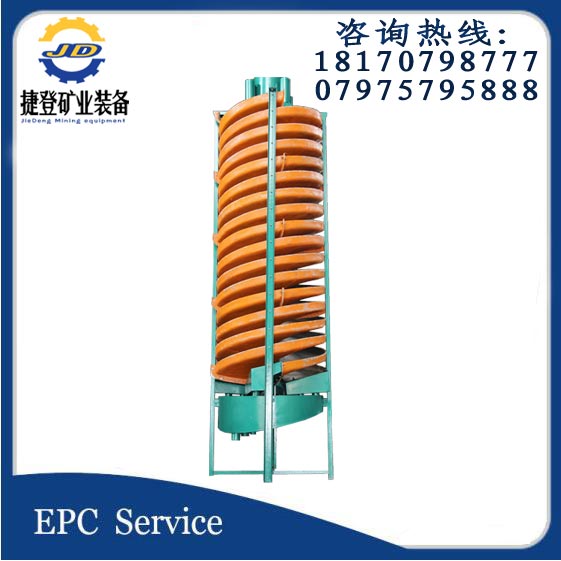

Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Fiberglass spiral chute with the domestic advanced level of efficient re-election of new equipment. Iron, tin, tungsten, tantalum, niobium, gold mine, coal mine, monazite, rutile, zircon and other metals with high specific gravity, non-metallic minerals, metallurgical Department of the organization of scientific research, design, universities and factories and mines and other units through the identification, that the equipment performance, select the indicators of advanced, to determine the use of mass production to promote. The equipment is now in the colored, ferrous metal mine a large number of applications, and access to the Ministry of Metallurgical Science and Technology Research Award. Ordinary glass fiber reinforced plastic spiral chute due to water flow in the rotary motion to the outer edge of the expansion of the results; near the inner layer of laminar flow often occurs dehydration phenomenon. Resulting in difficult to effectively carry out stratification, the increase in ore, concentrate quality decline.

I plant research to take in the groove surface by adding a groove to improve the situation, effectively provide the enrichment of minerals, increase the recovery of heavy minerals. Iron, tin, tungsten, tantalum, niobium, gold mine, coal mine, monazite, rutile, zircon and other metals with high specific gravity, non-metallic minerals, metallurgical Department of the organization of scientific research, design, universities and factories and mines and other units through the identification, that the equipment performance, select the indicators of advanced, to determine the use of mass production to promote.

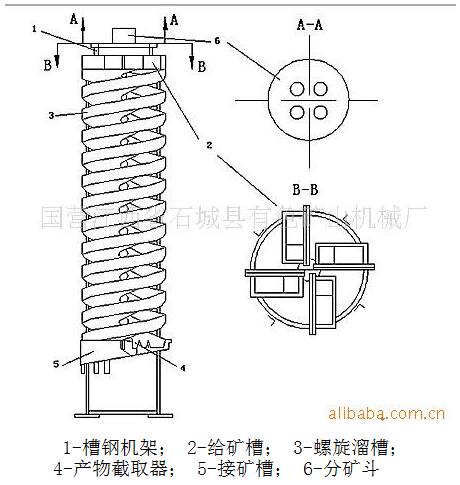

Product structure and principle:

Fiberglass spiral chute by the ore divider, to the mine trough, spiral groove, product cutting slot, product gathering bucket and slot bracket (including the cross or tripod) and other six parts. The spiral groove connected by the spiral piece is the main part. Spiral pieces are made of glass fiber reinforced plastic (glass fiber reinforced plastic), tied together by bolts, spiral groove on the selection of a layer of prefabricated wear layer. It has the advantages of light, strong, durable consumer goods. Spiral groove at the top of the multi-tube to the ore divider sub-mine uniform, easy to control. The miner is freely placed on the cross (or tripod) of the table. The homogenized pulp is slowly fed to the spiral groove surface by means of a feed tank mounted at the head end of the spiral groove for sorting. The end of the spiral groove is fitted with a new product with a valve block. The new product is divided into three (or four) new products by grade. Use the position of the regulating valve block to change the interception width of each new product. The new product gathering bucket is a concentric circular barrel, will be intercepted long mine were collected and exported. The cross-section of the spiral chute, the slope of the curve changes particularly suitable for fine particles of material selection. The spiral chute has the advantages of simple structure, no moving parts, light weight, noisy noise, easy installation and maintenance.

