Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Mine flotation machine is widely used in copper, lead, zinc nickel, molybdenum, gold and other nonferrous metals, ferrous metals and non-metallic mineral rough selection, selection and anti-flotation operations.

XJK-1, XJK-2, XJK-2, XJK-2, XJK-2, XJK-2, XJK-2, XJK-2, XJK-2, XJK-2, XJK- Six slots for the basic slot. XJK-1 to one, two, four slots as the basic slot, connecting a number of basic slots constitute a series of flotation machine, for rough, fine, cleaning operations.

Product structure and principle:

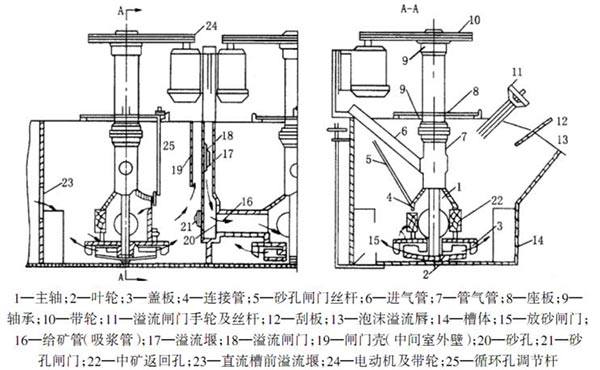

The structure of the XJK flotation machine is shown below:

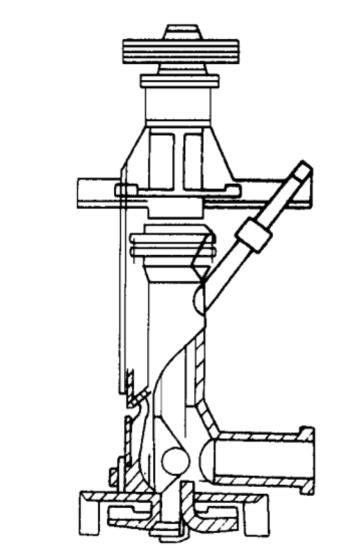

XJK Flotation Machine Vertical Shaft Assembly:

Flotation machine driven by the motor triangular drive impeller rotation, resulting in the formation of negative pressure centrifugal, on the one hand inhalation of adequate air and pulp mixture, on the one hand mixing sand washing pulp and drug mixture.

During the flotation process, the ups and downs of minerals are almost independent of mineral density. Such as chalcopyrite and quartz, the former density of 4.2, the latter is 2.68, but the heavy minerals of the chalcopyrite is easy to float, but rather sink at the bottom of the quartz. It has been found that the floatability of minerals is related to the affinity of the water disk feeder, which is easy to be wetted with water and is difficult to adhere to the bubbles. And the water affinity is small, not easy to water wet mineral, easy to float. Therefore, it can be said that the flotation is based on mineral water wetting different mineral processing methods. Generally easy to float the nature of minerals and difficult to float known as the floatability of minerals. Flotation is the use of mineral floatability difference to sort the mineral. In the modern flotation process, the application of flotation agents is particularly important, because the flotation agent treatment, you can change the floatability of minerals, flotation machine to float the minerals can be selectively attached to the bubble, so as to achieve mineral processing the goal of.

If flotation pulp contains more slime, it will bring a series of adverse effects on flotation. The main effects are the following:

① easily mixed in the foam products, so that grade grade decline.

② easy to cover the surface of coarse particles, affecting the coarse grain flotation.

③ adsorption of a large number of agents, increase the consumption of pharmaceuticals.

④ make the pulp sticky, inflatable conditions deteriorate.

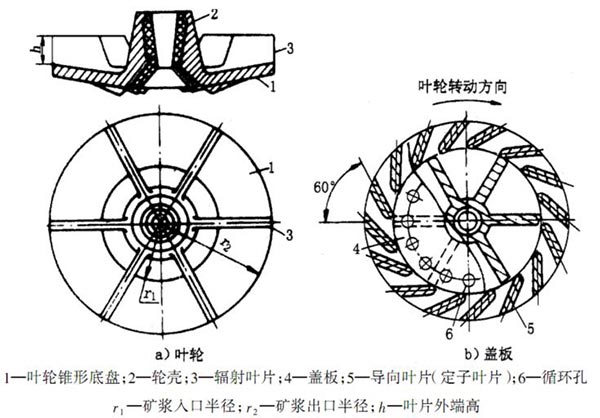

XJK flotation machine impeller cover diagram:

