Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

The dry magnetic separator is a magnetic mineral processing machine for sorting dry magnetic minerals. When the liquid is used as a thinner to improve the sorting efficiency with respect to the wet sorting machine, the dry magnetic separator requires The sorted minerals are dry and the particles can move freely into an independent free state, otherwise it will affect the magnetic separation effect, and even cause irreseable consequences.

The magnetic separator for the size of 3mm below the magnetite, pyrrhotite, roasting ore, ilmenite and other materials, wet magnetic separation, but also for coal, non-metallic minerals, building materials and other materials in addition to iron operations. Especially for iron-free operations in anhydrous areas; refractory materials and other materials in addition to iron operations.

Dry-type permanent magnet magnetic separator is my company's newly developed high-performance magnetic separation equipment. All the magnetic system is made of high-performance rare earth NdFeB material and high quality ferrite material. After the clever open magnetic circuit design, the maximum magnetic induction intensity of the cylinder table sorting area is more than 800 mT, and the magnetic field strength is 3 -5 times, the magnetic field force of the sorting area can reach the magnetic level of the electromagnetic magnetic separator.

The sorting cylinder is made of wear-resistant stainless steel, and the sorting minerals are uniformly distributed to the upper part of the sorting cylinder through the vibrating feeder. The rotating cylinder removes the non-magnetic material from the cylinder and the magnetic material is subjected to strong magnetic field Suction to the cylinder, with the sub-board is very convenient, accurate magnetic, non-magnetic materials separation. Strong magnetic field force for the cylinder magnetic separator sorting, weak magnetic minerals into reality.

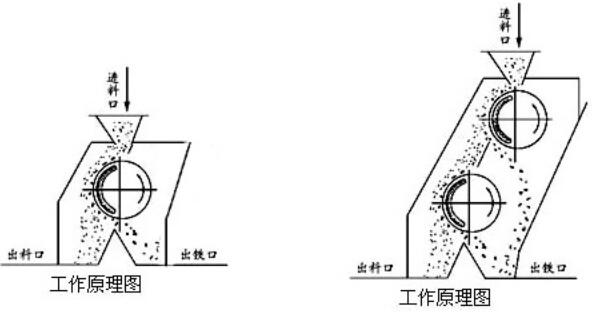

Product structure and principle:

Dry magnetic separator is commonly used iron ore equipment and manganese ore equipment, the mainstream of the strong magnetic separator mineral processing equipment. The dry magnetic separator is a magnetic mineral processing machine for sorting dry magnetic minerals. When the liquid is used as a thinner to improve the sorting efficiency with respect to the wet sorting machine, the dry magnetic separator requires The sorted minerals are dry and the particles can move freely into an independent free state, otherwise it will affect the magnetic separation effect, and even cause irreseable consequences. Dry magnetic separator for the size of 3mm below the magnetite, pyrrhotite, roasting ore, ilmenite and other materials, wet magnetic separation, but also for coal, non-metallic minerals, building materials and other materials in addition to iron operations.

Dry magnetic separator works:

After the pulp into the tank into the tank, the water in the pipeline to the role of water, the ore was loose into the tank to the mining area. In the role of the magnetic field, the magnetic particles are magnetically aggregated to form a "magnetic group" or "magnetic chain", "magnetic group" or "flux chain" in the slurry by the magnetic force, to the magnetic pole, and was adsorbed on the cylinder The Since the polarities of the poles are alternately arranged in the direction of rotation of the cylinders and are fixed at work, the "magnetic masses" or "fluxes" are intertwined due to alternating magnetic poles when the cylinders rotate In the "magnetic group" or "flux chain" in the gangue and other non-magnetic minerals in the flip off, and ultimately sucked on the surface of the cylinder "magnetic" or "magnetic lotus" is the concentrate. The concentrate is transferred to the concentrate tank under the action of the flushing water discharged from the unloading water pipe with the cylinder to the weakest edge of the magnetic system. If it is a full magnetic roller, the unloading is carried out with a brush roller. Non-magnetic or weak magnetic minerals are left in the pulp with the pulp out of the tank, that is, tailings.

Dry magnetic separator magnetic system, the use of high-quality ferrite material or with rare earth magnet composite, cylinder table average magnetic induction strength of 100 ~ 600mT. The magnetic separator has the advantages of simple structure, large processing capacity, convenient operation and easy maintenance. Dry magnetic separator equipment has a stir-off magnetic field and high separation factor characteristics, advanced structure, light weight, reliable operation, easy maintenance. Dry magnetic separator is very suitable for dry and dry areas, saving water resources, reducing the cost of mineral processing, for the ultra-poor magnetite mining and utilization opened up a new way.