1-channel steel rack; 2-way tank; 3-spiral chute;

4 - product interception device; 5 -

First, use and characteristics:

FRP rotary chute is a combination of spiral concentrator, shaker, centrifugal concentrator is characterized by the concentrator for production, research and one of the new re-election equipment.

This equipment is the ideal selection for tantalum, niobium, tin, tungsten, gold, titanium, iron and other minerals with a specific gravity greater than 1.

The equipment has the characteristics of high enrichment ratio, high recovery rate, small water consumption and less adaptability and strong adaptability.

Second, the main structure:

Rotary spiral chute, mainly by the rack, chute, access to the tank and drive the four major components.

Third, the installation:

The installation procedure and requirements for the spiral chute are as follows:

1, first check the quality of glass fiber reinforced plastic spiral (especially the quality of the work surface), size and shape to meet the requirements before assembly.

2, the screw on the joint bolt hole is generally pre-equipped with a good factory. If the factory is not processed, it is required to drill holes on the same plate to ensure good interchangeability.

3, with bolts will be five laps spiral pieces connected into a group of spiral groove, placed horizontally, adjacent two flanges connected to the smooth transition within the surface prevail, the connection should pay special attention to the lower surface of the film should not be lower than the corresponding sub-surface. Along the direction of the direction. (Groove width direction) from the outer edge of the alignment shall not allow the outer edge of the next piece, so the purpose of installation is to prevent the occurrence of mine spatter. When the joints are sewn, use the putty to smooth.

4, will have been connected to a group of five (or two, three) spiral groove spin together, distributed into the required shape.

5, the four (three) columns were installed in four (or three or two) spiral groove, with bolts to the spiral groove and pillar fixed, and then install the cross (tripod), so that each head spiral along the circle Uniform, and finally spin all the bolts. After installation. Spiral pieces to maintain the natural shape, not a significant variant.

6, will be to the mine trough and product cutting slot were installed in the first and the end of the spiral groove to ensure that the joints do not leak tightly. If there is a gap, need to use paint seal. To ensure smooth transition of the groove surface.

7, to the ore sprinkler and product collection bucket and the slot bracket is not connected, free to place on the bracket, the installation should pay attention to the position is put. The individual tubes of the dispenser should be aligned with the corresponding ditch.

8, the spiral chute foundation generally do not need to be fixed, but should be placed on the same level of four (three) plane basis, after installation, to check the vertical groove of the spiral groove is vertical, you can adjust the lead below the column lead Sag. Spiral chute to the appropriate height at the operating platform, spiral chute pillars and the platform to be properly connected.

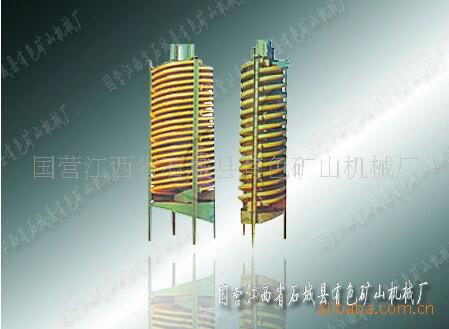

9, a large number of industrial use, should be grouped configuration, with a multi-tube sub-mineralizer to the mine, spiral chute should be arranged in a row to save the area. (Pictured)

Fourth, use:

1. The main parameters of the spiral chute selection are the ore volume and the ore concentration. The stability of the ore volume is more important than the stability of the ore concentration. Practice has proved that as long as the volume of ore to a constant, to the concentration of a certain range of fluctuations in the selection results have little effect.

2, spiral chute selection process is stable, easy to control. The ore volume is LL-900 per 1.2-1.8 cubic meters per hour, LL-1200 per hour per minute 2.5-3.5 cubic meters. Volume size can change the distribution of minerals along the spiral groove width characteristics, to try to control stability, allowing fluctuations in the range should be less than ± 5%, the general use of constant pressure to the mine.

