shafts, and the helical blades are arranged continuously along the shaft length. Rotate the screw shaft with the upper drive mechanism. Such as double helix, from the top of the spiral leaves are turned outward. The pulp is fed by the side of the tank. A subsidence surface is formed in the lower part of the tank. The coarse particles are sank to the bottom of the tank and then discharged by the screw to the top, during transport and dehydrated. The fine particles that are not settling are discharged from the weir by the surface slurry. The grading process is basically the same as in the slime bucket. There is a frame at the bottom of the trough. The upper beam of the frame is provided with a lifting means for adjusting the distance of the helical blade from the bottom of the groove and lifting the screw shaft during parking to prevent the ore from depositing the buried helical blades. Spiral classifier grading level can be divided into high weir and immersion (or sinking) two. The weir of the high weir classifier is higher than the center of the lower end of the screw shaft and below the upper edge of the spiral blade. Graded liquid surface length is not large, the liquid surface can be directly felt the spiral blade agitation effect, it is suitable for coarse grading, grading and more in more than 0.15mm. The lower end of the immersion grading machine is completely immersed below the liquid level, and the grading area is large and stable, which is suitable for fine grading and grading. The grading size is below 0.15mm. Its overflow productivity is higher. In addition there is a low weir type spiral classifier, the classification of liquid level below the bottom of the spiral bearings, the liquid surface is small, stirring effect, mainly for the use of mud and gravel washing.

Product structure and principle:

Main Structure Description:

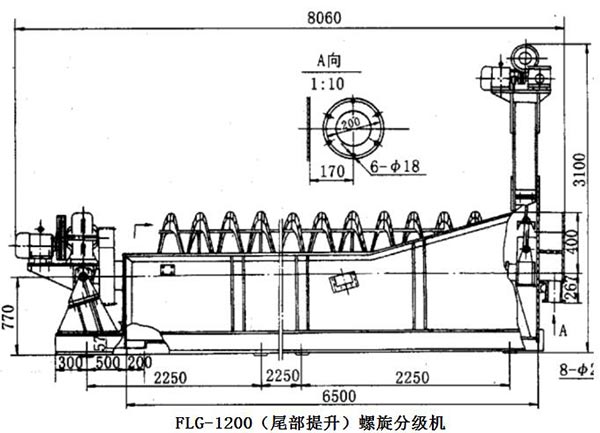

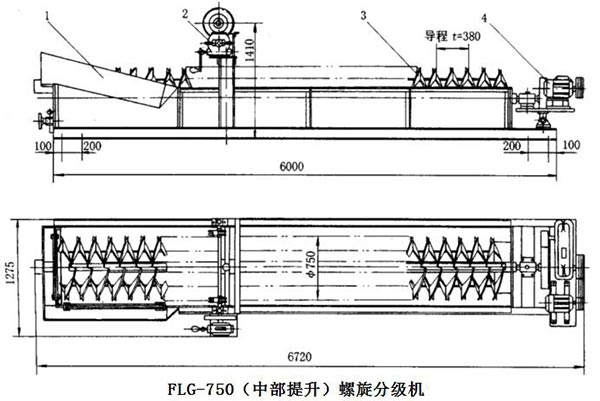

The overall structure of the spiral classifier is divided into: tail lifting and middle lifting two.

The advantages of the central lifting phase in the tail lift are: When the screw classifier in the lifting of the screw shaft or normal work, the support of the spindle better, effectively reduce the work of the hollow shaft load. Put an end to the hollow shaft due to the large load of the twist, bending and so on.

transmission:

300, 500,750 motor reducer coupling jaw axis.

1000 by the motor, reducer, bevel gear drive screw shaft.

1200,1500 by the motor, reducer, cylindrical spur gear drive screw shaft.

Spirochetes:

By the hollow shaft and spiral blade, bracket composition. Hollow shaft is seamless steel pipe (A2 or 2 #)

Spiral blade:

For A3 steel or white cast iron parts, the wearing parts shall be replaced according to wear conditions.

Trough:

Welded by the A3 steel plate, after welding shall not crack, there is no leakage phenomenon.

Lifting institutions:

Divided into two forms:

(1) hand worm gear reducer, through the wire rope lift spiral.

(2) motor, reducer through the bevel gear screw lift spiral.

The lower bearing or the middle bearing frame, the support of the spiral rotation in two ways.

(1) intermediate shaft, support FLG-300,500,750,1000 spirals in a fixed position on the rotation.

(2) lower support: support FLG-1200, 2FLG-1200, FLG-1000, 2FLG-1200, FLG-1500, 2FLG-1500 classifier screw rotation in a fixed position.

working principle:

Working principle diagram

Grading machine is by means of different sizes of solid particles, the proportion of different, so the settling velocity in the liquid of different principles, fine ore particles floating in the water into the overflow, coarse ore particles sink in the bottom. By the spiral to the upper part of the discharge, to the mechanical classification of a grading equipment, the mill can be ground out of the powder level in the filter, and then the coarse material spin screw rotary screw into the mill inlet, the filter The fine material is discharged from the overflow pipe. The machine base with channel, the body made of welded steel plate.