Dry magnetic separator equipment handling capacity, sorting mineral particle size range, high separation accuracy, no clogging; simple structure, easy maintenance, power consumption is only 20% of the electromagnetic magnetic separator.

Dry magnetic separator magnetic system, the use of high-quality ferrite material or with rare earth magnet composite, cylinder table average magnetic induction strength of 100 ~ 600mT. According to user needs, can provide a variety of different surface of the magnetic election cylinder. The magnetic separator has the advantages of simple structure, large processing capacity, convenient operation and easy maintenance.

Dry magnetic separator is widely used in sorting less than 2-3 mm of weak magnetic minerals and rare metal ore re-selection. It has three pieces (diameter φ = 900 mm), double disc (φ = 576 mm) and three (φ = 600 mm). Magnetic field strength of up to 880-1440 kA / m.

Factors affecting the dry magnetic separator

Factors affecting the dry-type magnetic separator are ore properties (grade, magnetic, grain size and moisture, etc.), equipment performance and operational level. Under certain conditions of operating performance, the operational adjustment should be based on the nature of the ore being processed and the requirements for the product specification. Operation adjustment factors are roller speed, baffle position and the size of the ore to the reasonable adjustment of these three factors, can improve the magnetic selection indicators.

The adjustment of the speed of the roller is to determine the size of the centrifugal force and the strength of the magnetic particles. Increase the roller speed, centrifugal force increases, magnetic rollover effect is also enhanced, is conducive to improving the quality of concentrate and processing ore. But the speed to speed up, throwing a lot of tailings, tailings taste also increased; on the contrary, reduce the speed, its role is just the opposite, concentrate grade and tailings grade will be reduced.

Baffle adjustment, mainly refers to the upper and lower tailings baffle, adjust the baffle position can control the tailings grade level (or tailings size). The closer the baffle is, the higher the tailings and the higher the tailings. At the same time the amount of ore will be reduced accordingly, the ore grade also increased; baffle from the cylinder surface farther, the effect is just the opposite. Of course, the changes in the amount of ore and the mineral grade will inevitably affect the quality of the concentrate, such as the middle roller in the small amount of grain, high taste, the lower roller concentrate grade is also easy to improve, which in the treatment of coarse ore , Especially obvious.

To the amount of ore regulation, and its size determines the thickness of the material layer on the roll, to the large amount of ore, the material layer thickness, in the material layer of magnetic particles on the surface of the magnetic force is small, easy to be thrown into the tailings , Increase the tailings grade. When dealing with fine grain level, it will also reduce the taste of the concentrate, this time should be reduced to the amount of ore to ensure the required selection of indicators.

The effect of the selected particle size on the sorting index of the dry-type double-cylinder permanent magnet magnetic separator is also great, and the index of the coarse-grained grade is better than the index of the sorting fine-grained scale. This is mainly due to the coarse particle size, because the material is coarse, moisture and mud content less, easy to spread on the cylinder, is conducive to the separation of magnetic ore particles and non-magnetic particles, but also help to improve the treatment ability. But also to the amount of fluctuations in the selection effect of little effect. The ore is thick and has a large weight, and the centrifugal force on the roll is large. Therefore, the drum speed must be strictly controlled. And pay attention to changes in speed with the timely adjustment of the location of the baffle. When the speed is high, the baffle should be far from the drum, the speed is low, can be near. When dealing with fine-grained level, due to the fine particle size, water and mud more, easy to fight the group, in the tube surface is difficult to spread, the group of mineral particles in the role of centrifugal chanting into the tailings , So that the tail grade is high. Mineral particles are thin, under the action of the magnetic field, the formation of flux, coupled with the adhesion of water and mud, so that the magnetic chain in the magnetic process is difficult to disperse and discharge sludge. Such a flux into the concentrate will reduce the grade of concentrate, and the fine particles of small particles, by the centrifugal force is also coarse particles of small, so tailings throwing is also narrow, easy to baffle cut ore. In order to reduce this effect, the ore can be graded in advance according to the size of the size of the coarse and fine particles at different levels according to different conditions were dealt with. When handling the fine grade, the ore quantity should not be too large, and the roller speed should be increased appropriately. This will reduce the thickness of the material layer, strengthen the centrifugal force and magnetic rotation, destroy the magnetic reunion and throw the gangue into the tailings. As the fine-grained tailings are narrower and the grade of the tailings is not significantly different from the distance from the crests, the baffle can be close to the bark, so that the tailings are not much increased and the taste of the concentrate is improved Is good for it.