XJK flotation machine works:

The flotation machine is driven by the motor triangular belt drive to rotate the impeller, resulting in centrifugal action to form negative pressure. On the one hand, the suction air is mixed with the pulp. On the one hand, the mixing pulp is mixed with the medicine, and the foam is refined, Floating to the pulp surface and then forming a mineralized foam. Adjust the height of the gate, control the liquid surface, so that useful foam scraped by the scraper.

The slime and the medicament are mixed thoroughly and then fed into the bottom of the first chamber of the flotation machine. After the impeller rotates, a negative pressure is formed in the wheel chamber so that the bottom of the tank and the slurry in the tank are respectively entered by the lower suction and upper suction of the impeller The mixing zone also allows the air to enter the mixing zone along the air guide sleeve, where the pulp, air and chemicals are mixed.

Under the action of the centrifugal force of the impeller, the mixed pulp enters the mineralized area, the air forms bubbles and is crushed, fully contacted with the coal particles to form mineralized bubbles, evenly distributed under the action of the stator and the turbulence plate Cross-section, and move up into the separation zone, enrichment to form a foam layer, discharged by the bubble blowing mechanism, the formation of coal foam.

When the sorting chamber enters the floating area, the selected material is given to the six sorting points by the pulp distributor, and the weak magnetic particles are sucked on the tooth plate and rotated with the sorting ring. Non-magnetic ore particles in the gravity and the role of slurry flow through the tooth plate gap, into the lower part of the sorting ring tailings. When the sorting room is transferred to the mine cleaning position, a small amount of washing water is fed, and the mixed gangue, even the body and the sludge are washed into the tailings tank (the machine is not set in the mine), in order to improve the quality of the concentrate the goal of. When the sorting chamber is moved to a very weak position in the magnetic field (the concentrate rinse zone), the pressure water is injected and the weakly magnetic mineral particles sucked into the tooth plate into the concentrate tank. The sorting chamber is then transferred to another opposing field of magnetic field, and the sorting ring is rotated once a week, where each sorting room is repeated six times.

XJK Flotation Machine Exclusive Advantages:

1, strong performance, high efficiency

The flotation machine has an advanced grouting port, which improves the production efficiency; and the adjustment of the slurry surface is equipped with a gate device, which is mainly composed of a groove welded by a steel plate and a gate welded with a steel plate and a round bar. Machine to improve the production capacity of the role.

2, easy maintenance, low cost

As the parts of the structure design is reasonable, the components of the space between the appropriate space to facilitate the inspection of the operator; and in the parts are surrounded by high wear parts, the effective protection of the tank is not damaged damage, A certain fee.

3, work smoothly, no trouble

The use of foreign advanced technology and developed the components, with a reasonable structure, work and other advantages. Coupled with the design is reasonable, so that the gap between the impeller and the cover appropriate, no work at any problems and deficiencies, and the wear resistance of the cover is very high.

4, high wear resistance, short replacement cycle

The impeller of the float machine has been active in the machine and has played a role in removing the accumulated material and debris, thereby reducing the damage to the parts due to debris and the impeller of the stirring device is made of ground rubber, Strengthen the wear resistance, shorten the replacement cycle.

5, the use of a long time, impact resistance

The use of excellent quality steel to do skeleton materials, wear-resistant anti-corrosion oil resistance as excellent wear-resistant layer, the use of high-performance adhesive by a special combination of vulcanization process. Therefore, it has good abrasion resistance, impact resistance, tear resistance and chemical stability.

6, advanced technology, unique structure

The rotor has a unique skeleton structure and advanced liquid-phase nano-wear-resistant rubber production technology consisting of flotation machine rotor, and the rotor structure design obtained national patent certification. In use is more reliable, stable and other advantages.

Installation of XJK flotation machine

The flotation machine itself has good stability, so the installation does not require a special basis, but must ensure that the level of overflow weir. The installation of the flotation machine is usually carried out according to the following steps (for example, type A flotation machine):

1, before the installation of the inspection. Flotation machine installed before the packaging of the warranty and anti-corrosion oil removed, check the packing list carefully check the various parts and parts, if found a defect should try to eliminate. If necessary, disassemble cleaning, calibration and adjustment, and check that all parts are complete.

