Welcome to Jiangxi Jiedeng Mining Machinery Co., Ltd. official website!

Product Overview:

Fine sand recycling machine, also known as fine sand collection machine, sand extraction machine, tailings dryers, fine sand recovery device, fine sand recovery equipment.

The main role of the tailings reclaimer is to clean up the gravel, dehydration, grading, can be a good recovery of the traditional sand making industry in the sand washing machine lost a large number of fine sand, to enhance economic efficiency, while reducing the tailings processing costs and Loss of fine sand will cause environmental pollution, damage.

The vast majority of the existing artificial sand production line using wet production process, regardless of what form of sand washing machine, its biggest drawback is the fine sand (0.15mm above the particles) the loss of serious, and some even lost more than 20% , Which not only the loss of serious, but also seriously affect the grading of the sand with equipment, resulting in unreasonable gradation, fineness modulus rough, greatly reducing the quality of the system of sand products. Too much fine sand emissions, but also cause environmental pollution - the company absorbs foreign advanced technology, combined with the actual situation of sand powder and the design of the advanced level of fine material extraction device, widely used in hydropower aggregate aggregate processing System, glass raw material processing system, artificial sand production line, coal preparation plant coarse coal slurry recovery and environmental protection project (mud purification), etc., can effectively solve the problem of fine sand recycling.

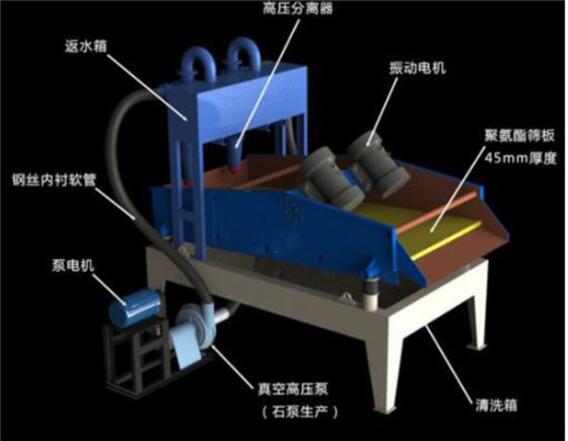

Product structure and principle:

1. Structure: by the motor, slurry pump, cyclone (high pressure separator), dehydration screen, cleaning tank, back to the box and other components.

2. Working process: the pump will be transported to the cyclone mixture of water, centrifugal grading concentrated sand by the sag laceration to the vibrating screen, the shaker after the shaker, fine sand and water effective separation, a small amount of fine sand, Return to the tank and then back to the cleaning tank, cleaning tank surface is too high, the discharge port by the discharge. Linear shaker recovery material weight concentration of 70% -85%. Adjust the fineness of the modulus can be changed by changing the pump speed, change the mortar to try to adjust the overflow water, replace the sand mouth to achieve. Thus completing the cleaning, dehydration and grading three functions.

Fine sand recycling machine features:

1, the traditional artificial sand wet processing technology, artificial sand washing mud, dehydration using the spiral sand washing machine, artificial sand in the loss of fine sand almost can not control. The use of the fine sand recovery system, can effectively reduce the amount of fine sand loss, so that it is controlled within 5% -10%, a good solution to the artificial aggregate processing system in the finished product sand fineness modulus is high, Stone powder content is low problem.

2, the use of polyurethane screen shaker than other types of screen life longer, and will not plug the hole.

3, fine particles are fully recovered, reducing the sedimentation tank workload, reducing the sedimentation tank cleaning costs.

4, the flow of lined with polyurethane, to improve the service life of the entire device can be successfully completed slurry concentration, liquid clarification and so on.

5, the maximum recyclable emissions of 85% of the total fine particulate material, with other equipment unparalleled technical and managerial advantages.

6, to reduce the material stacking time, can be directly transported, supply the market.

7, according to the different requirements of users, the design of different solutions.

Fine sand recovery machine installation steps:

1, the equipment arrived at the scene, the user inventory by inventory check acceptance.

2, the first washing tank placed in the pre-watering concrete foundation, according to the tank frame to find the level of the above, requiring four errors within ± 2mm.

3, the installation of dehydration sieve, four support beam loaded spring on the bearing seat, the spacing should be basically equal to the bottom of the bearing should be parallel to the rubber spring and the ground plane to be vertical, tighten the clamp bolt, then the motor line.

4, the installation of the pump; the pump placed on the foundation, the base after leveling with the ground pad real. Pump front end installed valve, inlet pipe and washing tank, outlet pipe to find alignment and welding must not leak, the ground after the second grouting dry fastening bolts. The motor should first turn the power line to try the direction of rotation, to match the direction of the pump, and then docked with the flange, find and then tighten the motor anchor bolts. Pump can not be empty load operation.

5, the cyclone: the cyclone installed in the return box on the channel bearing on the return pipe and the outlet docking, the lower end of the elbow into the back of the box and welded with the cover plate, sand Recycling the front end of the swirler, with bolts and fastening. Fitted Φ76mm into the rubber tube, the lower end connected with the pump outlet and wire hoop tight.

6, equipped with overflow rubber tube and according to the scene into the sink.

Product Application:

The fine sand recovery machine can be used for the dehydration of the ceramic raw material processing system, the tailings recovery of the concentrator, the processing system of the quartz sand, the processing system of the gravel material of the hydropower station, and so on, which can effectively solve the problem of the recovery of fine sand and fine material.

For example, some of the ceramic materials used in the dehydration of the vacuum filter, large investment, power consumption, the need to frequently replace the filter cloth, etc., the use of special inconvenience, with a fine sand recycling machine can replace the filter, to the material Dehydration, to dry pile and transport requirements, and small sand recycling machine investment is small, power consumption is small, easy to use, is the enterprise to reduce costs to protect the environment to improve the return on investment of choice.

The fine sand recovery function can effectively reduce the loss of fine sand, effectively reduce the content of stone powder in the tail water, and solve the problem that the finished product sand granularity is high and the content of stone powder is low. In the country to promote environmental protection and conservation of the market situation, the use of fine sand recovery device can not only recover more effective resources, cost savings, but also contribute to the protection of social environment for the country to develop efforts while maintaining the home environment.

Product specifications and technical parameters:

model | Water pump | Splitter specification(mm) | Dehydration sieve | Processing capacity (m3/h) | weight(kg) | ||

power(kw) | Material | Material | power(kw) | ||||

LZ250 | 7.5-11 | Cr26 | 250 | Imported polyurethane | 2×0.55 | 30-80 | 2050 |

LZ300 | 11-15 | Cr26 | 300 | Imported polyurethane | 2×0.75 | 40-100 | 2200 |

LZ350 | 15 | Cr26 | 350 | Imported polyurethane | 2×0.75 | 70-130 | 2555 |

LZ550 | 15-22 | Cr26 | 550 | Imported polyurethane | 2×1.1 | 100-220 | 3250 |

LZ650 | 18.5-30 | Cr26 | 650 | Imported polyurethane | 2×1.1 | 120-272 | 3945 |

LZ750 | 37-55 | Cr26 | 750 | Imported polyurethane | 2×1.5 | 180-350 | 4900 |

LZ900 | 55-65 | Cr26 | 900 | Imported polyurethane | 2×2.2 | 250-500 | 5650 |

LZ1200 | 60-74 | Cr26 | 1200 | Imported polyurethane | 2×2.2 | 500-650 | 6750 |