Production practice has proved that, due to the selection of particle size on the dry magnetic separation index of a great impact, in order to reduce this effect, in actual operation according to the specific circumstances, Beijing iron ore into the selected size of 200% of the 25% 200 mesh content of 5% -8% coarse level and -200 mesh content of 50% -60% fine level, the two levels were selected, get better sorting indicators.

Ore moisture has a certain effect on the dry magnetic separation effect, especially for the fine grain level selection is serious. Because the water will improve the "magnetic group" of the bond, so that "magnetic group" with a more solid, and easy to stick in the tube skin, although the increase in centrifugal force, can not improve the indicators, and sometimes more worsening. Therefore, when the rainy season when the ore water is large, may be appropriate to increase the proportion of lump ore, so that the ore water content, the relative reduction in the amount of mud, when the water significantly affect the selection of indicators, the operation to reduce the amount of ore and to ensure qualified Concentrate products to adjust the way. When the amount of water is less than 2%, there is no significant effect on the selection index. When the water content is less than 2.5%, there is no significant effect on the selection index.

The size of the magnetic properties of the ore also affect the magnetic parameters, the magnetic rate is high, the operation should be to ensure the quality of the concentrate on the basis of minimizing tailings grade, improve the recovery rate of beneficiation. Magnetic rate is low, the operation should be to ensure that the main grade concentrate, but also pay attention to reduce the tailings grade. In the case of

Precautions:

Dry-type magnetic separator routine maintenance is also very important, permanent magnetic dry magnetic separator because of its own work requirements and strength of the situation, its daily maintenance is very important. In particular, the replacement of lubricating oil is particularly important.

Dry magnetic separator used in the process should pay attention to:

① permanent magnetic cylinder wall wear, if found to wear off after the serious wear and tear, should be promptly processed or re-hanging glue.

② inside the box with or without iron and other debris fall, should be immediately removed after the discovery.

③ motor, continuously variable transmission and permanent cylinder bearing overheating, bearing temperature rise is generally not more than 35 ° C, the maximum shall not exceed 65 ° C.

④ the tension of the transmission belt, the degree of tightening to be appropriate.

⑤ wear the belt and found a serious wear and tear, should choose the same length of the belt group replacement.

⑥ whether the lubrication point is sufficient grease, CVT oil level is normal, if found inadequate, should be added in time.

The equipment should be regularly repaired, adjusted or replaced parts that affect its performance and make the equipment not working properly.

A regular work on the maintenance of a permanent magnet dry magnetic separator. Maintenance work directly affects the operation rate and service life of permanent magnet dry magnetic separator. In order to detect defects in time to ensure that the normal operation of the machine, in addition to daily maintenance, but also need to regularly shut down maintenance, (recommended once a month) on the important components such as cylinder wall, box, belt and other serious inspection, For a detailed record. In accordance with the shortcomings of the situation in order to properly handle and arrange the repair and overhaul plan. In the case of

Product Application:

Dry magnetic separator is commonly used iron ore equipment and manganese ore equipment, the mainstream of the strong magnetic separator mineral processing equipment. This series of dry magnetic separator for refractory materials, chemical materials, grain and oil machinery, abrasive, ceramics, metallurgy, cement, powder metallurgy, rubber, ore and other materials in addition to (optional) iron use, , Crusher, ball mill supporting the use.

Product specifications and technical parameters:

Model\ parameter | Cylinder diameter(mm) | Cylinder length(mm) | Processing capacity(m3/h) | Motor Power (Kw) | Dimensions (mm) | weight (Kg) |

CT6018 | 600 | 1800 | 40 | 2.2 | 600x1800 | 800 |

CT7522 | 750 | 2200 | 60 | 3 | 750x2200 | 1500 |

CT7526 | 750 | 2600 | 80 | 4 | 750x2600 | 1900 |

CT9022 | 900 | 2200 | 95 | 4 | 900x2200 | 2200 |

CT9026 | 900 | 2600 | 120 | 5.5 | 600x2600 | 2600 |

CT1024 | 1050 | 2400 | 150 | 7.5 | 1050x2400 | 3000 |