Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Sieve plate type hydraulic grading machine, also known as the Codea (Denver) type hydraulic classifier, is the use of sieve plate caused by interference settlement conditions of the equipment. The body shape for a corner cone, box with a vertical partition is divided into 4 to 8 grading room. The cross-sectional area of each chamber is 200 mm x 200 mm. Set the sieve plate at a certain height from the bottom of the room.

The plate is drilled with 36 ~ 72 sieve with diameter of 3 ~ 5mm. The pressure water is fed under the sieve plate and flows upward through the sieve. In the sieve above the suspended particles, the interference settlement stratification. The coarse particles are discharged through the center hole of the sieve plate and the discharge amount is controlled by a tapered plug.

The pulp is fed from one side and into the chambers in turn, and the ascending water velocity of each chamber is gradually reduced, thereby obtaining the product from the coarse to the fine. How to distribute the water velocity in the graded chamber has an important effect on the grading effect. Reducing the sieve and increasing the number of sieves can improve the effect to a certain extent. But uneven water velocity distribution is inevitable. Which caused the secondary reflux agitation efficiency is not high important reason.

Sieve plate hydraulic classifier has the advantage of simple structure, no power. Compared with the mechanical mixing hydraulic classifier, the height is small, easy to configure. Can be selected according to the different processing capacity, made four rooms, six rooms, eight rooms and other different specifications. This classifier in China's small and medium-sized tungsten ore concentrator application more.

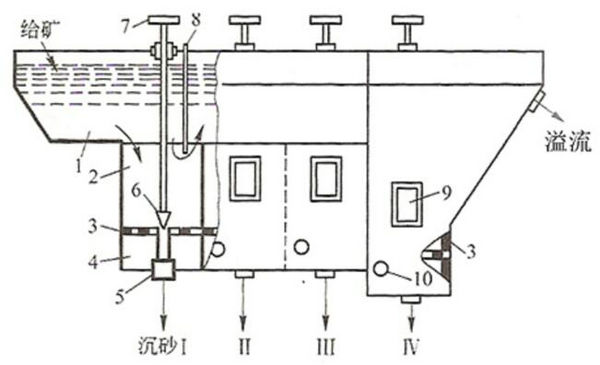

Product structure and principle:

Sieve plate type hydraulic classifier

1 - to the mine trough; 2 - class chamber; 3 - sieve plate; 4 - pressure water chamber; 5 - discharge port; 6 - row discharge adjustment plug;

8 - baffle (to prevent coarse grain chamber); 9 - glass windows; 10 - pressure water pipes

Construction of hydraulic classifier

1. To the mine tank: ore particles in the horizontal flow in the rough classification, the slurry concentration is thinner.

2. Mixing chamber: due to coarse sedimentation, grading in the pulp concentration under the conditions of the larger.

3. Classification room: in the rising water in the re-grading, can be observed by the glass window grading situation.

4. Vortex box: to the high pressure water.

5. Lifting rod: the lower end of a tapered plug, the gap size (grading ore grain thickness) by the screw to control.

6. Sediment chamber (buffer box): to prevent the sagging discharge generated when the rapid damage to the grading process to ensure the normal continuous discharge.

Detailed description:

The basic structure of the hydraulic classifier is inverted trapezoidal, the main body by the upper tank and the lower cone chamber combination. Efficient classification in the middle of the coarse grading chamber and around the ring around the fine grading class application of fluidized bed and ascending water technology to complete. The slurry is supplied to the dispensing tray at the bottom of the coarse grading chamber by a central portion of the coarse grading chamber via a special pipe. The rising water flow enters the coarse grading chamber through the annular gap between the distribution plate and the inner wall of the coarse grading chamber, and the coarse fraction is formed in the turbulent region in the lower part of the coarse grading chamber. The coarse-grained minerals settle in accordance with the requirements of the process and enter the coarse-grained discharge openings located at the middle of the bottom of the coarse grading chamber through the above-mentioned ring gap. While the fine minerals are in the way of overflow into the ring fine grading room.

Fine-grained grading chamber uses fluidized bed technology to classify fine and superfine minerals. The rising water is specially mounted on the fines

Hydraulic classifier structure and principle:

The bottom of the grading chamber is evenly divided at the bottom of the entire fine grading chamber to ensure a uniform and stable laminar fluidized bed to achieve accurate grading. The ultrafine particles enter into an annular overflow tank that surrounds the fine particle classification chamber. The fine-grained minerals settle down to the bottom of the fine-grained chamber and are discharged through a circularly distributed valve along the screen surface.

Coarse and fine particles of two grading room all discharge valve opening and closing and discharge speed are measured through the pulp density on-line measurement and regulation. In the case of known field fluid loading, coarse particles, fine and ultrafine particles (i.e., coarse grading chamber grit, fine grading chamber sagging and equipment) can be adjusted by changing the fluidized bed height and rising water Final overflow product). In addition, the concentration of the product and the flow distribution can also be in accordance with the needs of a certain range of regulation.

Product Application:

Sieve plate hydraulic classifier has the advantage of simple structure, no power. Compared with the mechanical mixing hydraulic classifier, the height is small, easy to configure. Can be selected according to the different processing capacity, made four rooms, six rooms, eight rooms and other different specifications. This classifier in China's small and medium-sized tungsten ore concentrator application more.

Product specifications and technical parameters:

Four-chamber hydraulic classifier technical parameters:

Item \ specification | Ore grain size(mm) | Concentration of ore | Rising water pressure | Sieve size (mm) | Production capacity | Dimensions(mm) |

240×240 | 0—3 | 20%~ 26% | 150~ 200 | 240×240 | 5—8 | 1818×1138×1680 |