2, the inspection of complete sets of components. Flotation machine should check the number of parts before installation, to determine the required left and right installed program. According to the total flotation machine check zero, the number of parts and so on.

3, flotation machine installation deviation check.

(1) the installation of vertical and horizontal center limit deviation of ± 3mm, and installed in the same center line on the flotation machine, the center straightness tolerance of 3mm;

(2) installation height limit deviation of ± 5mm, and installed in the same centerline flotation machine, the relative elevation difference of not more than 3mm;

(3) the installation of vertical and horizontal horizontal tolerance of 0.30 / 1000.

4, the assembly and installation of the tank.

(1) the tank body in the direction of the body should be maintained in the horizontal level;

(2) into the row of flotation machine installed in the tank after the overflow weir should be level, height difference of not more than 5mm;

(3) into the row of flotation machine installed in the tank into the groove relative position difference of not more than 5mm;

(4) the connection of the tank body using welding;

(5) After positioning the tank, it should be welded together with the mounting plate, platform or embedded parts.

5, vertical axis part of the inspection and transmission assembly.

(1) Rotor (impeller) and the stator (cover) between the radial and axial clearance in line with the requirements of the drawings to ensure the flexibility when the impeller idling;

(2) vertical shaft drive installation must be corrected when the motor center line vertical, motor triangular pulley and the spindle on the V-belt pulley height is consistent and the degree of tension of the set of V-belt pulley.

6, the installation of foam scraper.

(1) correct the linearity and level of the foam scraper;

(2) check the scraper bearing installation is correct to prevent the card shaft, scraper rotary shaft bearing coaxial tolerance of Φ2mm;

(3) scraper rotary shaft and overflow weir should be parallel to the parallelism tolerance of 3mm;

(4) The gap between the blade blade and the weir is 4-6 mm.

7, the requirements of the middle room.

(1) the installation of the middle chamber and the tank and the gate and the middle of the room between the contact should be close to each other without gaps;

(2) slurry slurry to adjust the gate after installation to ensure flexibility.

Product Application:

Mine flotation machine is widely used in copper, lead, zinc nickel, molybdenum, gold and other nonferrous metals, ferrous metals and non-metallic mineral rough selection, selection and anti-flotation operations.

Product specifications and technical parameters:

Models and Specifications | Tank volume(m3) | Impeller diameter(mm) | Production capacity(m3/min) | Impeller turns(r/m) | Scraper number of revolutions(r/m) | Impeller motor | Scraper motor | Dimensions fourslots one(mm) | Equipment(T) | ||

Model | power(KW) | Model | power(KW) | ||||||||

XJK-1 | 0.13 | 200 | 0.05-0.16 | 600 | 17.5 | Y90L-4 | 1.5 | Y801-4 | 0.55 | 2100×865×900 | 0.35 |

XJK-2 | 0.23 | 250 | 0.12-0.28 | 500 | 17.5 | Y90L-4 | 1.5 | Y801-4 | 0.55 | 2625×1130×1290 | 0.41 |

XJK-3 | 0.35 | 300 | 0.15-0.5 | 470 | 17.5 | Y100L1-4 | 2.2 | Y801-4 | 0.55 | 3012×1350×1327 | 0.45 |

XJK-4 | 0.62 | 350 | 0.3-0.9 | 400 | 16 | Y100L2-4 | 3 | Y90S-4 | 1.1 | 3798×1464×1530 | 0.85 |

XJK-5 | 1.1 | 500 | 0.6-1.6 | 330 | 26 | Y132M-6 | 5.5 | Y90S-4 | 1.1 | 4679×1820×1942 | 1.24 |

XJK-6 | 2.8 | 600 | 1.5-3.5 | 280 | 26 | Y160L-6 | 11 | Y90S-4 | 1.1 | 7750×1600×1100 | 2.43 |

Ordering Information:

1, the order must indicate the name, model, specifications.

2, need to explain to the mine direction, otherwise the left by the material manufacturing.

3, in the mine pipe, discharge pipe according to user requirements and delivery of the flow chart accessories installed, or not supply.