FLG1200, FLG1500, FLG1200, FLG1200, FLG1200 and the horizontal plane of the inclination of 12 ° - 16 °. Motor start And then through the reducer coupling (or grinding wheel) umbrella wheel to drive the spiral rotation of the ball mill in the slurry from the front side of the mouth into the mouth into the tank, the front of the tank to form a deep pool, at this time due to spiral rotation, Pulp is affected by agitation, small particles float on the surface, from the overflow weir out of the sink, and large particles of ore deep in the bottom of the tank, the rotation of the spiral leaves to the trough of the trough, discharged from the row of ore ball mill (or Other ore plant) and then grinding.

Machine installation, operation and maintenance

(A) installation: screw classifier installation: screw classifier without inspection, no screw, you can install. The classifier should be securely mounted on the basis of the cast concrete. The basic design should have a good supporting role, to minimize the shear force on the screw

(B) of the spiral grading machine structure and working principle clear, before manipulating the machine.

1, spirochete transport before they can begin to enter the pulp, and gradually increase the amount of ore.

2, the spirals in the working state, in case of special failure (such as stuck, overload) to immediately stop immediately after the spiral body to raise the pulp surface, never allow the spiral body pressure in the pulp, the speed of the discharge valve to open, to avoid Silt.

3, re-start, the spirochete must be reduced to a certain position in order to turn the spiral body.

4, the machine in the use of such as the need to stop, you should stop the supply, to be finished after the classification of materials, no material before, to stop running.

(C) maintenance

1, where the lubrication points are sodium-based grease or calcium-based grease lubrication.

2, each class should see whether the internal lubricating oil in the oil needle line, every 6 months for 1 oil.

3, should always check the lower bearing or the middle frame bearing, bearings, seals are worn, the bearing is damaged, so that timely replacement.

4, the lower bearing bearing lubrication must be every 4 hours with a manual dry pump to the bearing pressure injection of high pressure oil to maintain the bearing sealing performance.

Product Application:

The spiral classifier is suitable for the treatment of alluvial deposits, especially for those with good mineral dissociation and flattened. For the residual plot, the slope of sand and even more than the body, the recovery rate is low. In addition, for the higher probability of ore ore, will reduce the quality of the concentrate, so the requirements of dehumidification and classification into the spiral classifier and spiral chute. Spiral chutes with the same type of spiral chute are suitable for handling fine materials and are successfully treated for extreme depleted iron ore. Spiral chute and spiral classifier are re-election equipment, its shape and working principle is basically the same, but the two in terms of structure, performance and use are very different.

1, the spiral chute groove bottom line for the cubic parabola, and the spiral section of the bottom section of the bottom of the parabola or ellipse is part of the spiral chute groove bottom wide and gentle, more suitable for processing fine particles.

2, to the mineral quality score is different, spiral chute requires high quality score, generally not less than 30%, while the spiral grading machine quality requirements are not strict, the lower limit to 10%.

3, the spiral chute is in the groove at the end were received fine, in the tailings, and the spiral grading machine is in the upper interception of the concentrate, in the trough after the tailings.

4, spiral chute selected particle size smaller than the spiral classifier, spiral chute appropriate processing particle size of 0.3 ~ 0.04mm, while the spiral classifier into the optional particle size of 2 ~ 0.074mm.

Product specifications and technical parameters:

Types of | model | Spiral diameter(mm) | Screw speed(r/min) | sink | Tilt angle(°') | Production capacity(T/D) | Drive motor | Lift the motor | weight | ||||

long(mm) | width(mm) | Overflow | Amount of sand | model | power(kW) | model | power(kW) | ||||||

High weir type single helix | FLG-5 | 500 | 8.5~11.5 | 4500 | 555 | 14°~18° | 32 | 143~261 | Y90L-6 | 1.1 | 手动 | 0 | 1600 |

FLG-7 | 750 | 4.5~9.9 | 5500 | 830 | 14°~18° | 65 | 256~564 | Y132S-6 | 3 | 手动 | 0 | 2900 | |

FLG-10 | 1000 | 3.5~7.6 | 6500 | 1112 | 14°~18° | 85 | 473~1026 | Y132M2-6 | 5.5 | 手动 | 0 | 4400 | |

FLG-12 | 1200 | 6 | 6500 | 1372 | 14°~18° | 155 | 1170~1600 | Y132M2-6 | 5.5 | Y90L-4 | 1.5 | 8800 | |

FLG-15 | 1500 | 2.5~6 | 8265 | 1664 | 14°~18° | 235 | 1140~2740 | Y160M-6 | 7.5 | Y100L1-4 | 2.2 | 11680 | |

FLG-20 | 2000 | 3.6~5.5 | 8400 | 2200 | 14°~18° | 400 | 3890~5940 | Y160L-6/4 | 11/15 | Y100L2-4 | 3 | 20450 | |

FLG-24 | 2400 | 3.64 | 9130 | 2600 | 14°~18° | 580 | 6800 | Y160L-4 | 15 | Y100L2-4 | 3 | 25650 | |

FLG-30 | 3000 | 3.2 | 12500 | 3200 | 14°~18° | 890 | 11650 | Y200L2-6 | 22 | Y113M-4 | 4 | 37000 | |