3, to the ore concentration to allow a wide range of changes, generally 30% to 60% to be determined by experiment. Roughing to the ore concentration can generally be 30% to 50%, select the ore concentration can be selected in the range of 40% to 60%. When the selection effect is similar, it is appropriate to use high concentration to improve the handling capacity of the equipment.

4, in order to make the spiral chute normal operation, in the pulp into the spiral chute should be strictly before the slag treatment, so as not to large particles and debris in the spiral groove surface, destruction sorting.

5, adjust the product cut the slot on the valve block position can change the product yield and grade. The interception width of each product must be experimentally determined, the valve block position is determined not to arbitrarily change.

6, spiral chute to the mine should also pay attention to whether the mine is covered with the entire spiral groove surface, if found to have the phenomenon of foreigners have to try (such as water red, etc.) to correct.

7, the operation should always check the spiral groove above the phenomenon of accumulation, found that the accumulation should be cleaned in time. Each class should rinse the tank surface once with water to remove the debris accumulated in the tank surface to ensure the normal flow of the mine.

Fifth, the use of points:

a Rotating spiral chute The direction of rotation of the vertical axis must be consistent with the flow direction of the selected slurry.

b the final cut off the sub-concentrate, in the mine and tailings a variety of products.

c to the ore to be uniform, to the ore concentration to 30-45% is appropriate.

After the mine is stopped, the helical work surface must be rinsed.

The company in the original spiral chute on the basis of the spiral chute by adding a groove on the way to increase the efficiency of beneficiation recovery. Through the experimental study found that the new generation of slotted spiral chute with the use of the original increase of 10%.

The slurry flows near the front edge of the slurry, and the thickening of the ore layer enhances the loose layering effect. The coarse-grained light minerals precipitated from the ore belt move over the groove to the outer edge and the bottom heavy minerals flow in the groove edge. The results reduce the amount of ore in the ore and improve the recovery rate of the concentrate metal. The following table lists the industrial test results (a rough and a fine process) for the treatment of the gravel and the chute of the chandelite.

Chute type | Give ore grade | Concentrate% | In the mine% | Tailings% | Concentrate recovery rate% | Sorting efficiency% | |||

Yield | grade | Yield | grade | Yield | grade | ||||

Plus groove | 33.48 | 35.27 | 55.23 | 29.20 | 27.02 | 35.53 | 17.19 | 58.18 | 38.53 |

Do not add groove | 33.68 | 33.97 | 53.67 | 38.02 | 27.61 | 28.01 | 17.66 | 54.13 | 32.26 |

Without grooved spiral chute blades

With slotted spiral chute blades

Assembly drawing

Product Application:

FRP rotary chute is a combination of spiral concentrator, shaker, centrifugal concentrator is characterized by the concentrator for production, research and one of the new re-election equipment.

This equipment is the ideal selection for tantalum, niobium, tin, tungsten, gold, titanium, iron and other minerals with a specific gravity greater than 1. Is now widely used in iron, desulfurization.

The equipment has the characteristics of high enrichment ratio, high recovery rate, small water consumption and less adaptability and strong adaptability.

Product specifications and technical parameters:

model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

Outside diameter (mm) | 1500 | 1200 | 900 | 600 | 400 | |

Pitch (mm) | 540.720 | 900,720,540 | 675,540,405 | 450,360, 270 | 240,180 | |

Distance ratio (pitch / diameter) | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.6,0.45 | |

Horizontal inclination (degrees) | 9° | 9° | 9° | 9° | 9° | |

Maximum number of screw heads per set | 4-2 | 4-2 | 4-2 | 3 | 2 | |

Grain size (mm) | 0.3-0.02 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 | |

Concentration of ore(%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 | |

Production capacity (tons / hour) | 8-6 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 | |

Dimensions | Long (mm) | 1560 | 1360 | 1060 | 700 | 460 |

Width (mm) | 1560 | 1360 | 1060 | 700 | 460 | |

High (mm) | 5230 | 5230 | 4000 | 2600 | 1500 | |

Weight (kg) | 800 | 600 | 400 | 150 | 50 | |